Manufacturing method for producing single face stainless steel composite plate by adopting hot continuous rolling set

A manufacturing method and stainless steel technology, applied in metal rolling, manufacturing tools, metal rolling and other directions, can solve the problems of complex production process flow, affecting the normal bite of the rolling mill, and difficulty in hot rolling production, and achieve a short production process flow. , Excellent comprehensive mechanical properties, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A method for producing a single-sided stainless steel clad plate by a hot continuous rolling mill, the specific process flow is as follows:

[0015] (1) Stainless steel and ordinary carbon steel are prepared by composite method to prepare single-sided stainless steel composite slab;

[0016] (2) The composite slab is heated by the high-temperature rapid firing method, the heating temperature is controlled at 1180-1280°C, the soaking time is 15-60min, and the temperature difference between the substrate and the cladding plate surface is controlled at 5-30°C by adjusting the furnace gas temperature;

[0017] (3) Adjust the roll speed ratio of the rough rolling work rolls to 1.04~1.3 to control the shape of the intermediate slab and avoid serious "head warping" and "buckling" phenomena due to the difference in elongation coefficient of the cladding layer and the base material;

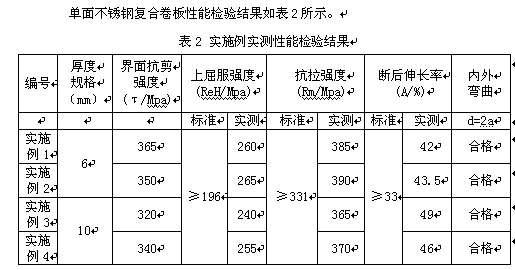

[0018] (4) The finish rolling temperature is 830-920°C, the cooling rate after rolling is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com