Spark plug electrode produced from improved electrode material

A technology for electrode materials and spark plugs, applied in the direction of spark plugs, metal material coating technology, circuits, etc., to achieve the effects of improving conductivity, reducing transition resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

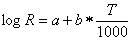

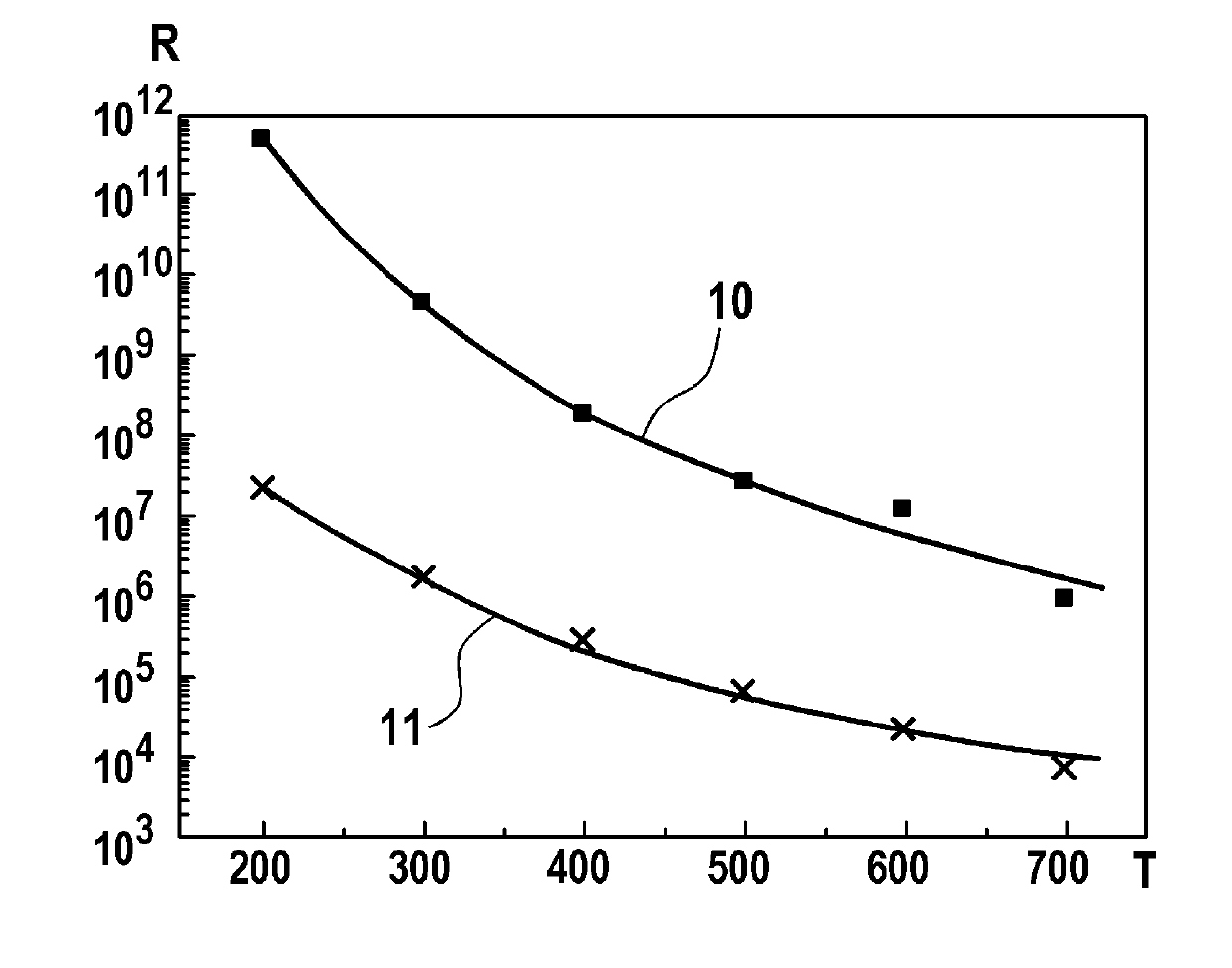

[0053] The following reference figure 1 , 3 , 4 and 5 describe spark plug electrodes according to embodiments of the present invention.

[0054] by figure 1 with figure 2 The comparison illustrates the advantages of the electrode material according to the invention or the spark plug according to the invention. figure 1 with 2 It is a micrograph taken with a scanning electron microscope by magnifying part of the electrode 500 times. in figure 1 with figure 2 Here, reference numeral 1 identifies the corresponding electrode base material. Reference numeral 2 identifies the surface of the electrode material on which the oxide layer 3 has been formed. In addition, there is a gas chamber 4 into which electrodes are introduced.

[0055] figure 1 Is a micrograph of the nickel alloy according to the present invention, wherein the nickel alloy according to the present invention contains 0.2 weight percent of hafnium relative to the total weight of the electrode material as element b) and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap