Heat-insulating agent composition

A technology of heat insulating agent and composition, applied in the direction of iron compound, aluminum compound, synthetic resin layered product, etc., can solve the problem of not showing visible light transmittance or heat insulating coating performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] (Heat Insulator No.1)

[0131] Na 1.1 [Al 0.4 Fe 0.6 ] 3.0 (SO 4 ) 2.2 (OH) 5.7 3.1H 2 O (2)

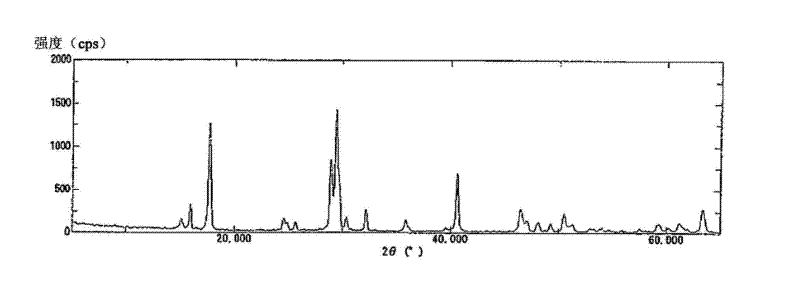

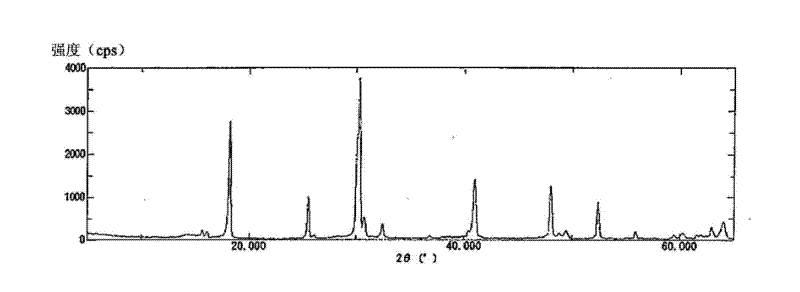

[0132] 78.5mL (0.081mol) of 1.037mol / L aluminum sulfate aqueous solution, iron sulfate (Fe 2 (SO 4 ) 3 ·xH 2 O) 48.27g (0.1207 mol) and sodium sulfate (Na 2 SO 4 ) 28.4 g (0.3 mol) of the mixed solution 500 mL was stirred at 40° C. for 30 minutes. Then, 230.7 mL of a 3.38 N aqueous sodium hydroxide solution was added to the mixed solution, followed by stirring at 40° C. for 1 hour. Afterwards, it was hydrothermally reacted at 170° C. for 3 hours, filtered, washed and dried to obtain polyhedral transition metal salt hydroxide (insulation agent No. 1). The reaction molar ratio [Al]:[Fe] at this time was 1:1.5. The X-ray diffraction pattern of heat insulating agent No.1 is as follows figure 1 As shown, the SEM photo (×20,000) as Figure 4 shown. In addition, the particle size distribution of heat insulating agent No.1 is as follows Figure 9 shown.

[0133] (...

Embodiment 2

[0154] (Preparation of thermal insulation coating agent)

[0155] Acrylic resin (trade name: SUMIPEX MGSS / manufactured by Sumitomo Chemical Co., Ltd.) was added to a mixed solvent of toluene, 2-butanone and butyl acetate, and stirred at room temperature for a whole day and night to prepare a polymethacrylic acid solution. In the case of coating under the conditions of 25°C and 60%RH, the amounts of toluene, 2-butanone 20mL, and butyl acetate can be 50mL, 20mL, and 20mL respectively with respect to 20g of acrylic resin. Fine-tune the temperature and humidity to the appropriate amount. To this polymethacrylic acid solution, the fine particles of heat shielding agent prepared in Example 1 were added and dispersed uniformly to prepare a heat shielding coating agent.

Embodiment 3

[0157] (Preparation of thermal insulation film)

[0158] Place a biaxially stretched polyester film (trade name: ダイアホイル T680E / Mitsubishi Chemical polyester film) with a size of 70 mm × 70 mm × t100 μm on a flat plate (fixing plate) as a substrate, and drop 1 mL to prepare in Example 2 The thermal insulation agent was coated with an applicator YBA-4 (YOSHIMITSU Seiki), and then dried at room temperature for 2 hours to prepare a sample piece of thermal insulation film. At this time, the thickness of the heat-shielding layer immediately after coating was set at 25 μm (thickness after drying was about 1 / 5 of coating time). After drying, the thickness of the sample piece was measured with a sample piece thickness gauge, and the thickness of the coating layer was calculated based on the thickness of the base material, and it was confirmed that it was about 5 μm. Tables 2 and 3 show the preparation conditions of each heat insulation film sample piece.

[0159] Table 2

[0160]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com