Dynamic simulation analytical method for locking device of rail traffic vehicle door system

A rail transit vehicle and dynamics simulation technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to effectively improve the performance of door system locking devices, long development cycles, and high risks. Achieve the effects of shortening the development cycle, improving optimization, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] Example 1

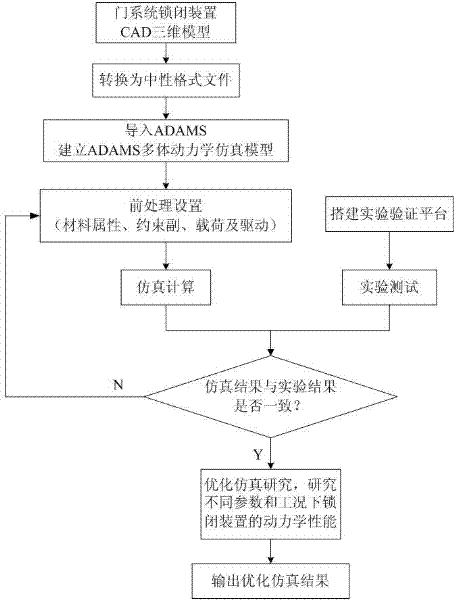

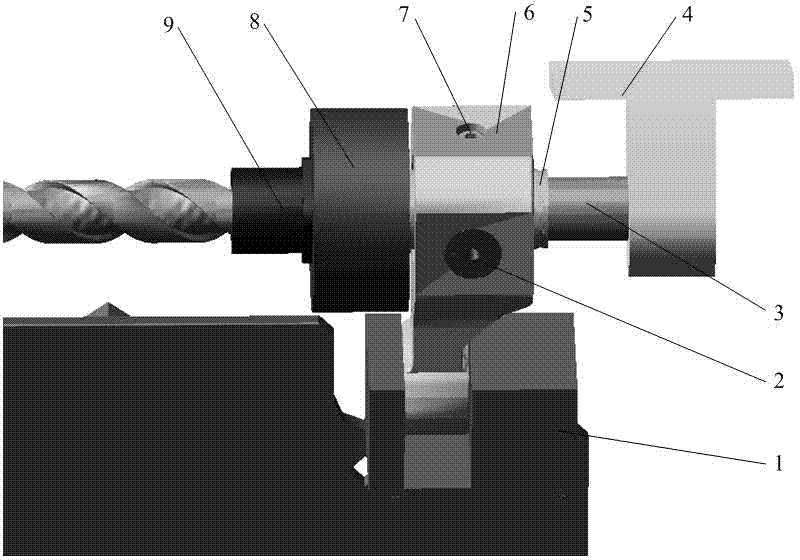

[0055] In this embodiment, the door opening process of the door system is taken as an example to illustrate the simulation process of the present invention.

[0056] In the ADAMS simulation environment, the external load is set to 75N resistance, which acts horizontally on the door panel 1 (opposite to its movement direction), the motor drive parameter is 205r / min (forward rotation), and the contact parameter setting of the rolling lock pin 2 is shown in Table 1.

[0057] Table 1 Contact parameters of rolling lock pin 2

[0058] parameter name Settings Stiffness1e8 Non-linear index of force1.5 Maximum viscous damping coefficient5e4 Maximum deformation depth1e-4 Static drag coefficient0.5 Sliding speed of static resistance1e-4 Dynamic drag coefficient0.2 Dynamic resistance transfer speed1e-2

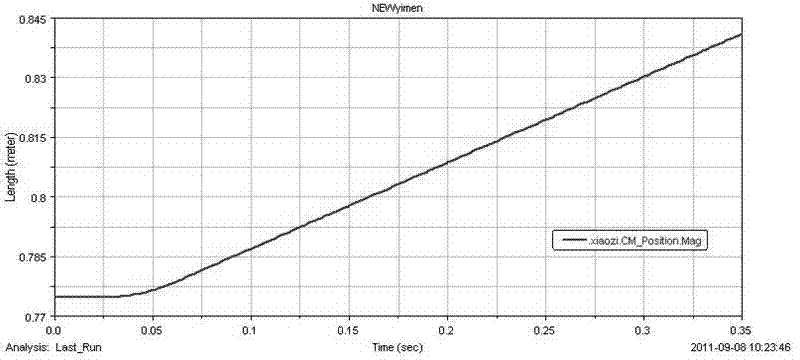

[0059] Under the above parameter settings, the simulation results of the displacement, velocity, acceleration and force of the rolling lock pin 2 are as follows Fi...

Example Embodiment

[0061] Example 2

[0062] In this embodiment, the door closing process of the door system is taken as an example to illustrate the simulation process of the present invention.

[0063] In the ADAMS simulation environment, set the external load, motor drive parameters, and the contact parameters of the rolling lock pin 2. Among them, the external load and the contact parameters of the rolling lock pin 2 are the same as those set in Embodiment 1, and the motor driving parameter is 50 r / min (reverse rotation). Under the above parameter settings, the simulation results of the displacement, velocity, acceleration and force of the rolling lock pin 2 are as follows Figure 7 ~ Figure 10 Shown. From Figure 7 ~ Figure 10 In the door system closing process, the locking device, especially the movement and force of the lock pin 2 can be deeply understood, and a conclusion similar to the above-mentioned door opening process can be drawn from this: that is, the rolling lock pin 2 and the sc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap