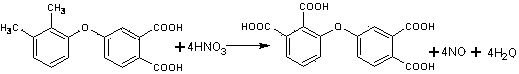

Method for synthesizing 2,3,3',4'-diphenyl ether tetracarboxylic acid

A technology for the synthesis of dimethyl diphenyl ether dicarboxylic acid, which is applied in the preparation of carboxylic acid salts, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of low concentration, complicated operation, and high cost, and achieve the goal of reaction Mild conditions, high product purity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Taking the high-pressure valve as an example, add the dimethyl diphenyl ether dicarboxylic acid and 40% dilute nitric acid (the dimethyl diphenyl ether dicarboxylic acid and HNO 3 The molar ratio is preferably 1:4.4), close the lid of the kettle, stir and heat. Observe the experimental phenomena and record the changes of process parameters such as pressure and temperature.

[0030] As the temperature rises, the pressure of the system increases. When the temperature reaches 120~150°C, the reaction is initiated. The pressure is controlled at 1~3MPa, and the reaction is carried out at 120~150°C for 1~2 hours.

[0031] Then raise the temperature to 180~220℃, continue to control the pressure at 1~3MPa, and react for 0.5~2 hours.

[0032] After the reaction is completed, cool down to below 80°C, and slowly release the pressure to normal pressure. The reaction product was poured out and cooled naturally or placed in ice water for 6-12 hours, and crystallization appeared.

...

Embodiment 2

[0035] In the autoclave, add the dimethyl diphenyl ether dicarboxylic acid and 30% dilute nitric acid (the dimethyl diphenyl ether dicarboxylic acid and HNO 3 The molar ratio is preferably 1:6), close the lid of the kettle, stir and heat. Observe the experimental phenomena and record the changes of process parameters such as pressure and temperature.

[0036] As the temperature rises, the pressure of the system increases. When the temperature reaches 120~150°C, the reaction is initiated. The pressure is controlled at 1~3MPa, and the reaction is carried out at 120~150°C for 1~2 hours.

[0037] Then raise the temperature to 180~220℃, continue to control the pressure at 1~3MPa, and react for 0.5~2 hours.

[0038] After the reaction was completed, the temperature was cooled, and the pressure was slowly released to normal pressure. The reaction product was poured out and cooled naturally or placed in ice water for 6-12 hours, and crystallization appeared.

[0039] After filterin...

Embodiment 3

[0041] In the autoclave, add the dimethyl diphenyl ether dicarboxylic acid and 20% dilute nitric acid (the dimethyl diphenyl ether dicarboxylic acid and HNO 3 The molar ratio is preferably 1:8), close the lid of the kettle, stir and heat. Observe the experimental phenomena and record the changes of process parameters such as pressure and temperature.

[0042] As the temperature rises, the pressure of the system increases. When the temperature reaches 120~150°C, the reaction is initiated. The pressure is controlled at 1~3MPa, and the reaction is carried out at 120~150°C for 1~2 hours.

[0043] Then raise the temperature to 180~220℃, continue to control the pressure at 1~3MPa, and react for 0.5~2 hours.

[0044] After the reaction was completed, the temperature was cooled, and the pressure was slowly released to normal pressure. The reaction product was poured out and cooled naturally or placed in ice water for 6-12 hours, and crystallization appeared.

[0045] After filterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com