Amide polyamine polycarboxylic acid high-polymer cement grinding aid and preparation method thereof

A technology of amide polyamine polycarboxylic acid and cement grinding aid, which is applied in the field of amide polyamine polycarboxylic acid polymer cement grinding aid and its preparation, and can solve problems such as unsatisfactory performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

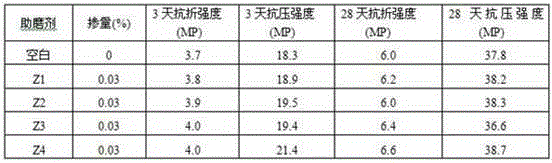

[0021] Prepare amide polyamine polycarboxylate polymer cement grinding aid Z1, add 9.8 g (0.1 mol) maleic anhydride, 5.76 g (0.08 mol) acrylic acid, 9.81 g (0.1 mol) allyl ether in a 250ml three-necked flask , 5.68 g (0.08 mol) of acrylamide and 85 g of water, after the temperature was raised to 55 ° C to fully dissolve the maleic anhydride, 1.14 g (5 mmol) of ammonium persulfate dissolved in 20 g of water was added dropwise at a rate of 0.5 ml / min to initiate Add the initiator dropwise while raising the temperature at 5°C / min, keep the temperature at 90°C and continue stirring for 4 h, stop stirring and keep warm for 1 h, after cooling to room temperature, adjust the pH value to 7 with 30% NaOH aqueous solution (neutral). The solid content of the synthesized amidopolyamine polycarboxylate polymer was 27.3wt%.

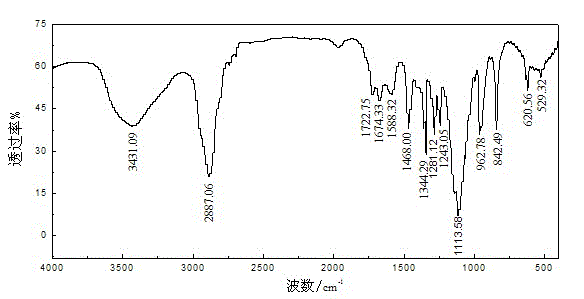

[0022] The infrared spectrogram of the present embodiment amide polyamine polycarboxylic acid series polymer grinding aid is as follows figure 1 shown. From figur...

Embodiment 2

[0024] Prepare the following amide polyamine polycarboxylate polymer cement grinding aid Z2, the polymerized monomers are 6.13 g (0.0625 mol) maleic anhydride, 7.2 g (0.1 mol) acrylic acid, 6.13 g (0.0625 mol) allyl ether , 7.11 g (0.1 mol) of acrylamide, 0.72 g (3.125 mmol) of initiator ammonium persulfate were dissolved in 65 g of water (?). Its preparation method is with embodiment 1.

Embodiment 3

[0026] Prepare the following amide polyamine polycarboxylate polymer cement grinding aid Z3, the polymerized monomers are 4.9 g (0.05 mol) maleic anhydride, 8.65 g (0.12 mol) acrylic acid, 4.9 g (0.05 mol) allyl ether , 8.53 g (0.12 mol) of acrylamide, 0.57 g (2.5 mmol) of initiator ammonium persulfate were dissolved in 65 g of water. Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com