Method for producing aerated building block with phosphogypsum as main raw material

An air-entrained block and phosphogypsum technology is applied in the fields of comprehensive utilization of resources and new building materials to achieve the effects of reducing secondary pollution and high cost problems, saving natural resources and using large amounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

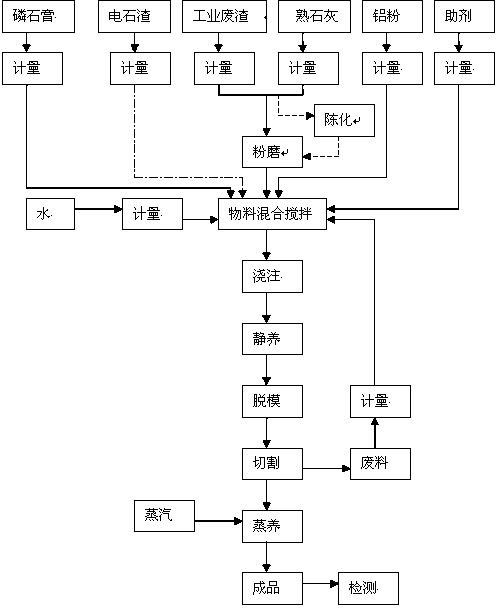

Image

Examples

Embodiment 1

[0035] Embodiment 1: This is the method for producing aerated block with phosphogypsum as the main raw material, the specific content is as follows:

[0036] 1, the raw material composition is as follows in this method:

[0037] (1) Main materials: phosphogypsum 21kg, blast furnace slag 7.5kg, hydrated lime 1.5kg;

[0038] (2) Process water is alkali-containing wastewater from paper mills, and the mass ratio of water to main materials is 1:0.85;

[0039] (3) Mineral stimulant additional components: sodium sulfate and sodium chloride are 1.2% of the mass of slaked lime, and the mass ratio of sodium sulfate to sodium oxide is 1:1;

[0040] (4) Auxiliary raw materials: 0.05% of aluminum powder as the main material; 0.5% of additives as the main material, including 70 parts of water glass, 25 parts of sodium hydroxide, and 5 parts of sodium lignosulfonate.

[0041] 2, the concrete operation of the present invention is as follows:

[0042] Mix and age 7.5kg of blast furnace slag...

Embodiment 2

[0044] Embodiment 2: This is the method for producing aerated block with phosphogypsum as the main raw material, the specific content is as follows:

[0045] 1, the raw material composition is as follows in this method:

[0046] (1) Main materials: phosphogypsum 18kg, yellow phosphorus slag 6kg, activated iron tailings 2.4kg, carbide slag (dry basis) 3.6kg;

[0047] (2) The process water is recycled reclaimed water, and the mass ratio of water to main material is 1:0.95(m / m);

[0048] (3) Additional components of mineral activator: sodium sulfate and sodium oxide are 0.5% of the mass of carbide slag, and the mass ratio of sodium sulfate and sodium oxide is 1:0.5;

[0049] (4) Auxiliary raw materials: 0.04% of aluminum powder as the main raw material; 0.3% of additives as the main raw material, including 70 parts of water glass, 25 parts of sodium hydroxide, and 5 parts of calcium lignosulfonate.

[0050] 2, the concrete operation of the present invention is as follows:

[0...

Embodiment 3

[0053] Embodiment 3: this is the method for producing aerated block with phosphogypsum as the main raw material, the specific content is as follows:

[0054] 1, the raw material composition is as follows in this method:

[0055] (1) Main materials: phosphogypsum 19.5kg, yellow phosphorus slag 4.5kg, fly ash 4.0kg, slaked lime 2.0kg;

[0056] (2) The process water is condensed water, and the mass ratio of water to main material is 1:0.9;

[0057] (3) Mineral activator additional components: sodium sulfate and sodium oxide are 0.4% of slaked lime, and the ratio of sodium sulfate to sodium oxide is 1:0.8;

[0058] (4) Auxiliary raw materials: aluminum powder is 0.05% of the main raw material; additives are 0.4% of the main raw material, including 60 parts of water glass, 25 parts of sodium hydroxide, 10 parts of calcium lignosulfonate, lignosulfonic acid Sodium 5 parts.

[0059] 2, the concrete operation of the present invention is as follows:

[0060] Mix and age 4.5kg of ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com