Grounding sleeve of generator rotor

A generator, bushing technology, applied in electrical components, circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve problems such as short circuit, damage to rectifier components, and diode reverse bias damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

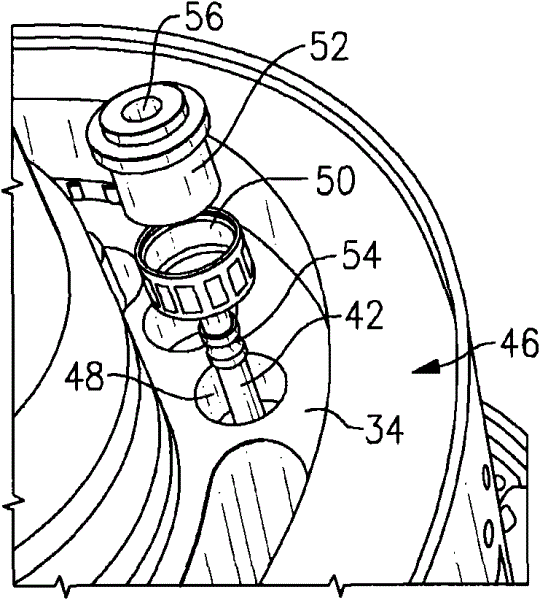

[0010] figure 1 Generators 10 of the type shown are commonly used in aerospace applications. The generator 10 includes main, field and permanent magnet generator (PMG) components 14 , 16 , 18 . In one embodiment, the main, field and PMG components 14 , 16 , 18 include first, second (field) and third rotors 22 , 24 , 26 , respectively, supported by a common shaft 20 rotatable about axis A, respectively. During rotation, the first, second and third rotors 22, 24, 26 respectively cooperate with the first, second and third stators 28, 30, 32 to rotate each of the main, field and PMG components 14, 16, 18. An alternating current is generated in one.

[0011] figure 2 The field rotor 24 is schematically depicted. The field rotor 24 includes a rotor frame 34 that supports a rotor circuit 35 . The field armature coil 38 in the rotor circuit 35 induces an alternating current through the rectification means 36 . The diode 40 in the rectifying section 36 rectifies the alternating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com