Symmetric speed reducer for mining conveying and transporting winch

A symmetrical, reducer technology, applied in hoisting devices, spring mechanisms, etc., can solve the problems of high noise, serious friction and heat, and high noise in use, and achieve high transmission efficiency, good braking effect, and improved work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

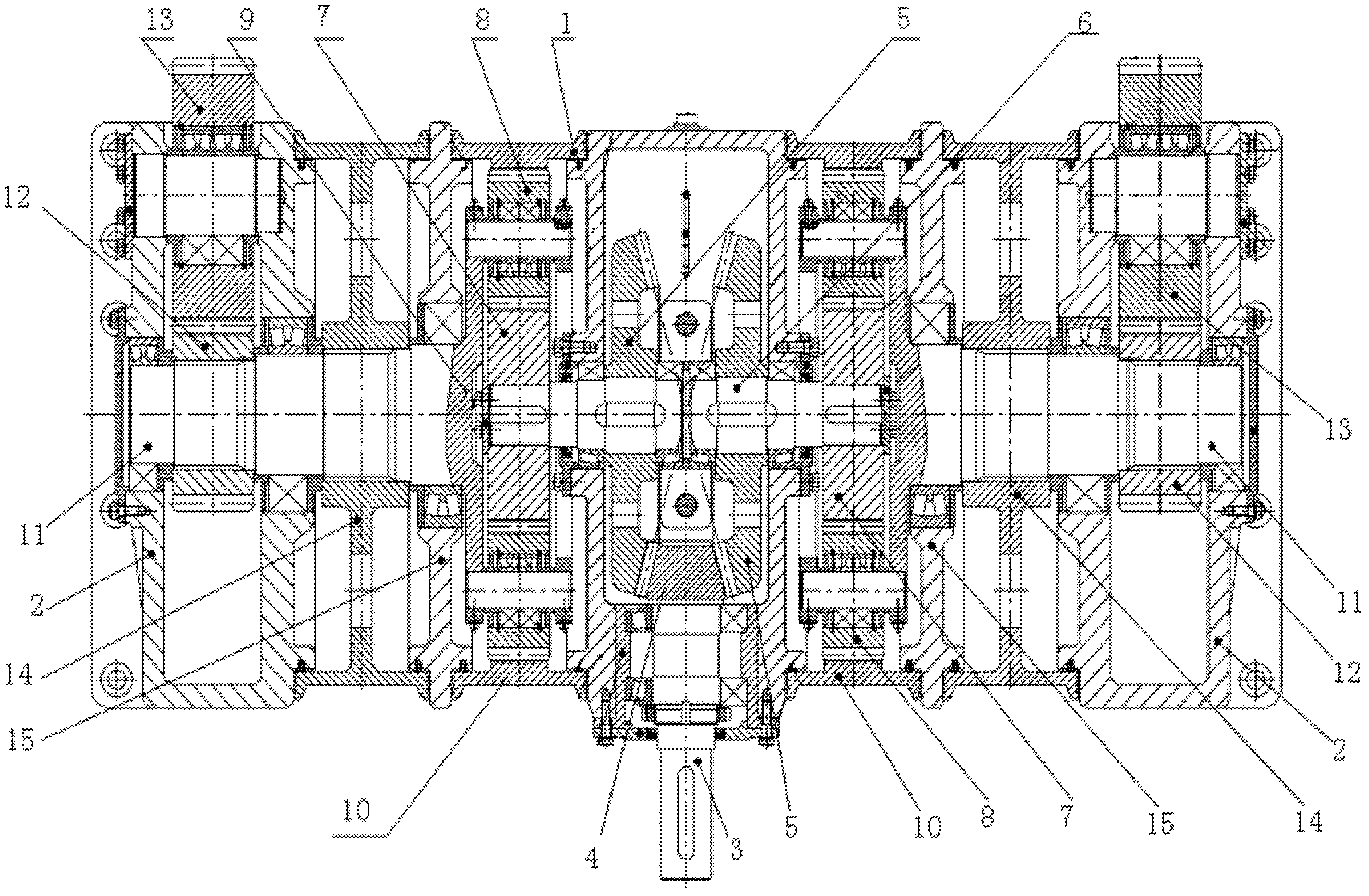

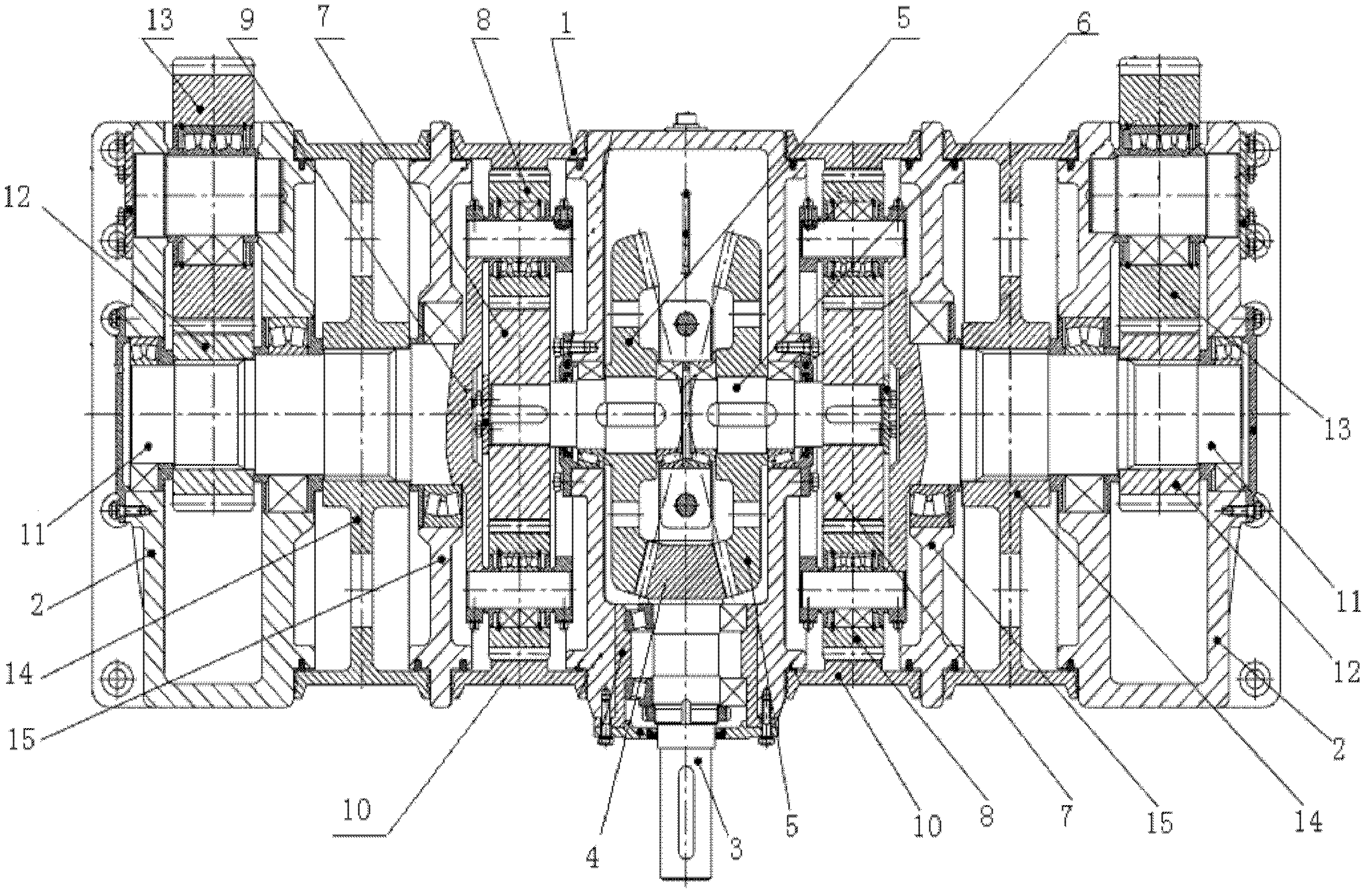

[0011] Referring to the accompanying drawings, the symmetrical reducer for the mining transport winch includes a bevel gear box 1 and a bridge gear box 2, and a vertical input shaft 3 is installed on one side of the bevel gear box 1, and the end of the input shaft 3 A shaft gear 4 is installed, and the two sides of the shaft gear 4 are respectively meshed with a large gear 5, and the large gears 5 on both sides are respectively installed on the front end of the horizontal flat key shaft 6, and the rear end of the flat key shaft 6 is equipped with a central gear 7 , the central gear 7 is externally meshed with several planetary gears 8, and the planetary gears 8 are respectively rotated and installed on the turntable 9 of the planetary carrier. The two sides of the bevel gearbox are respectively fixed with internal gear rings 10 that match the planetary gears. The rotating shaft of the planetary carrier 11 is fixedly installed with a pinion 12, and the pinion 12 is externally me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com