Impregnation device and method of carbon fiber flexible felt prepreg

A dipping device and carbon fiber technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of reducing thermal insulation performance, increasing the gram weight of prepreg, wasting raw materials, etc., to ensure uniformity, improve The effect of dipping speed and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

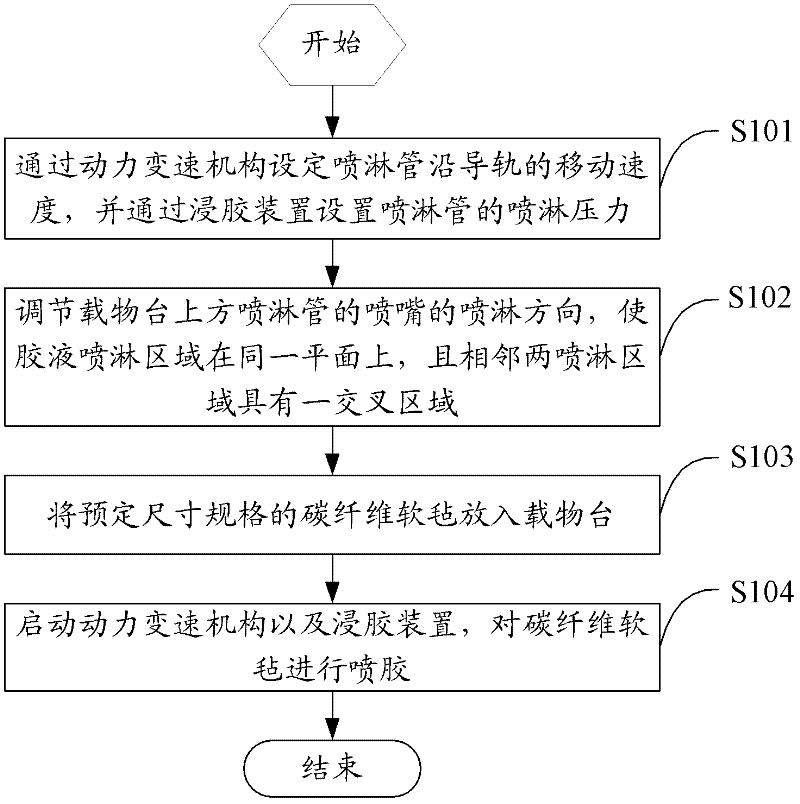

[0026] The solution of the embodiment of the present invention is mainly: by adjusting and setting the moving speed of the spray pipe and the spray pressure, to control the amount of glue impregnation of the carbon fiber felt prepreg, to ensure the uniformity of the glue spray, and to improve the impregnation. Speed and productivity.

[0027] The prepreg mentioned in the present invention refers to the fiber impregnated with the resin system used to make the resin-based composite material.

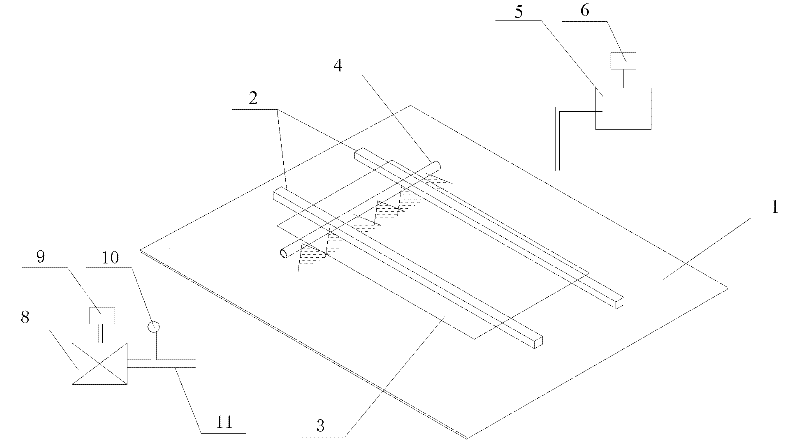

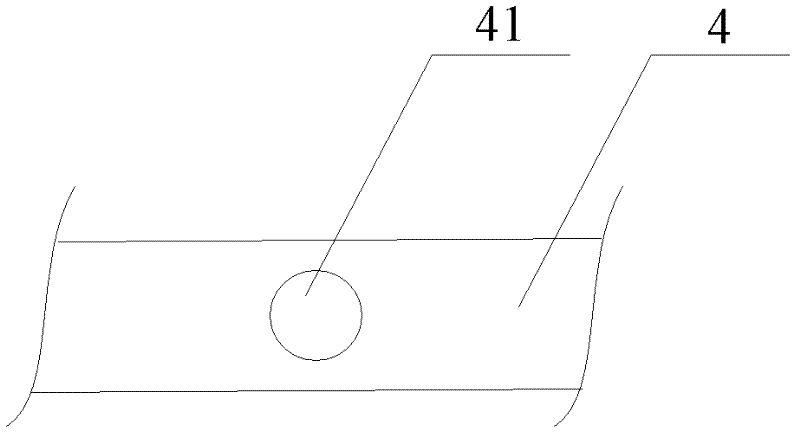

[0028] like figure 1 As shown, the preferred embodiment of the present invention proposes a dipping device for carbon fiber soft felt prepreg, including a stage 1 for carrying carbon fiber soft felt, two parallel guide rails 2, and a The spray pipe 4 for spraying glue, wherein, the number of guide rails 2 can also be set to be multiple according to actual needs.

[0029] In this embodiment, the stage 1 is a movable stage 1, and the stage 1 is supported on a base (not shown in the figur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap