Four-die ultrasonic incremental extruding rolling compound molding apparatus for spline, and technology thereof

A compound forming and incremental technology, applied in metal rolling and other directions, can solve the problems of splines without ultrasonic metal plastic processing technology, and achieve the effect of good surface quality and performance, good balance and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

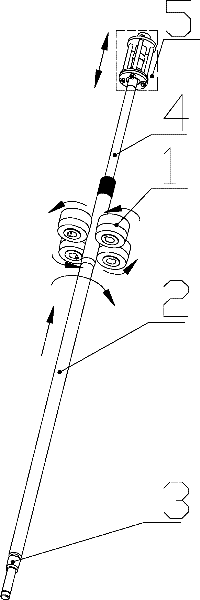

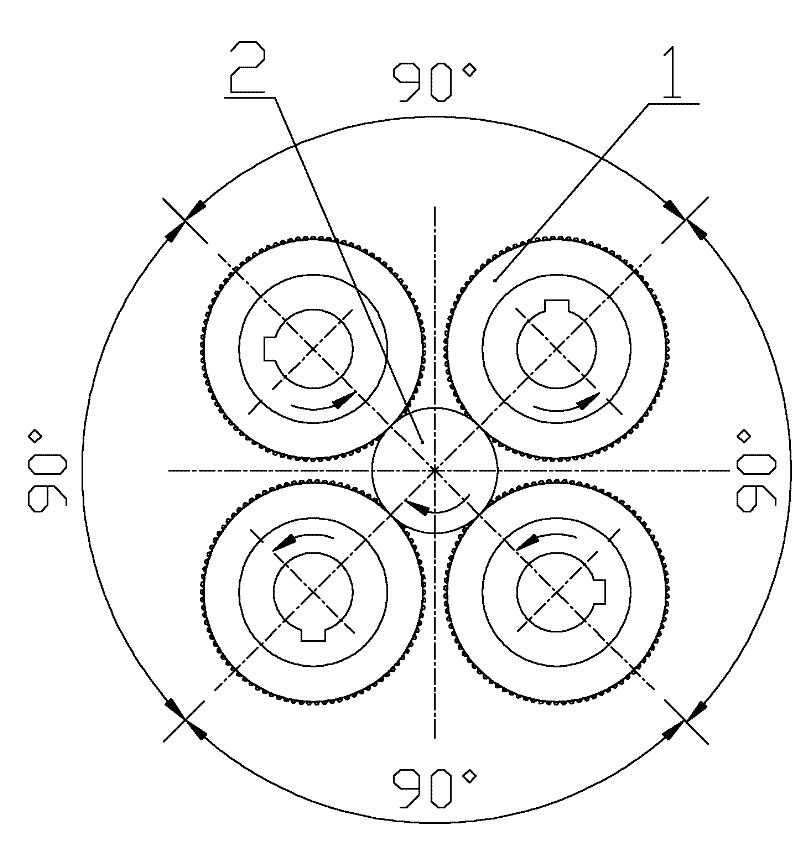

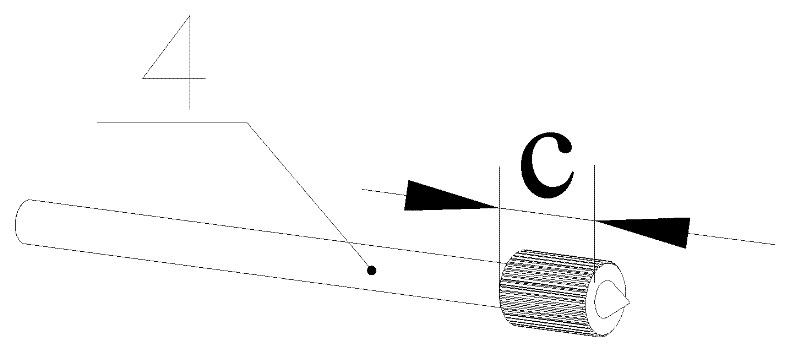

[0023] refer to figure 1 , a spline four-mold ultrasonic incremental extrusion-rolling compound forming device, including a front center 3 and a mold spline integrated center 4 that cooperates with it to clamp a workpiece 2, refer to figure 2 , there are four incremental extrusion-rolling composite forming dies 1 arranged in a 90° equidistant array along the circumferential direction of the workpiece 2, referring to image 3 , the spline segment c on the mold spline integrated top 4 is meshed with the incremental extrusion rolling compound forming mold 1 for transmission, and the rear end of the mold spline integrated top 4 is axially connected to the ultrasonic vibration device 5 .

[0024] A spline four-mold ultrasonic incremental extrusion-rolling composite forming process, comprising the following steps:

[0025] I), refer to figure 1 , the workpiece 2 is cla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap