Liquid-spraying device and glass-cleaning robot with liquid-spraying device

A technology of a liquid spray device and a robot body, which is applied to distribution devices, packaging, window cleaning, etc., can solve the problems of robot pollution, circuit board short circuit, and complicated spraying process of cleaning liquid, etc., to achieve high spray efficiency and avoid pollution. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

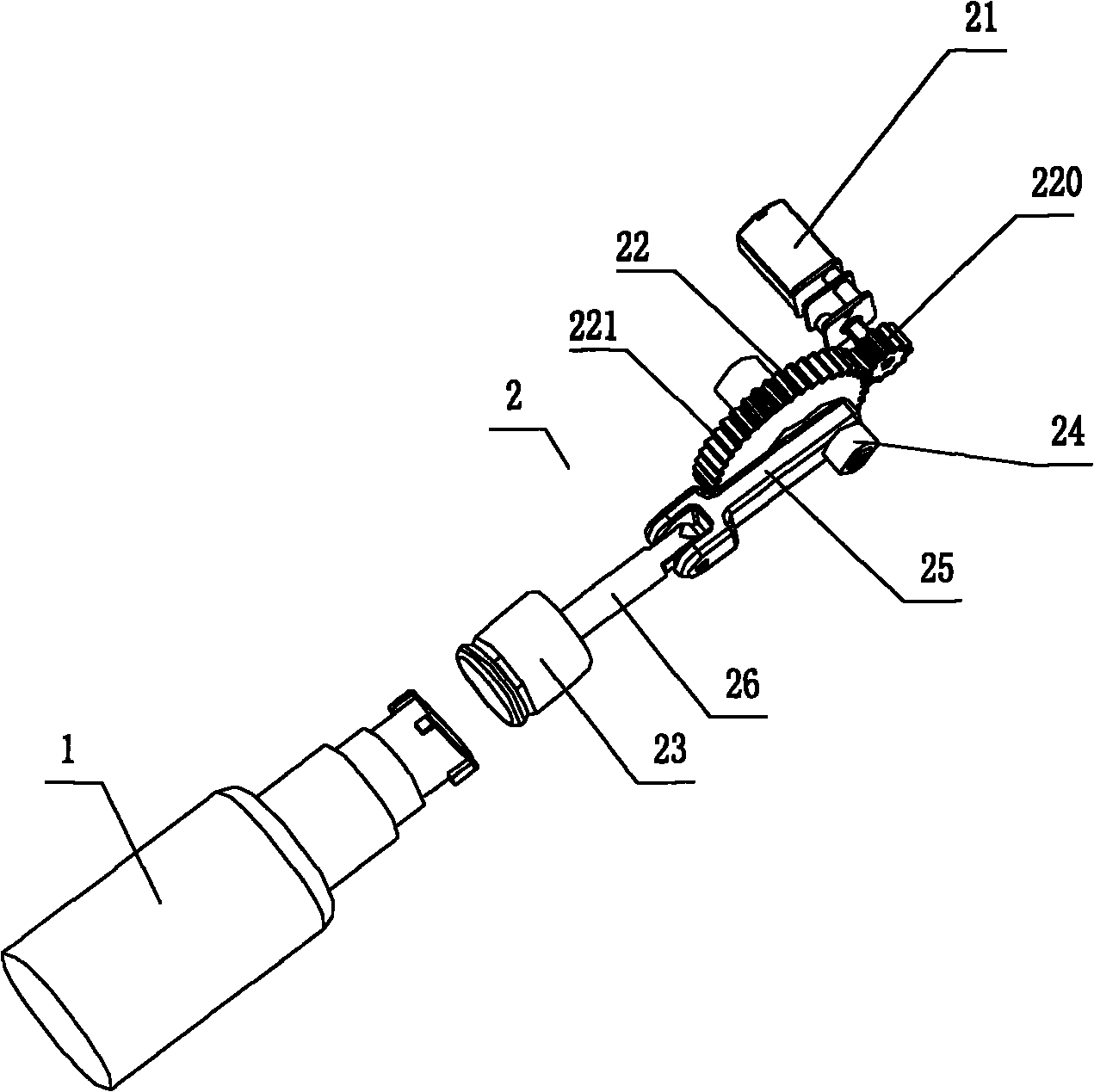

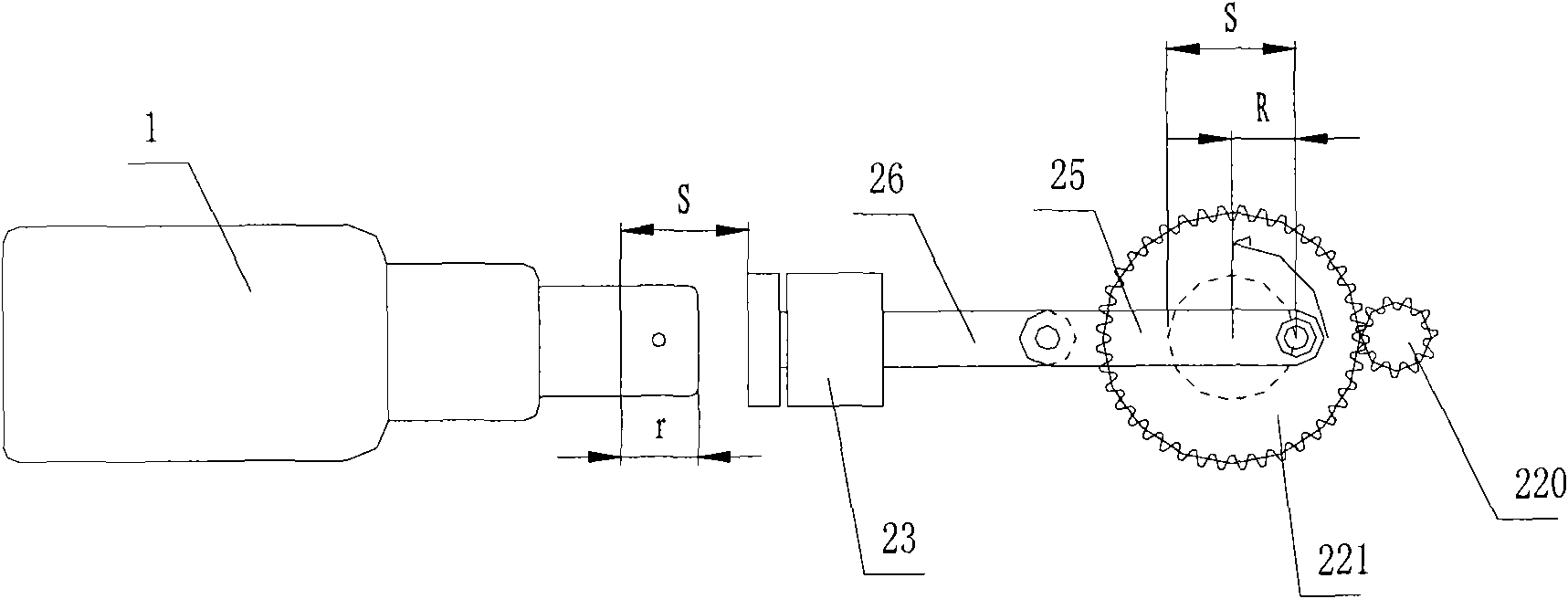

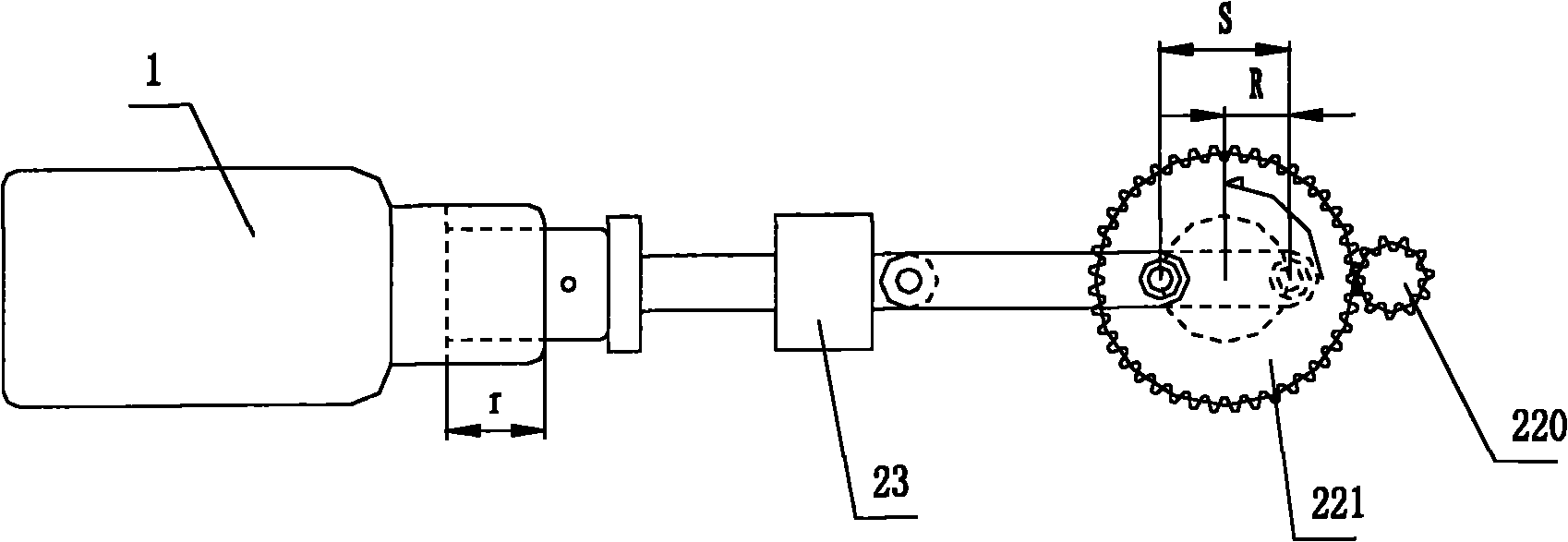

[0017] figure 1 It is a schematic diagram of the overall structure of the liquid spraying device of the present invention. Such as figure 1 As shown, the present invention provides a liquid spraying device, including a solution bottle 1 and an automatic pushing mechanism 2, wherein the automatic pushing mechanism 2 includes a driving motor 21, and the output shaft of the driving motor 21 is connected with a rotating part 22, in order to obtain Appropriate rotating speed, on the output shaft of drive motor 21, be provided with pinion 220, be provided with reduction gear 221 on rotating part 22, reduction gear 221 is meshed with pinion 220, and one end of fork 25 is hinged on the rotating body 22. On one side of the wheel body, the other end is hinged to one end of the push rod 26, and the free end on the other side of the push rod 26 is set correspondingly to the pressing end of the solution bottle 1; The distance is R, and the pressing stroke of the solution bottle 1 is r, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com