Preparation method of ITQ-13 molecular sieve in non-concentrated-gel system

A molecular sieve and non-condensing technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of increased synthesis cost, poor repeatability, high cost, etc., and achieve the effects of reduced loss, good crystallinity and purity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First, pipette 1.5mL deionized water and 3.0mL TMHDA, mix them well, add 0.104g GeO 2 , 0.20mL tetraethyl orthosilicate (TEOS), add 0.12mL hydrofluoric acid (40wt%) under stirring, continue to stir until a uniform silicon germanium gel is formed, then transfer to a polytetrafluoroethylene reactor, 180 ° C Under the condition of static crystallization for 7 days. The proportion of reaction raw materials is 0.5SiO 2 : 0.5GeO 2 :7TMHDA:42H 2 O: 1.4HF. After the reaction kettle was cooled to room temperature, the product was filtered with suction, washed with water for 4 times, and dried at 85°C to obtain product 1. The BET specific surface area of product 1 measured by nitrogen adsorption is 296.87m 2 / g, the micropore volume is 0.126mL / g, and the pore diameter is

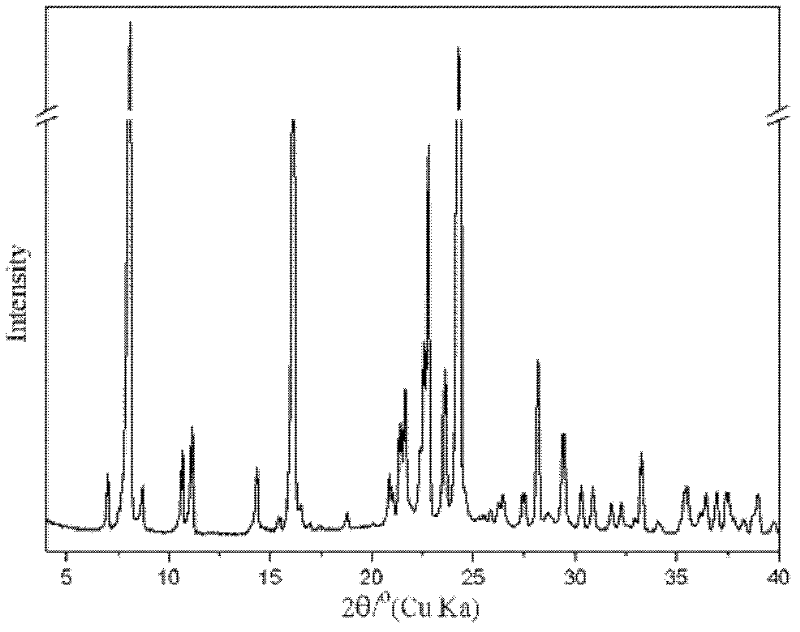

[0035] The XRD spectrum of product 1 is as follows figure 1 . It can be seen that product 1 has a typical ITH molecular sieve structure and has a high degree of crystallinity.

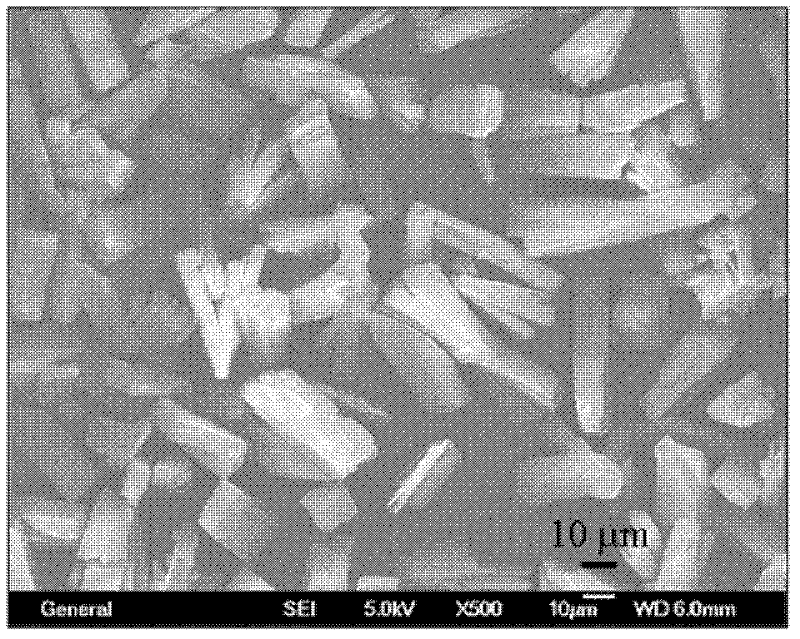

[0036] SEM of produ...

