Method for preparing high-magnetic energy product samarium-cobalt-based permanent magnet by modifying hydrogenated samarium nano powder

A technology of high energy product and nanopowder, which is applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of magnet remanence and energy product improvement space, magnet coercive force decrease, etc., to achieve Wider use range, improved remanence, wide range of application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

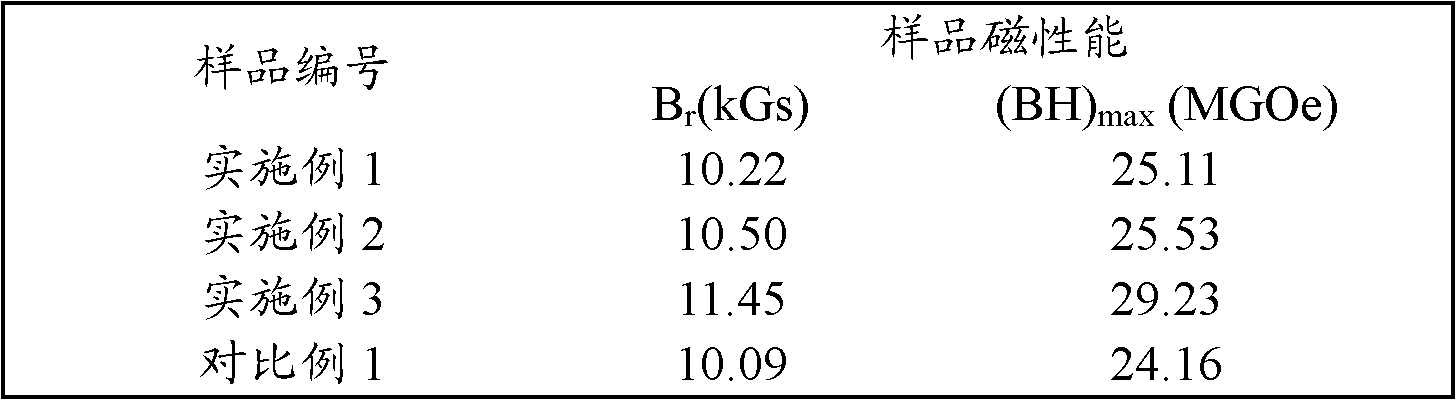

Embodiment 1

[0018] SmCoCuFeZr alloy ingots were prepared by intermediate frequency induction melting technology, and the composition was Sm: 25.4wt.%; Co: 58.0wt.%; Fe: 5.5wt.%; Cu: 7.8wt%; Zr: 3.3wt.%, and then Crushed into a powder with an average particle size of 3 microns. Afterwards, samarium hydride nanopowder accounting for 1% by weight of the SmCoCuFeZr micron powder and having an average particle size of 20 nanometers was doped into the above-mentioned initial powder, and the two were evenly mixed. The mixed powder was compacted in a magnetic field of 2T, and then subjected to isostatic pressing at a pressure of 200 MPa to obtain a green compact. Put the compact into a vacuum sintering furnace, pre-sinter the sample at 1190°C for 30 minutes in vacuum, then sinter at 1220°C under argon protection for 90 minutes, then undergo solution treatment at 1180°C for 210 minutes, and then air cool to room temperature; Carry out solution aging treatment, first keep warm at 840°C for 12h, th...

Embodiment 2

[0020] SmCoCuFeZr alloy ingots were prepared by intermediate frequency induction melting technology, and the composition was Sm: 26.4wt.%; Co: 57.0wt.%; Fe: 5.5wt.%; Cu: 7.8wt%; Zr: 3.3wt.%, and then Crushed into a powder with an average particle size of 4 microns. Afterwards, samarium hydride nanopowder accounting for 2% by weight of the SmCoCuFeZr micron powder and having an average particle size of 50 nanometers was doped into the above-mentioned initial powder, and the two were mixed evenly. The mixed powder was compacted in a magnetic field of 2T, and then subjected to isostatic pressing at a pressure of 200 MPa to obtain a green compact. Then put the compact into a vacuum sintering furnace, pre-sinter the sample in vacuum at 1190°C for 30 minutes, then sinter at 1225°C under argon protection for 90 minutes, then undergo solution treatment at 1185°C for 210 minutes, and then air cool to room temperature; Afterwards, solid solution aging treatment is carried out, first at...

Embodiment 3

[0022] SmCoCuFeZr alloy ingots were prepared by medium frequency induction melting technology, and the composition was Sm: 26.0wt.%; Co: 57.4wt.%; Fe: 5.5wt.%; Cu: 7.8wt%; Zr: 3.3wt.%, and then Crushed into a powder with an average particle size of 5 microns. Afterwards, 3% by weight of the SmCoCuFeZr micron powder is doped with samarium hydride nanopowder with an average particle size of 100 nanometers into the above initial powder, and the two are mixed evenly. The mixed powder was compacted in a magnetic field of 2T, and then subjected to isostatic pressing at a pressure of 200 MPa to obtain a green compact. Then put the compact into a vacuum sintering furnace, pre-sinter the sample in vacuum at 1190°C for 30 minutes, then sinter at 1230°C under argon protection for 90 minutes, and then undergo solution treatment at 1190°C for 210 minutes, and then air-cool to room temperature; Afterwards, solid solution aging treatment is carried out, first at 840°C for 12h, then cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com