Backlight module without light guide plate and LCD (liquid crystal display) device

A technology of backlight module and no light guide plate, which is applied in the direction of lighting devices, fixed lighting devices, parts of lighting devices, etc., which can solve the problem of unreasonable setting of light sources and reflectors, low light utilization rate, and uneven uniformity. Too good and other problems, to achieve the effect of weight reduction, light guide plate reduction, and improvement of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

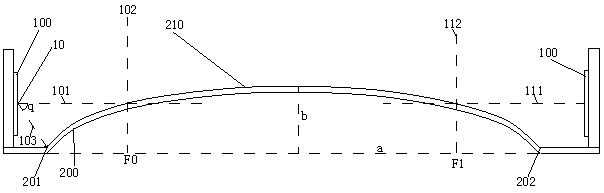

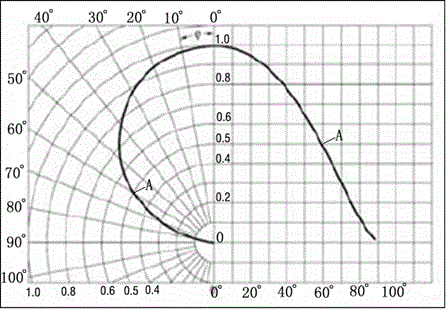

[0021] The backlight module and LCD device without light guide plate provided by the present invention achieve the effect of uniform distribution of light intensity mainly by specially designing the slope of the reflective curved surface in the optical system, which is the purpose and technical solution of the present invention. And the advantages are more clear and definite, the following further describes the present invention in detail with reference to the drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

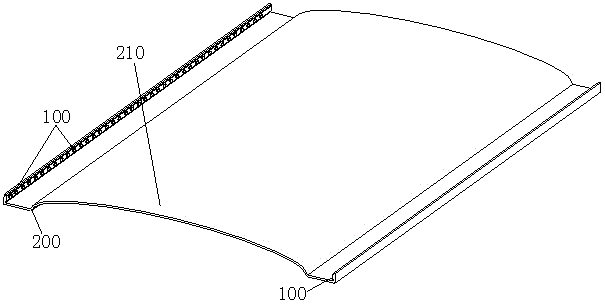

[0022] An embodiment of the present invention provides a backlight module without a light guide plate, such as figure 1 As shown, it includes a light source 100 and a back plate 200. Both sides of the back plate 200 are bent upward to form side walls respectively. The light source 100 is fixed on the side walls on both sides of the back plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com