Embodiment 2

[0038] Mix 1.5mL deionized water and 3.0mL TMHDA well, add 0.104g GeO 2 , 0.22mL of silica sol, add 0.12mL of hydrofluoric acid (40wt%) under stirring, continue to stir until a uniform silicon germanium gel is formed, then transfer it to a polytetrafluoroethylene reactor, and statically crystallize at 180°C for 7 sky. The proportion of reaction raw materials is 0.5SiO 2 : 0.5GeO2 :7TMHDA:42H 2 O: 1.4HF. After the reactor was cooled to room temperature, the product was suction filtered, washed with water for 4 times, and dried at 85°C to obtain product 2.

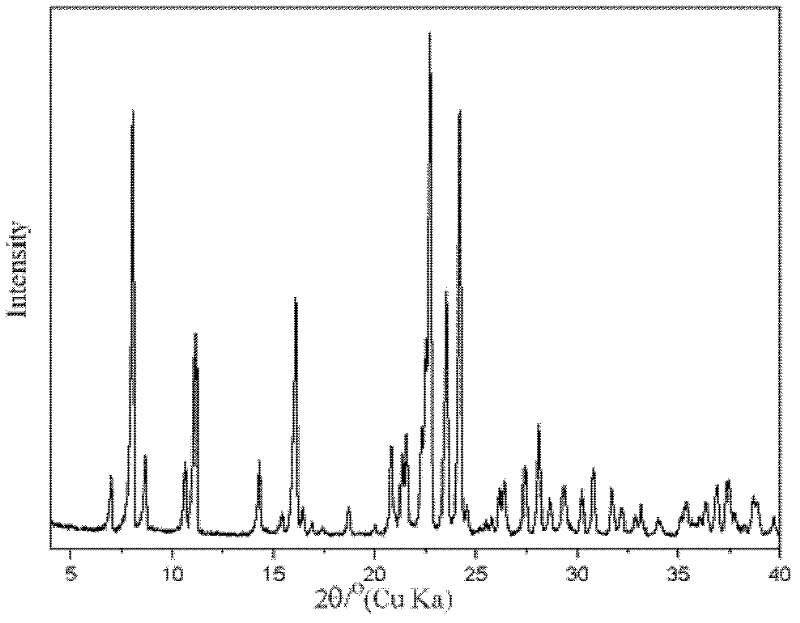

[0039] The XRD spectrum of product 2 is as follows image 3 . The baseline of Product 2 is relatively flat, indicating that Product 2 has a high degree of crystallinity.

[0040] The SEM of Product 2 as Figure 4 . Product 2 has a typical strip crystal morphology with a size of about 20-30 μm.

Embodiment 3

[0042] Measure 1.5mL deionized water and 3.0mL TMHDA, mix well and add 0.104g GeO 2 , 0.20mL TEOS, add 0.15g ammonium fluoride under stirring, continue to stir until a uniform silicon germanium gel is formed, then transfer to a polytetrafluoroethylene reactor, and statically crystallize at 180°C for 7 days. The proportion of reaction raw materials is 0.5SiO 2 : 0.5GeO 2 :7TMHDA:42H 2 O: 1.4NH 4 F. After the reaction kettle was cooled to room temperature, the product was filtered with suction, washed with water for 4 times, and dried at 85°C to obtain product 3.

[0043] The XRD spectrum of product 3 is as follows Figure 5 . The baseline of Product 3 is relatively flat, indicating that Product 3 has a high degree of crystallinity.

[0044] The SEM of product 3 as Image 6 . Product 3 has a bar-shaped crystal morphology, and the size is about 20-30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com