Process for production of antimicrobial medical instrument, and antimicrobial medical instrument

A technology of medical equipment and manufacturing methods, applied in the fields of pharmaceutical formula, medical science, catheters, etc., can solve the problems of inability to maintain antibacterial properties for a long time, antibacterial agent falling off, etc., and achieve the effect of maintaining antibacterial properties for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] In Example 1, the antibacterial tube A was produced according to the production method described in the above-described embodiment, and a peeling test was performed to determine whether or not the antibacterial agent adhering to the surface of the antibacterial tube A was easily detached. Moreover, since the 2nd solvent which melt|dissolved a medical instrument was used, it also confirmed whether the shape of the antibacterial tube A was deformed or not.

[0089] In addition, as a comparative example, a solvent different from the mixed solvent of the present invention was prepared, and comparative examples 1 and 2 produced from the mixed solvent were prepared simultaneously, and a test for deformation of the medical device and a peeling test for the antibacterial agent were performed together.

[0090] (Example 1)

[0091] Example 1 uses a polyurethane tube as a medical device. This urethane tube was made of urethane (manufactured by Nippon Milactron, trade name "E990"...

Embodiment 2、 comparative example 4

[0128] Example 2 Antibacterial tube E was produced in the same manner as in Example 1. In addition, the antibacterial tube F was manufactured similarly to the comparative example 2 in the comparative example 4.

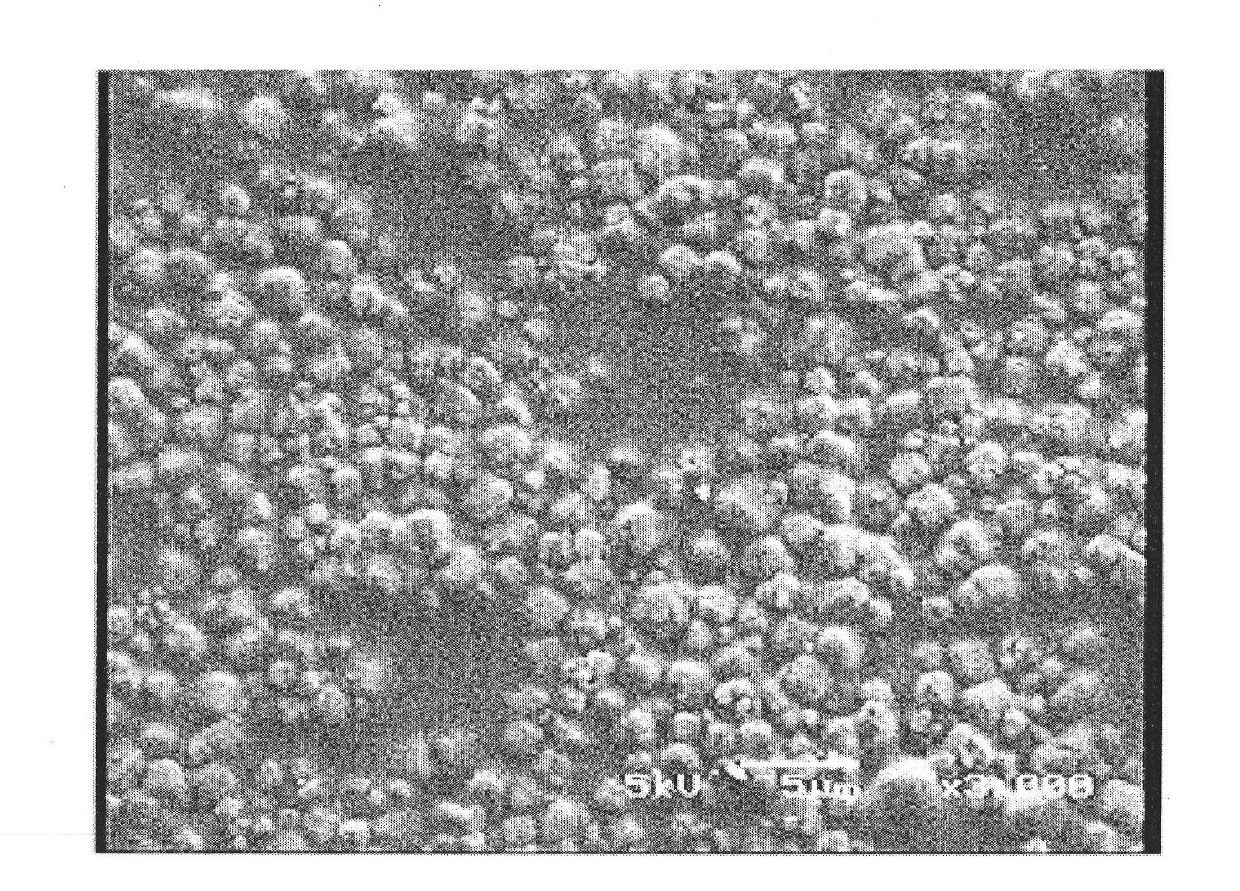

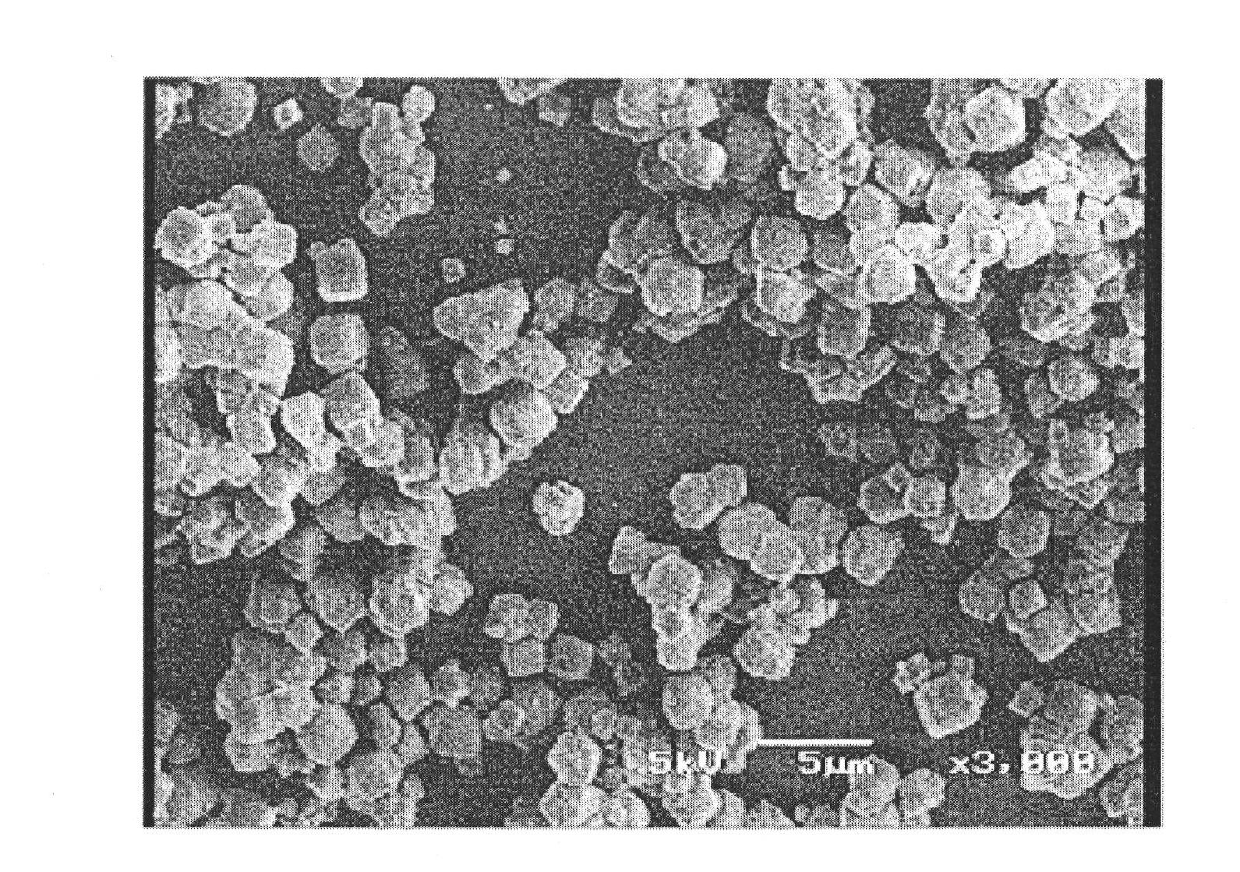

[0129] About the manufactured antibacterial tube E and antibacterial tube F, surface photograph (photographing direction: oblique to the tube surface, magnification: 3000 times) and a cross-sectional photograph (magnification: 3000 times), and the state of the antibacterial agent dissolved on the surface was visually confirmed. Furthermore, surface photos ( Figure 8 , Figure 10 ), cross-section photos ( Figure 9 , Figure 11 ), the antibacterial agent was photographed as granular.

[0130] It can be confirmed that the antibacterial tube E of Example 2 is as Figure 8 , Figure 9 As shown, a part of the antibacterial agent was dissolved on the surface of the antibacterial tube E in an exposed state. From this, it turned out that the antibacterial tube E did ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com