Cutting apparatus

A cutting device and cutting fluid technology, applied in the direction of fine working devices, electrical components, working accessories, etc., can solve the problem of insufficient fluidity of cutting fluid, and achieve the effects of good fluidity, reduction of gaps, and inhibition of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Next, preferred embodiments of the cutting device according to the present invention will be described in further detail with reference to the drawings.

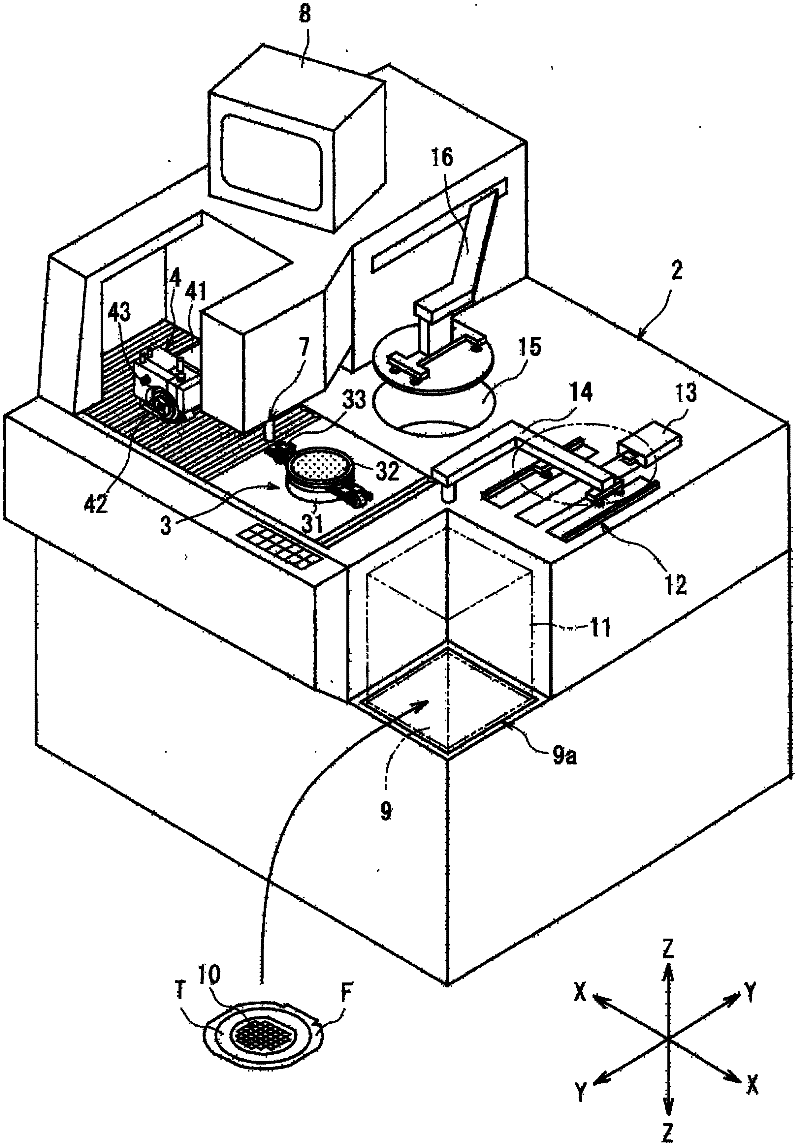

[0045] figure 1 A perspective view of a cutting device constructed by the present invention is shown. figure 1 The shown cutting device includes a substantially cuboid-shaped device housing 2 . In the device case 2, a chuck table 3 holding a workpiece is disposed so as to be movable in a direction indicated by an arrow X (X-axis direction) which is a cutting feed direction. The chuck table 3 includes a suction chuck support table 31 and a suction chuck 32 disposed on the suction chuck support table 31, and the workpiece is sucked and held on the suction chuck by operating a suction member (not shown). The upper surface of 32 promptly keeps on the face. In addition, the chuck table 3 is configured to be rotatable by a rotation mechanism not shown. In addition, a clamper 33 for fixing a ring-shaped frame supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com