Welding device for straight seam single-side welding and double-side forming of conical steel pipes

A welding device, single-sided welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of wasting manpower and welding materials, affecting the health of employees, affecting the quality of welding seams, etc., to avoid physical injury, Simple structure and the effect of improving weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

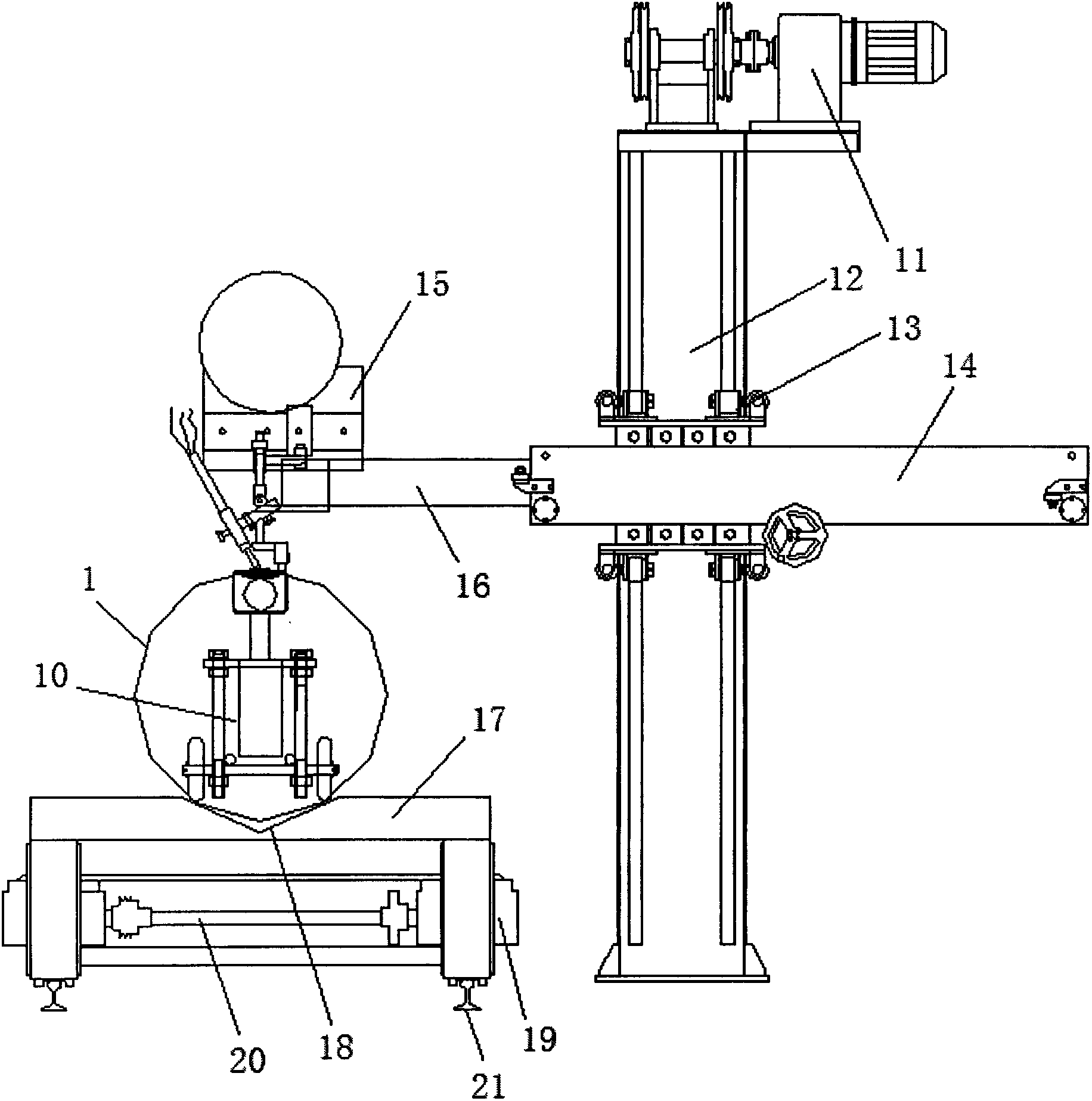

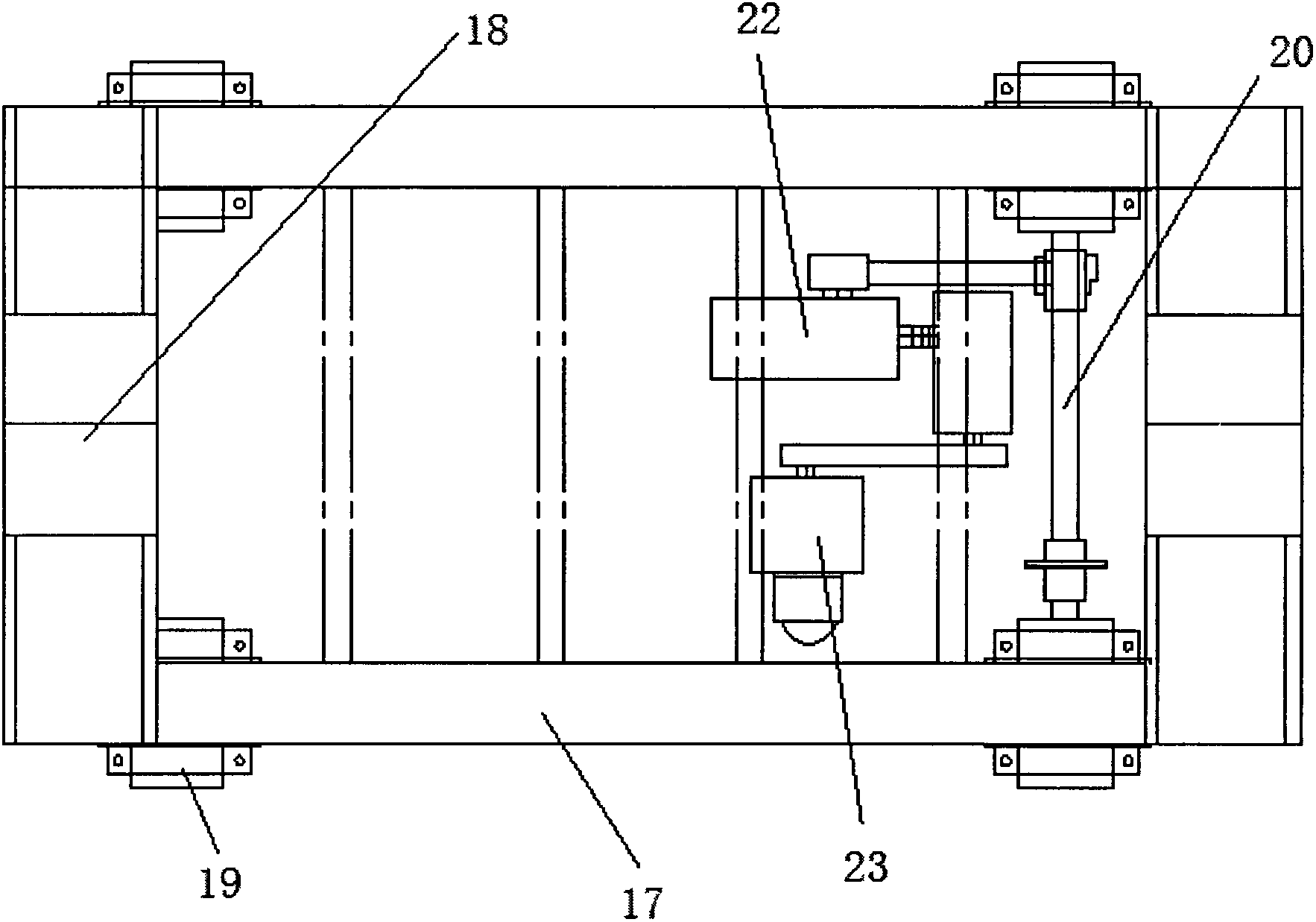

[0018] See Figure 1-3 , Tapered steel pipe straight seam single-side welding and double-side forming welding device, including adjustable welding device, welding bracket 10 and carrying trolley.

[0019] The adjustable welding device includes a vertical pole 12, the vertical pole 12 is connected with a telescopic sleeve 14 through a sliding device 13, and the sliding device 13 is connected to the motor 11 on the top of the vertical pole 12 through a rope. The telescopic sleeve 14 is provided with a telescopic rod 16 , The end of the telescopic rod 16 is provided with a welding device 15 (welding machine).

