Preparing method of FePt/graphene composite nano materials

A graphene composite and nano-material technology, applied in the field of nano-materials, can solve problems such as easy agglomeration and affecting performance, and achieve the effects of simple synthesis steps, reduced production costs, and special and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

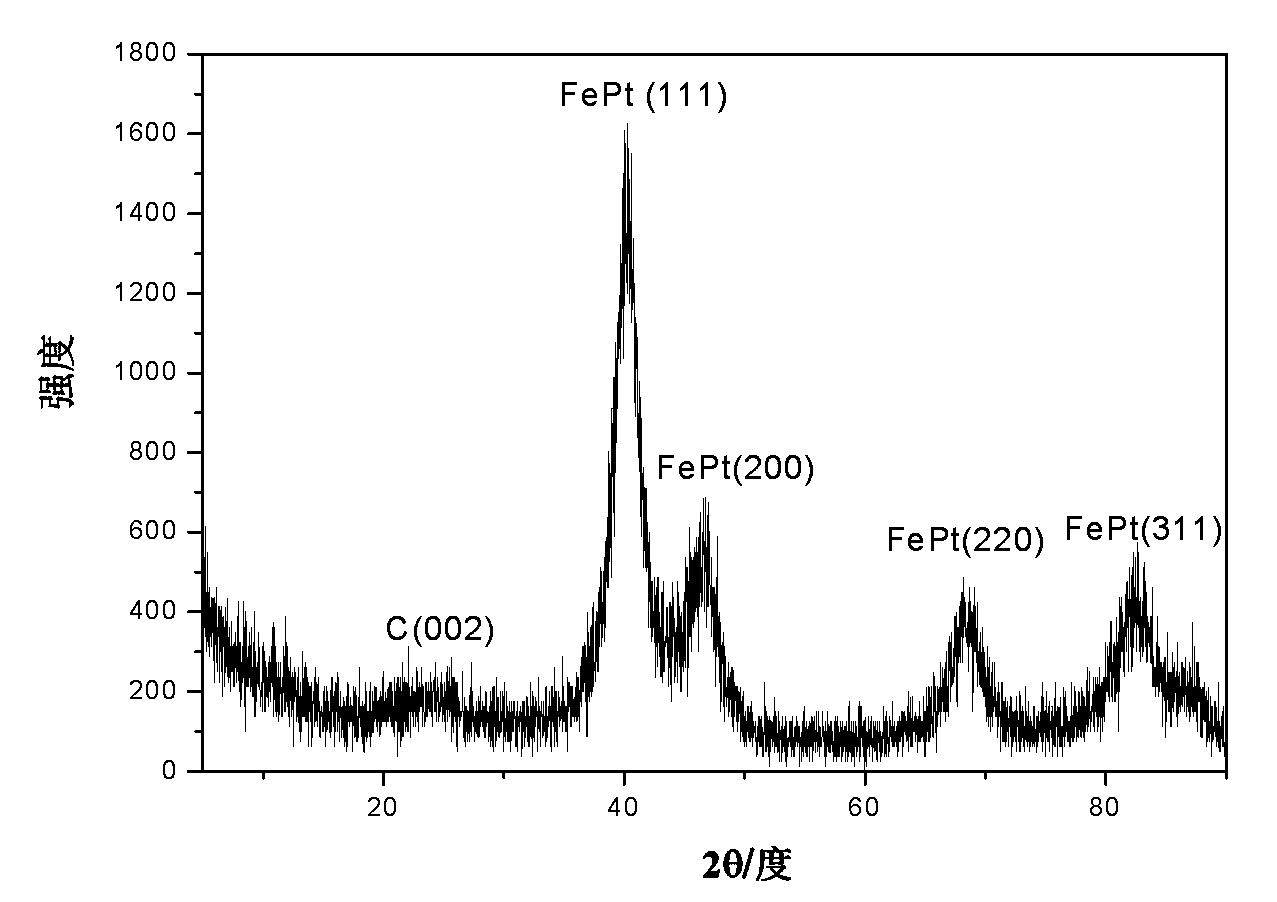

Embodiment 1

[0033] Weigh 20 mg of graphene oxide, place it in 10 mL of deionized water for ultrasonic dispersion, and obtain a uniform aqueous solution of graphene oxide A; weigh 0.0985 g of platinum acetylacetonate and 0.0883 g of iron acetylacetonate, and place mL of ethylene glycol, heated under magnetic stirring to dissolve, respectively, to obtain transparent solution B and transparent solution C; add solution C dropwise to solution B, and stir for 15 min to obtain solution D; then add solution A dropwise to In solution D, after stirring for 30 min, transfer to a 50 mL polytetrafluoroethylene reactor, and react at 160°C for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, and the obtained product was alternately centrifuged and washed three times with absolute ethanol and deionized water, and then dried in a vacuum oven at 60° C. for 4 hours to obtain the FePt nanoflower / graphene composite material. The speed of centrifugation is 10000 rpm, and...

