A deep well electric heating igniter and its application method

A technology of electric heating and igniter, applied in combustion ignition, combustion method, incandescent ignition, etc., can solve problems such as waste of energy, difficulty in controlling combustion temperature, loss of crude oil layer, etc., to avoid waste of crude oil, convenient temperature control, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

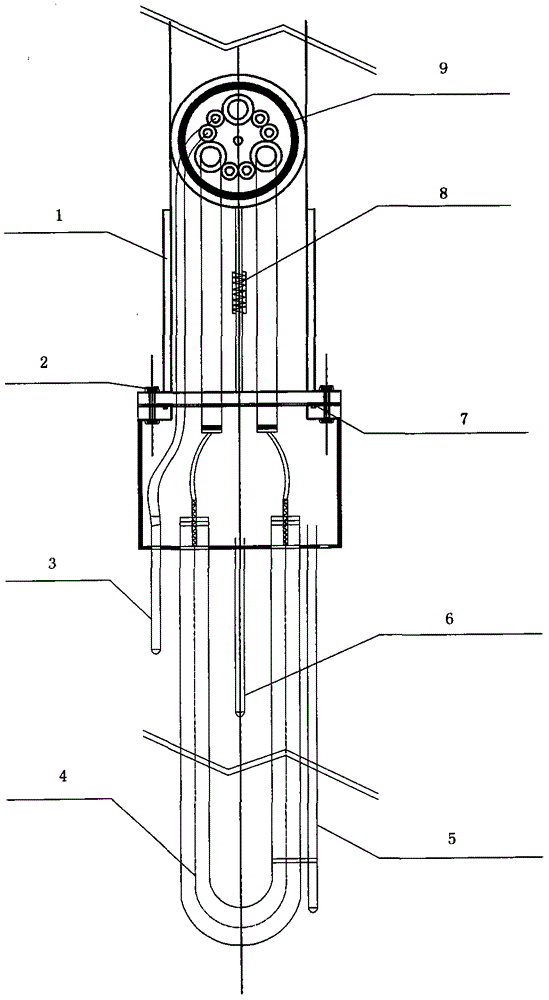

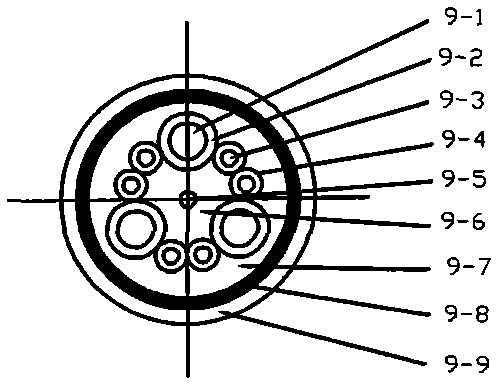

[0018] The deep well electric heating igniter of present embodiment is as figure 1 As shown, it includes a U-shaped electric heating tube 4, and the two ends of the U-shaped electric heating tube extend into the junction box from the bottom of the junction box 7, and a crude oil sensor 6 protruding from the bottom of the junction box 7 is placed in the middle (Sai, Foshan, Guangdong) Pute Electronic Instrument Co., Ltd. manufactures and sells the PTP703 type or Bengbu Tianguang Sensor Co., Ltd. manufactures and sells the BGY-1 model), and its two sides are respectively arranged with the first temperature sensor 5 and the second temperature sensor 3 protruding from the bottom of the junction box 7 . The first temperature sensor 5 is a high-temperature sensor for monitoring ignition temperature, and the second temperature sensor 3 is a low-temperature sensor for monitoring the temperature near the cable, and its detection ends are respectively adjacent to the lower end of the U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com