Shape memory alloy heat engines and energy harvesting systems

A heat engine, energy harvesting technology, applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve the problems of heat and waste that cannot be found or designed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

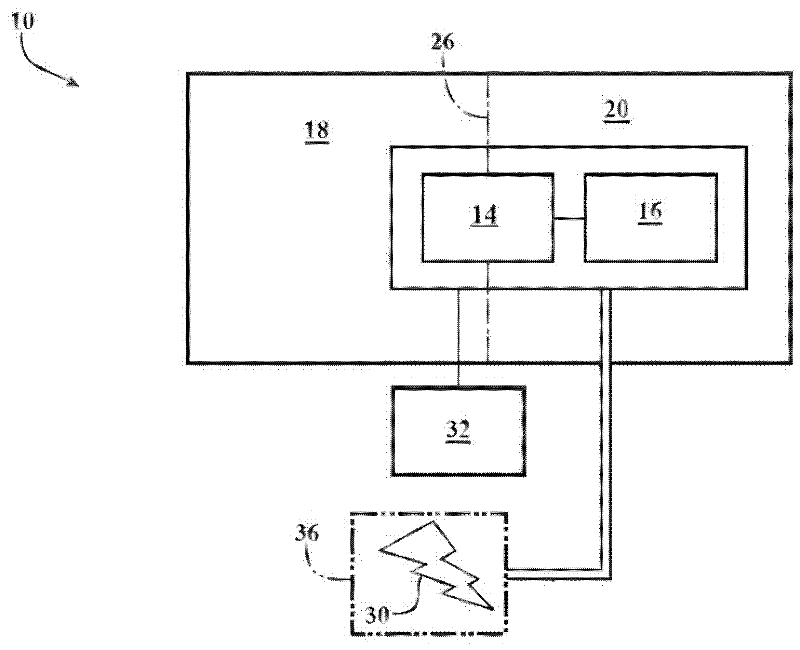

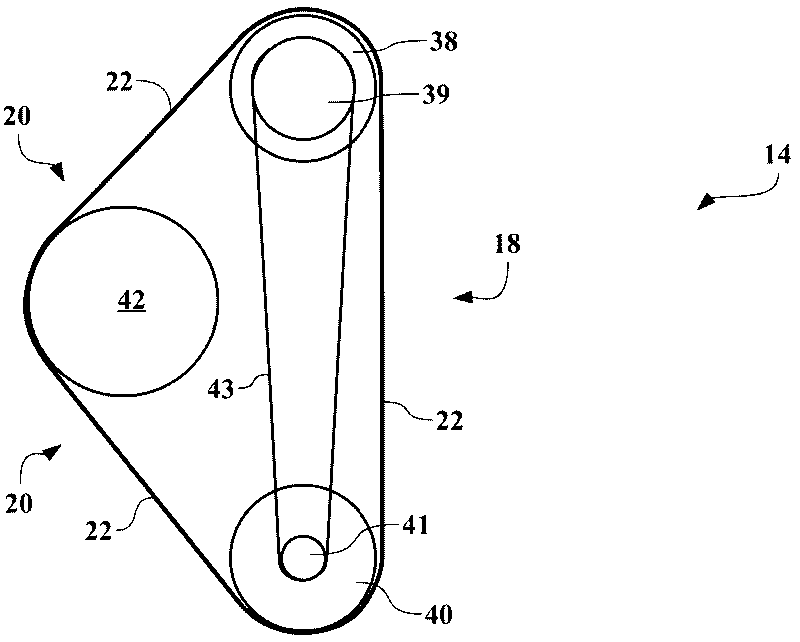

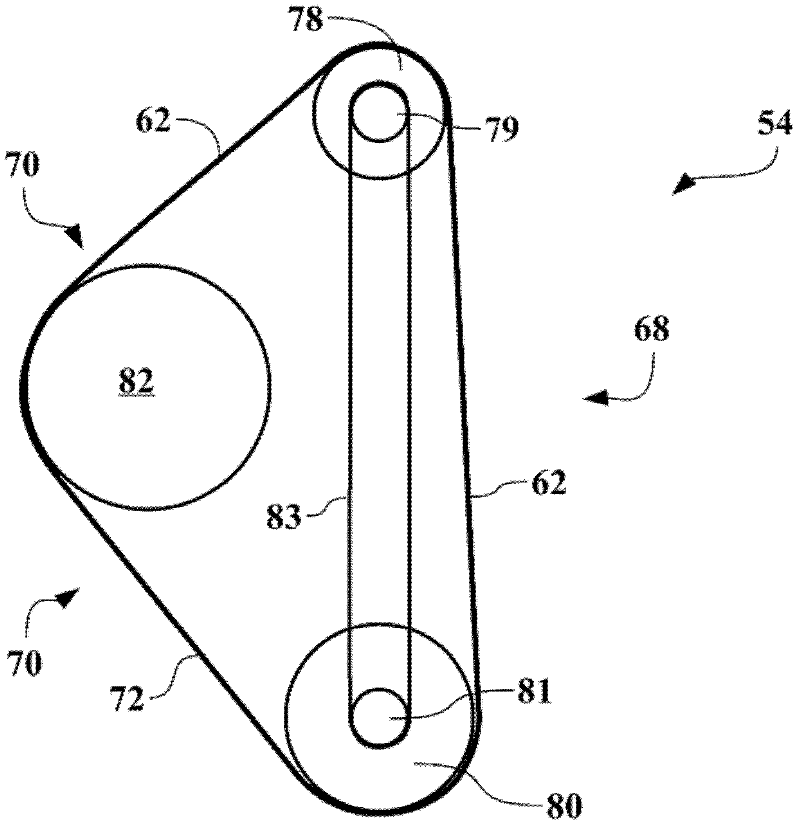

[0029] Referring to the drawings, in which like reference numerals correspond to like or similar parts wherever possible throughout the several views, in figure 1 A heat recovery system or energy harvesting system is shown in . Features and components described and shown in other figures may be incorporated into and with figure 1 used together as shown in . The illustrated energy harvesting system 10 includes a heat engine 14 and a driven component 16 .

[0030] Energy harvesting system 10 utilizes a first fluid region or thermal region 18 having a first temperature. Thermal region 18 is in thermal transfer communication with a heat source, such as waste heat, or may represent any region of relatively warmer temperatures that contributes to the operation of heat engine 14 , as described herein. The energy harvesting system 10 also utilizes a second fluid region or cold region 20 having a second temperature that is generally lower than the first temperature of the hot region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com