[0020] A tapered steel pipe 1 is placed at the bottom of the welding device 15. A welding bracket 10 is provided in the tapered steel pipe 1, and the tapered steel pipe 1 is placed on the carriage.

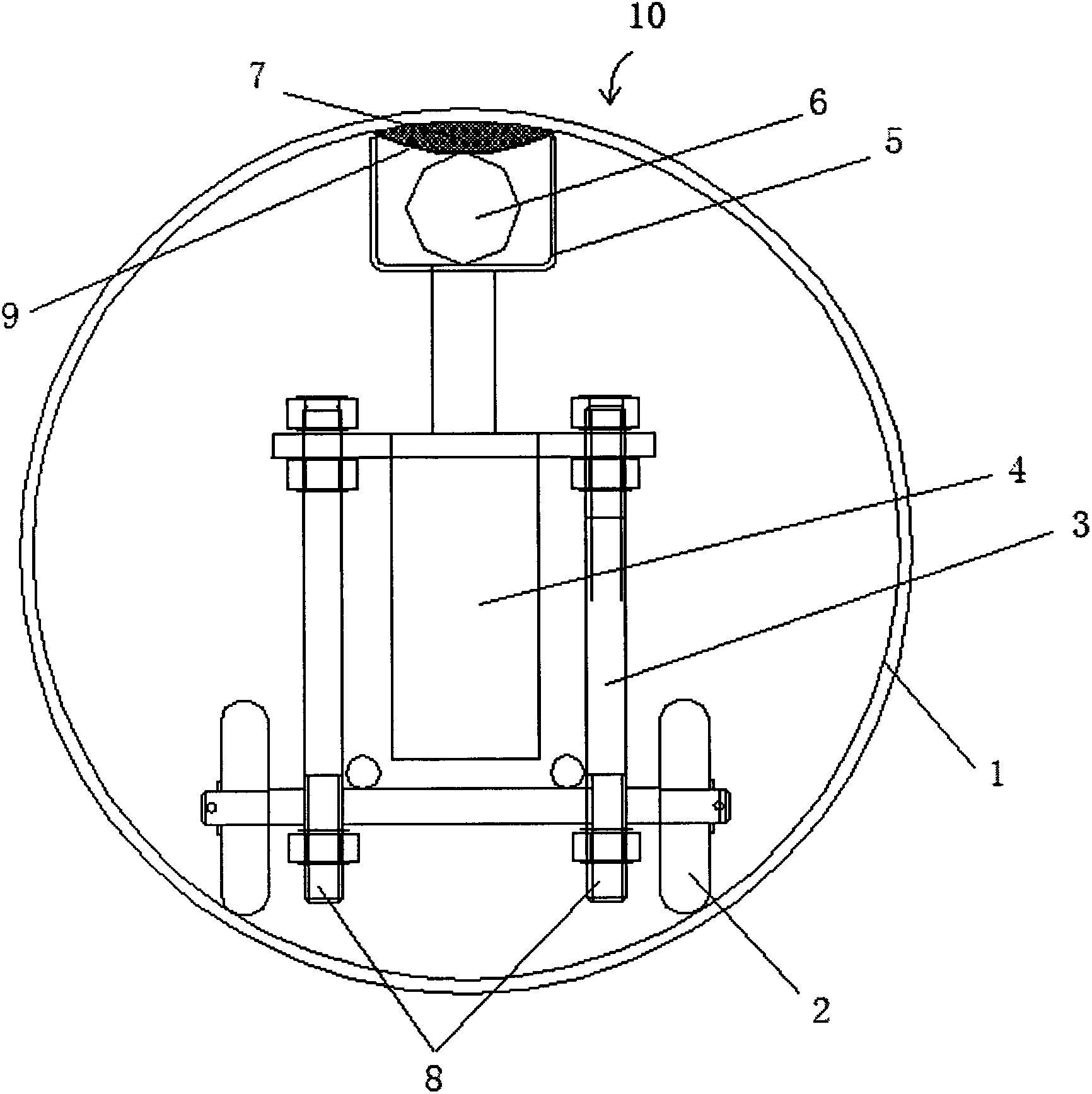

[0021] The welding bracket 10 includes a bracket 3, and two sides of the bottom of the bracket 3 are provided with rollers 2 which drive the bracket 3 to move in the tapered steel p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap