Semi energy storage type electromechanical brake and automobile

An electromechanical braking and energy storage technology, which is applied in the direction of brake types, axial brakes, mechanical equipment, etc., can solve the problems that the electromechanical braking system cannot be applied and promoted, and achieves compact structure and adjustable braking clearance. The effect of adjusting and shortening the response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

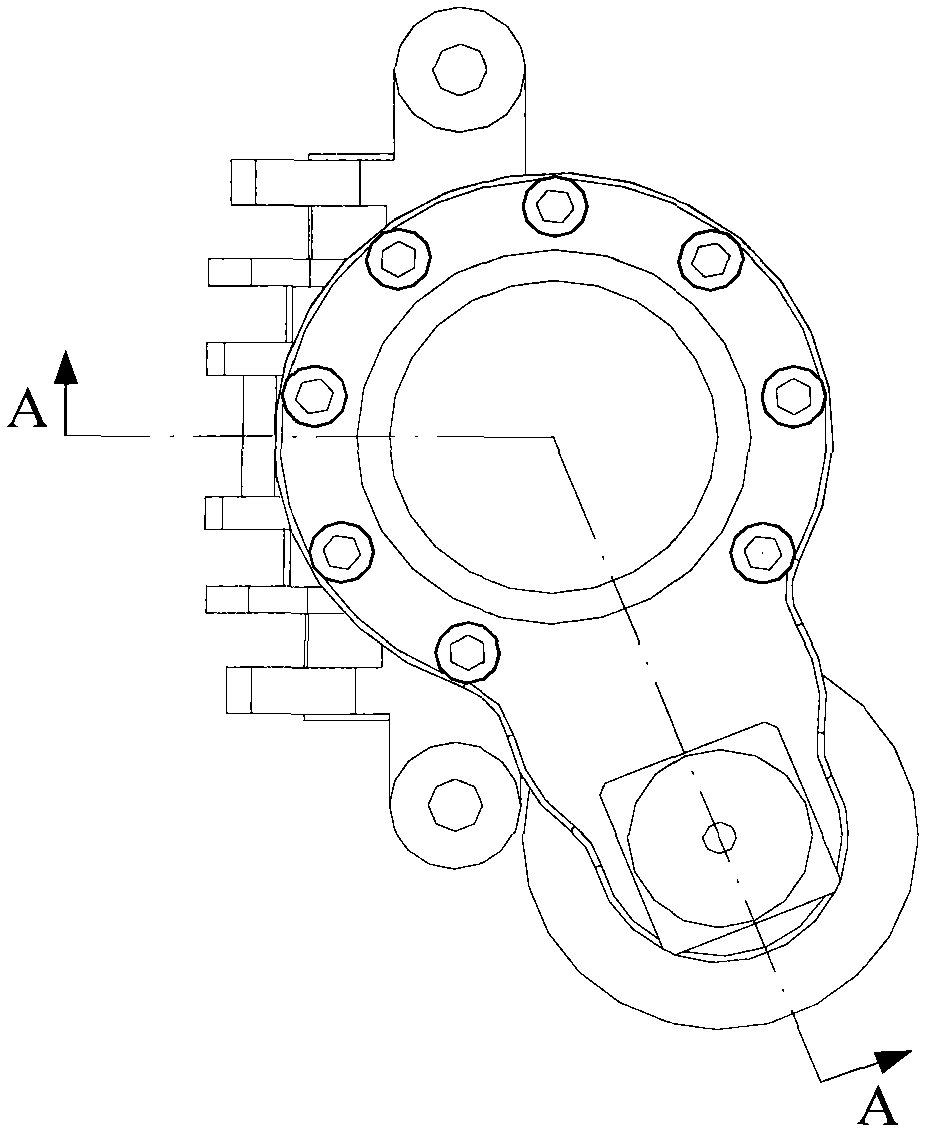

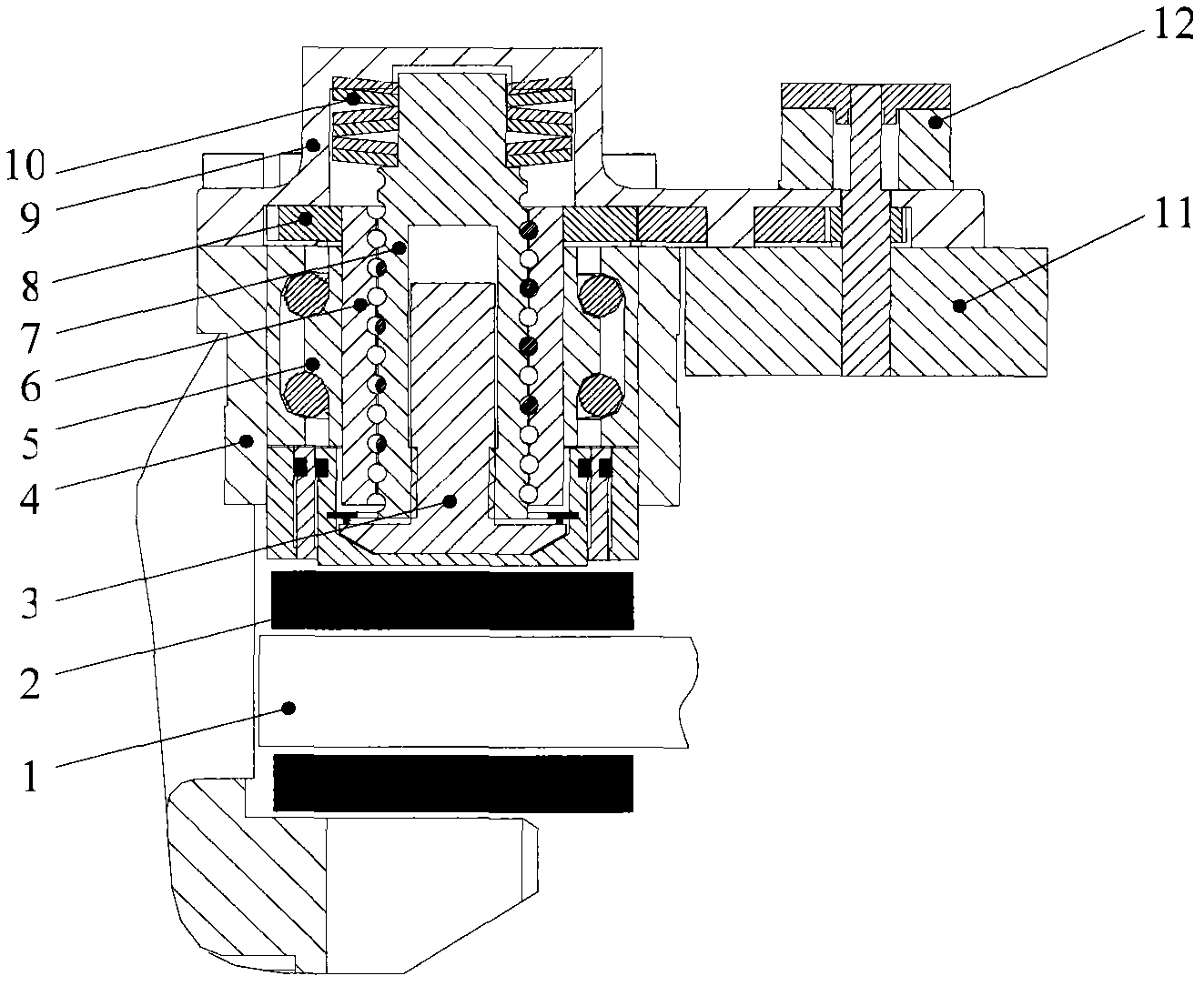

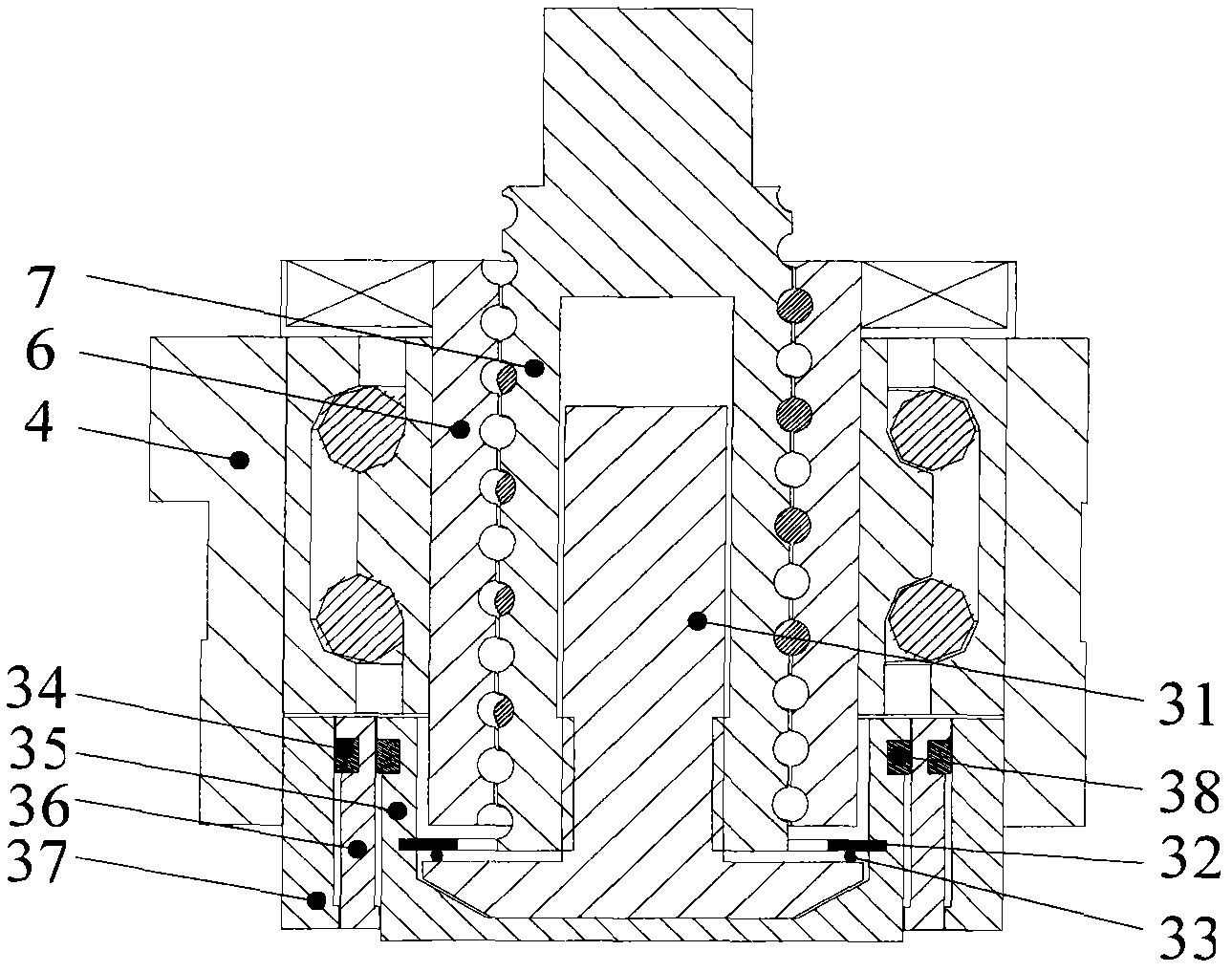

[0035] Such as figure 1 , 2 As shown, in this embodiment, the semi-energy storage electromechanical brake includes a housing 9, a brake caliper body 4, a brake disc 1, and a friction plate 2, which can push the friction plate 2 forward to clamp the brake disc 1, and a gap self-adjusting mechanism 3 that can automatically adjust the braking gap between the moving mechanism and the friction plate 2.

[0036] The power mechanism includes a motor 11, an electromagnetic clutch 12, a torque amplification mechanism, a motion mechanism for converting the rotational motion of the motor 11 into a linear motion, and an elastic mechanism.

[0037] In this embodiment, the torque amplification mechanism adopts a reduction mechanism 8, and the reduction mechanism 8 includes a pinion gear set on the output shaft of the motor 11, an intermediate gear meshing with the pinion gear, and an output gear meshing with the intermediate gear . The output gear is fixed on the input end of the motion ...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that this embodiment does not have the gap self-adjusting mechanism 3 in Embodiment 1. Wherein, the front end of the lead screw 7 can directly contact the friction plate 2, and the brake can be realized by eliminating the gap between the brake disc 1 and the friction plate 2.

[0058] Other structures and uses in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0060] The difference between this embodiment and Embodiment 1 is that this embodiment does not have the elastic mechanism in Embodiment 1.

[0061] Other structures and uses in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com