Silicon modified lignin intumescent flame-retardant charring agent and preparation method and application thereof

An intumescent flame retardant and lignin technology, which is applied in the application field of carbon source in polylactic acid matrix, can solve the problems of insufficient flame retardant efficiency, poor compatibility, easy migration, etc., achieve good flame retardant effect and improve stability , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

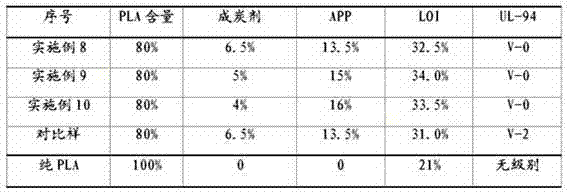

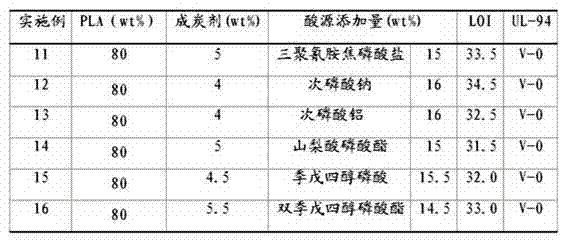

Examples

Embodiment 1

[0028] Add 50ml of deionized water and 150ml of ethanol to a reaction kettle equipped with a stirring and reflux device. After stirring evenly, add 40g of lignin and 1g of OP-10, heat to 30°C while stirring, and add hydrochloric acid solution to adjust the pH value to 2- 4. Slowly add 5g of organosilicon oxide compound dropwise at a rate of 2ml / min, stir for 3.5 hours, then lower the reaction kettle to room temperature, filter, wash, and dry the filter cake at 100°C and 30mmHg to obtain a powder 42.1g of char-forming agent product.

Embodiment 2

[0030] Add 50ml of deionized water and 150ml of ethanol to a reaction kettle equipped with a stirring and reflux device. After stirring evenly, add 50g of lignin and 1g of OP-10, heat to 30°C while stirring, and add hydrochloric acid solution to adjust the pH to 2- 4. Slowly add 7.5g organosiloxane compound dropwise at a rate of 4ml / min, stir for 4.5 hours, then lower the reaction kettle to room temperature, filter, wash, and dry the filter cake at 110°C and 30mmHg to obtain a powder 52.3 g of char-forming agent product.

Embodiment 3

[0032] Add 50ml of deionized water and 150ml of ethanol to a reaction kettle equipped with a stirring and reflux device. After stirring evenly, add 50g of lignin and 1g of OP-10, heat to 30°C while stirring, and add hydrochloric acid solution to adjust the pH to 2- 4. Slowly add 10g of organosilicon oxide compound dropwise at a rate of 4ml / min, stir for 5 hours, then lower the reaction kettle to room temperature, filter, wash, and dry the filter cake at 110°C and 30mmHg to obtain a powder 53.3g of char-forming agent product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com