Unilateral speed reducer for mining conveying and transporting winch

A reducer and handling technology, which is applied in the field of single-sided reducers for mining transportation winches, can solve the problems of high noise, serious friction and heating, and high operating noise, and achieves high transmission efficiency and good braking effect. , the effect of ergonomics improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

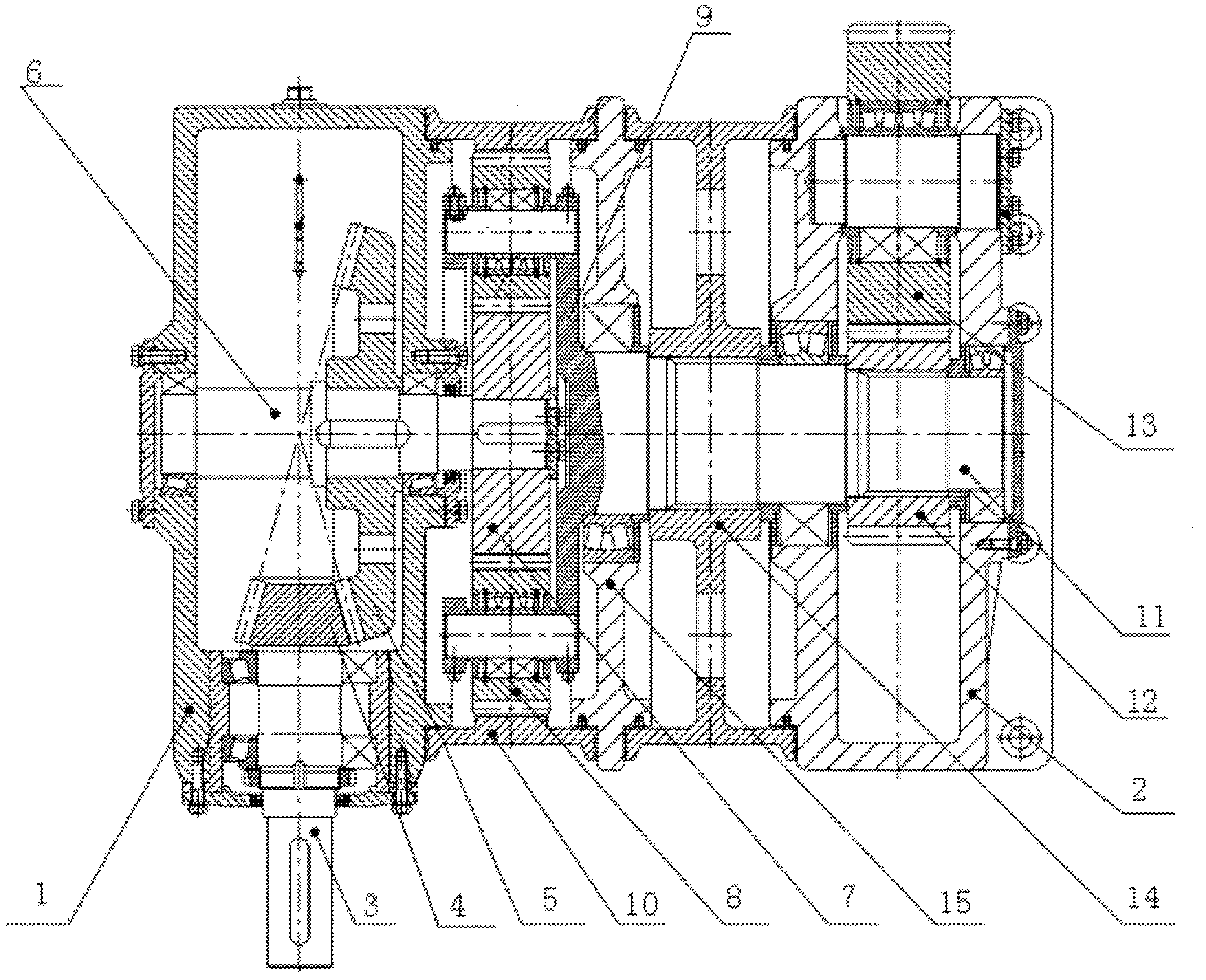

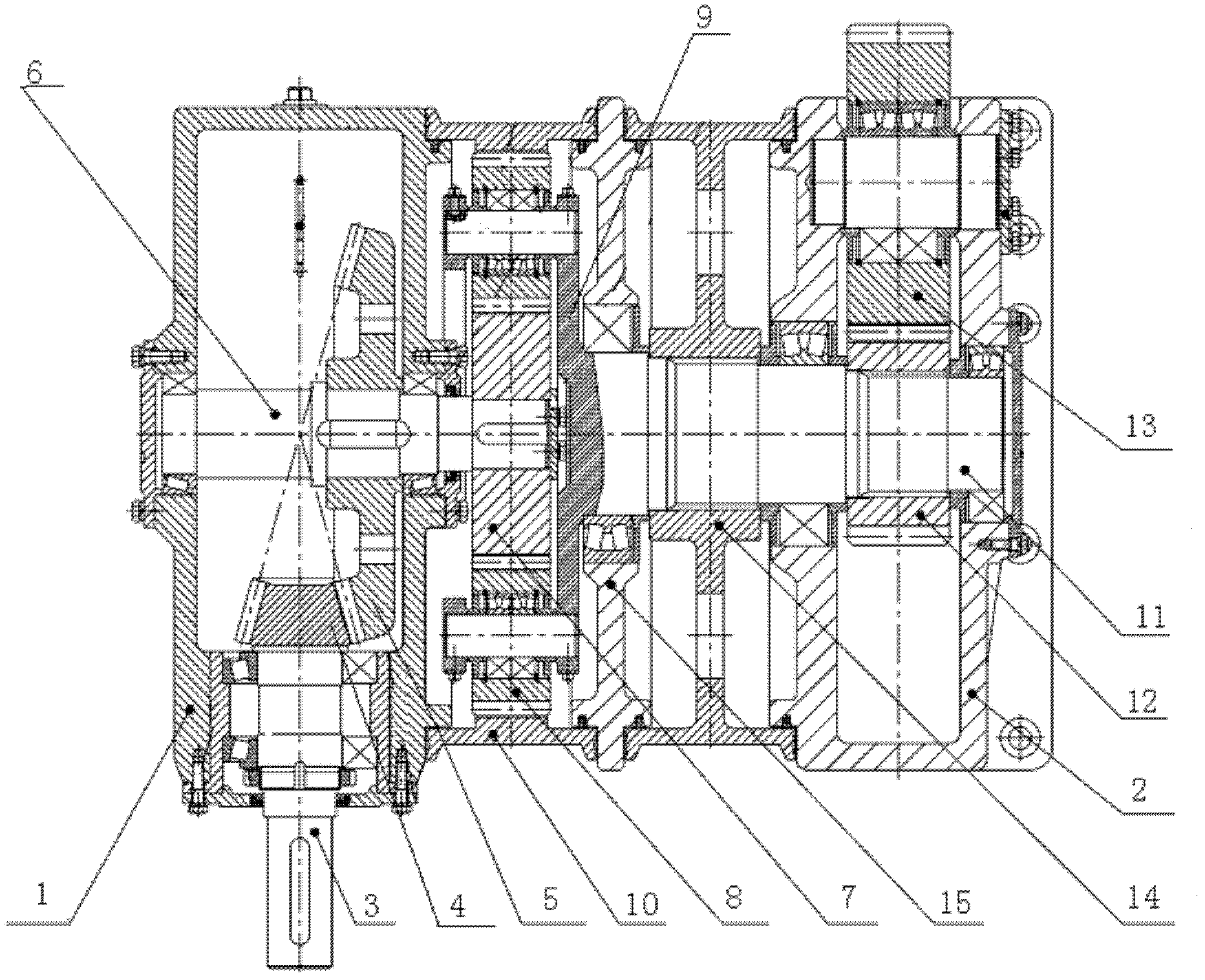

[0011] Referring to the accompanying drawings, the one-sided speed reducer for mine handling and transportation winches includes a bevel gearbox 1 and a bridge gearbox 2. One side of the bevel gearbox 1 is rotated and installed with a longitudinal input shaft 3, and the end of the input shaft 3 Shaft gear 4 is installed at the top of the shaft gear 4, and the meshing of shaft gear 4 has large gear 5. The large gear 5 is installed on the front end of the horizontal flat key shaft 6 respectively, and the rear end of the flat key shaft 6 is equipped with a central gear 7, and the external center gear 7 Several planetary gears 8 are meshed, and the planetary gears 8 are rotatably installed on the turntable 9 of the planetary carrier. An inner ring gear 10 matching the planetary gears is fixedly installed on the side wall of the bevel gearbox, and a small ring gear is fixedly installed on the rotating shaft 11 of the planetary carrier The gear 12 and the pinion 12 are externally mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com