Silicon carbide semiconductor device and manufacturing method of the same

A manufacturing method and technology of silicon carbide, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficulty in forming trench sidewalls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

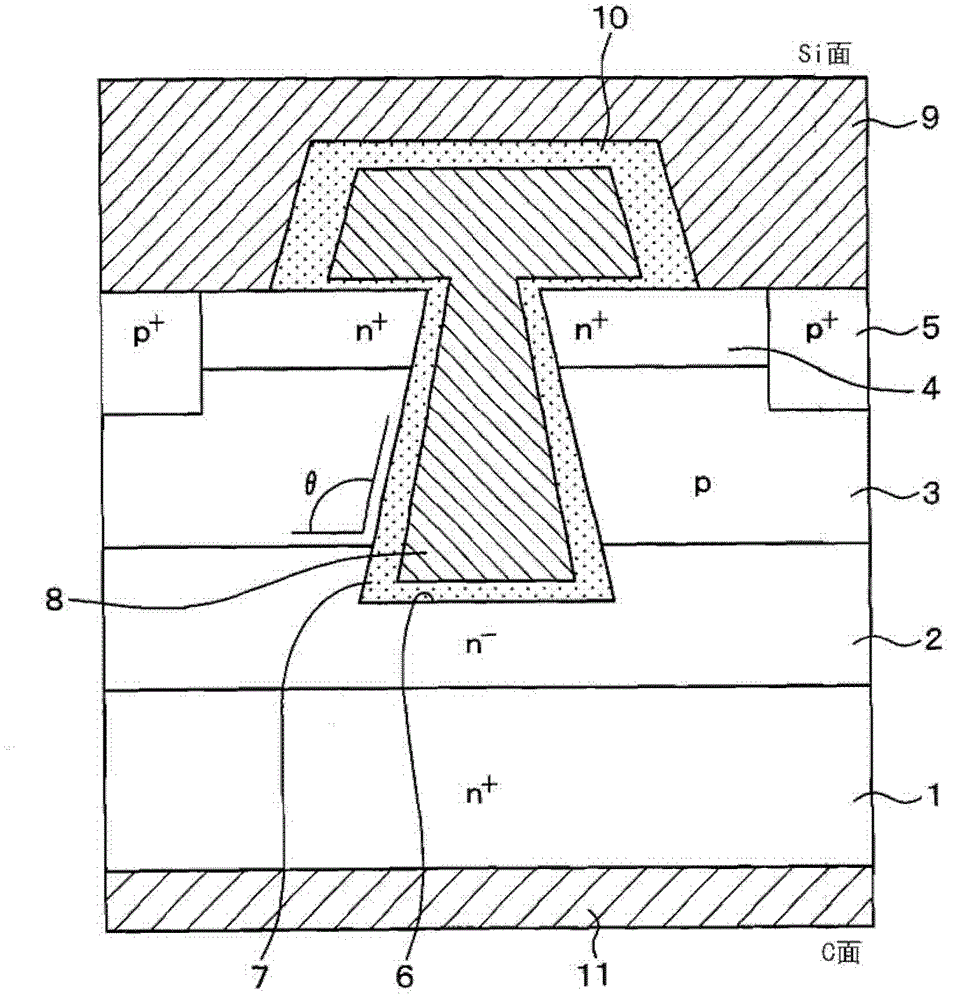

[0022] will refer to figure 1 A SiC semiconductor device according to a first embodiment of the present disclosure is described. SiC semiconductor devices include vertical MOSFETs with trench gate structures. In this embodiment, for example, the first conductivity type is set as n-type, and the second conductivity type is set as p-type.

[0023] like figure 1 shown, using SiC made n + type substrate 1 to fabricate vertical MOSFETs. no + The substrate 1 has a Si plane as a main surface, which is a (0001) Si plane. no + Type substrate 1 is doped with a concentration of, for example, 1.0×10 19 / cm 3 n-type impurity, such as phosphorus, and has a thickness of about 300 μm. in n + type substrate 1 is formed on the surface of SiC made of n - Type drift layer 2. no - Type drift layer 2 is doped with a concentration of, for example, 5.0×10 15 / cm 3 to 2.0×10 16 / cm 3 n-type impurity, such as phosphorus, and has a thickness of about 8 μm to 15 μm. in n - A p-type bas...

no. 2 example

[0046] A SiC semiconductor device according to a second embodiment of the present disclosure will be described. Since in this embodiment, the shape of the groove 6 is changed from that of the first embodiment and otherwise similar to the first embodiment, only the different parts will be described.

[0047] like Figure 4 As shown, in this embodiment, the corners of the bottom of the trench 6 are rounded. The SiC semiconductor device according to this embodiment can basically be manufactured using the manufacturing method described in the first embodiment. allowable Figure 3A In the manufacturing process shown, the rounding of the bottom corners of the trench 6 is performed by controlling the etching conditions during the formation of the trench 6 , or by performing sacrificial oxidation and heat treatment after the formation of the trench 6 .

[0048] In the SiC semiconductor device according to the present embodiment, when the sidewall of the p-type base region 3 forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com