Manufacturing method of pneumatic tire

A technology for pneumatic tires and manufacturing methods, applied to tires, other household appliances, household appliances, etc., can solve problems such as unfavorable tire production, and achieve the effects of suppressing unevenness, suppressing the reduction of durability, and suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

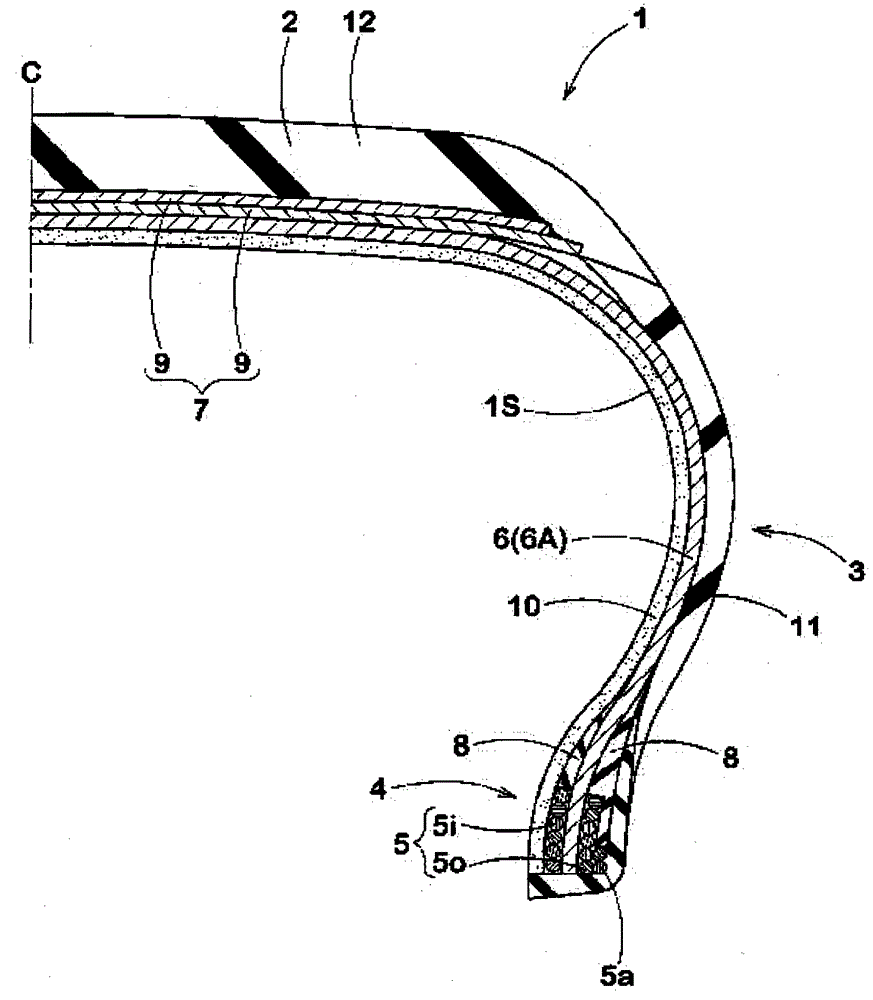

[0048] Based on the manufacturing method of the present invention using a rigid core, according to the specifications in Table 1, a figure 1 Pneumatic tires (tire size 175 / 65R14) of the internal construction indicated, and the uniformity, durability and entrapped air of each test tire were tested. Also for comparison, if Figure 9 As shown, as Comparative Example 1, a wide-band-shaped ply material was used, and the ply material was wound around a rigid core in the circumferential direction for one turn, and the conventional method of sewing both axial sides of the tire was used to manufacture A tire formed with a belt ply was compared with the examples. In addition, Comparative Examples 2 and 3 and Examples 1 to 3 differ only in the belt width Wt of the cut belt piece, and at the outer end of the belt ply, the side edges of the cut belt piece are butted against each other (De=0). Also, in Comparative Example 4, between the side edges of the belt cut pieces at the outer end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com