Tooth-roller crusher

A crusher and toothed-roller type technology, applied in the field of toothed-roller crushers, can solve the problems of complex manufacturing process and high cost, achieve high crushing efficiency, consume less precious metals, and achieve the effect of overload protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

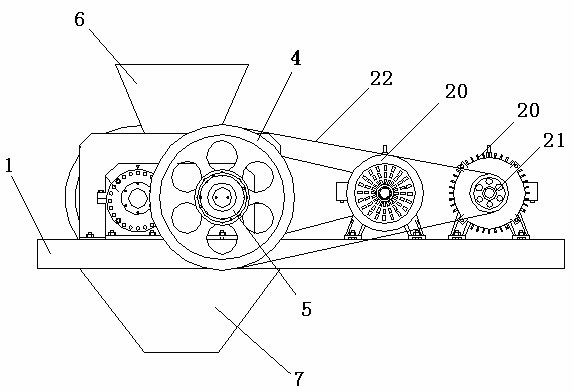

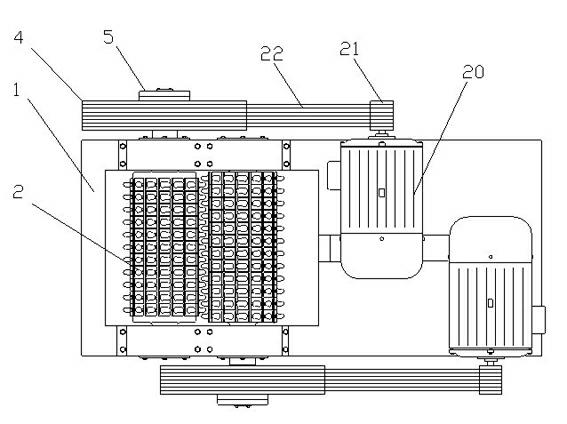

[0022] see Figure 1 to Figure 6 , the present invention proposes a toothed roller crusher, which includes a frame 1 on which a group of matched toothed rollers 2 are installed.

[0023] The toothed roller 2 includes a roller shaft 3 .

[0024] The outer end of the roller shaft 3 of each toothed roller 2 is fitted with a flywheel 4 and a safety disc 5 .

[0025] A feed hopper 6 is arranged on the frame 1 above the meshing portion of the toothed roller 2 , and a discharge hopper 7 is arranged below the meshing portion of the toothed roller 2 .

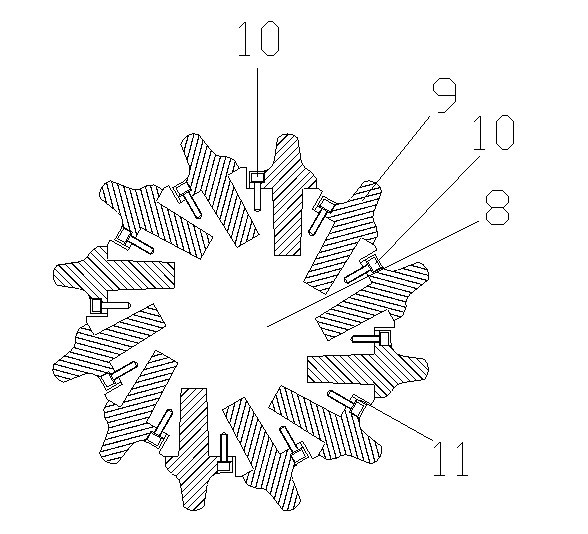

[0026] The toothed roller 2 includes a roller body 8 , column teeth 9 and screws 10 .

[0027] The surface of the roller body 8 is provided with several stepped installation grooves 11 , and the installation grooves 11 are distributed along the circumferential direction of the roller body 8 .

[0028] A row of stud holes (not marked) and a row of screw holes (not marked) are respectively provided on the groove surface of each mountin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap