Traction pull rod device of railway wagon bogie

A technology for traction rods and railway freight cars, which is applied to bogies, railway car body parts, transportation and packaging, etc., can solve the problems of inconvenient installation of traction rods and heavy structure, avoid fretting wear phenomenon, and meet the requirements of lateral displacement. , The effect of eliminating fretting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

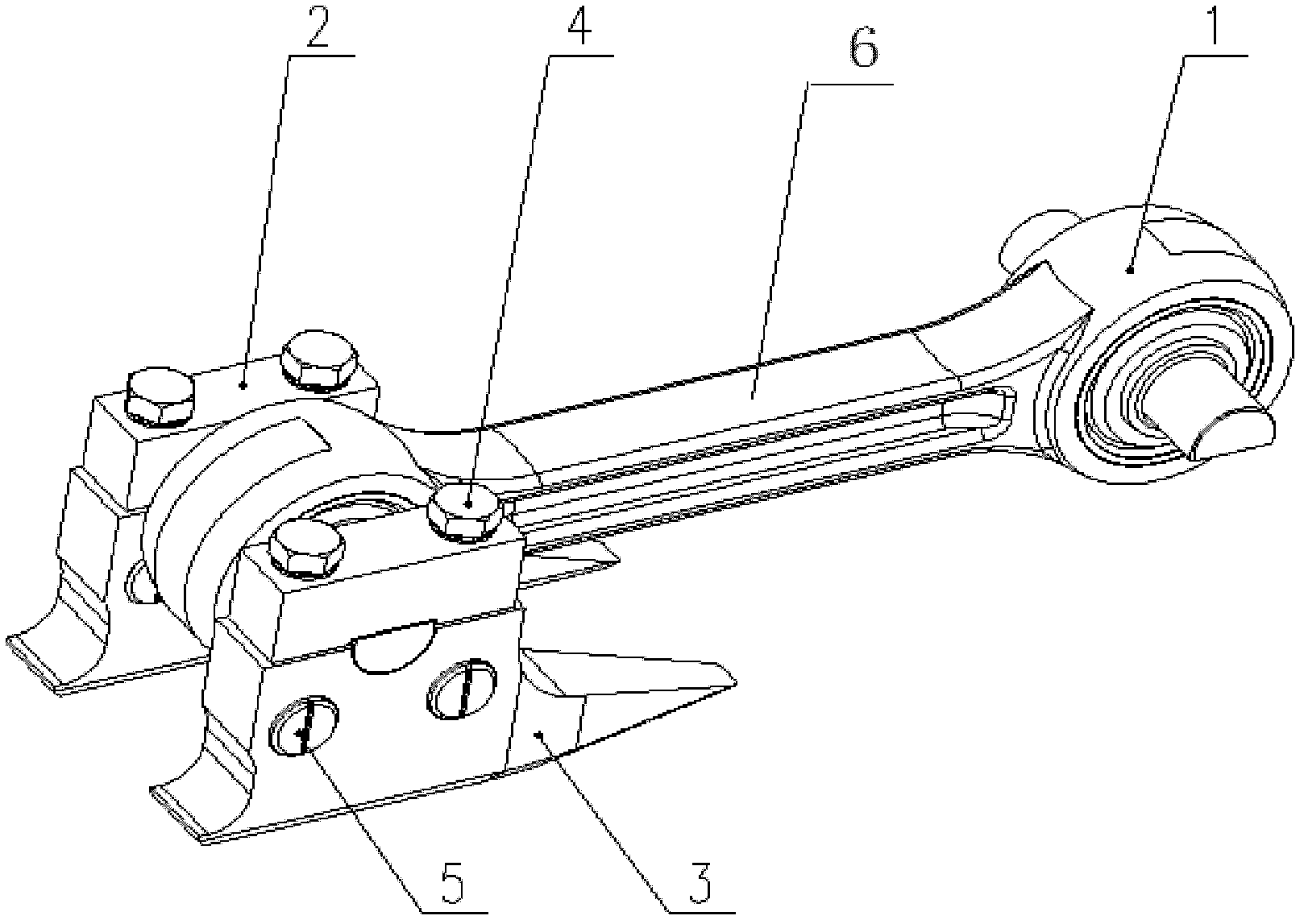

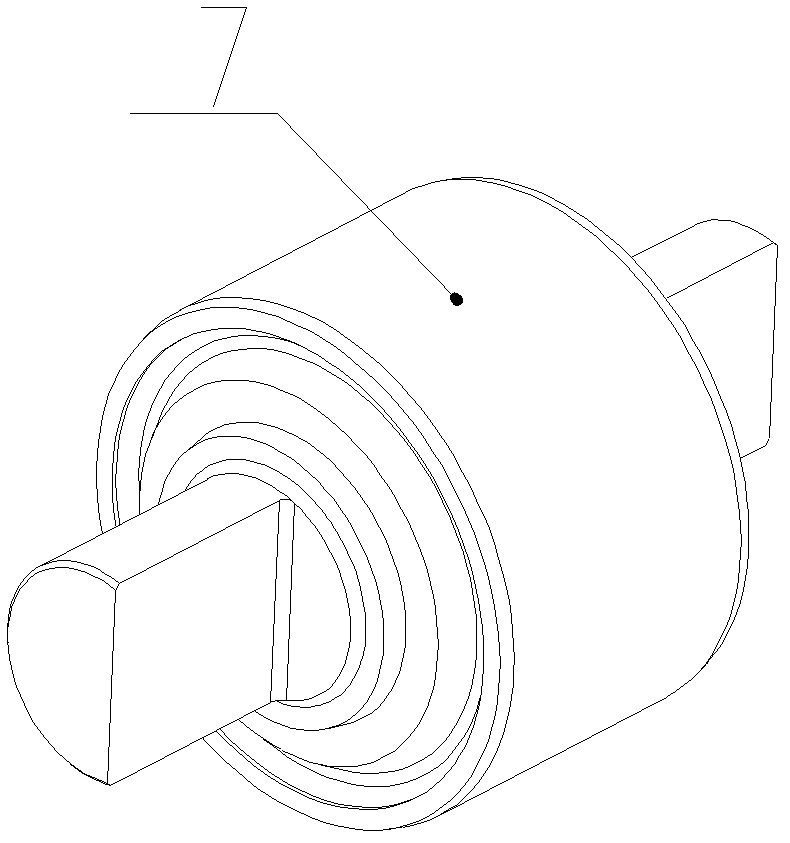

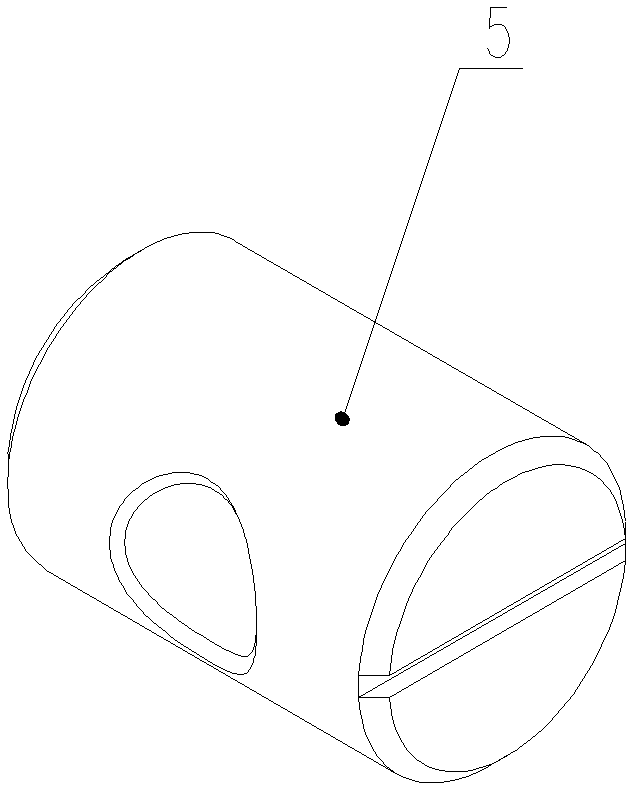

[0021] Traction tie rod devices for railway freight car bogies, such as figure 1 , figure 2 , image 3 As shown, it includes a traction rod assembly 1, an upper mount 2, a lower mount 3, four bolts 4, and four pin nuts 5. The traction rod assembly 1 includes a traction rod 6 and a rubber joint 7. The traction rod The two ends of 6 are circular holes, and the elastic rubber joint 7 is arranged in the circular hole of the traction rod 6, and the rubber joint 7 and the traction rod 6 adopt an interference fit. The traction rod assembly 1 is connected with the holes of the upper mounting base 2 and the lower mounting base 3 through the two ends of the rubber joint 7. The upper mounting base 2 and the lower mounting base 3 are connected by bolts 4 and nuts. The nuts are pin nuts 5 to prevent The upper mounting seat 2 and the lower mounting seat 3 cause e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com