Embodiment 2

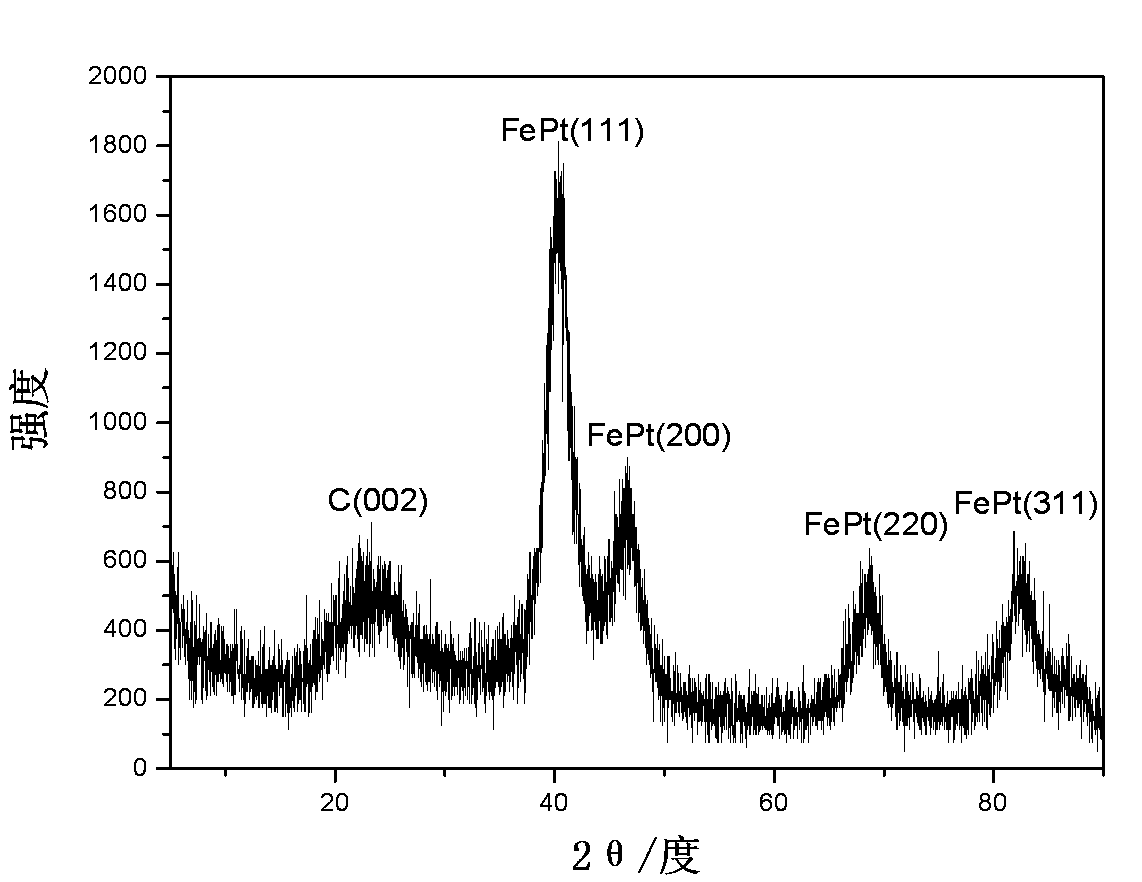

[0036] Weigh 50 mg of graphene oxide, place it in 10 mL of deionized water for ultrasonic dispersion, and obtain a uniform aqueous solution A of graphene oxide. Weigh 0.0985 g of platinum acetylacetonate and 0.0883 g of iron acetylacetonate, place them in 15 mL of ethylene glycol, and heat to dissolve under magnetic stirring to obtain transparent solution B and transparent solution C respectively; Add solution B and stir for 15 minutes to obtain solution D; then add solution A dropwise to solution D, stir for 30 minutes, transfer to a 50 mL polytetrafluoroethylene reactor, and react at 160°C for 24 hours. After the reaction was finished, it was naturally cooled to room temperature, and the obtained product was alternately centrifuged and washed three times with absolute ethanol and deionized water, and then dried in a vacuum oven at 60° C. for 4 hours to obtain the FePt nanoparticle / graphene composite material. The speed of centrifugation is 10000 rpm, and the time is 5 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com