Variable nozzle ring positioning structure

A positioning structure and nozzle ring technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low efficiency, large number of parts installed, poor versatility, etc., and achieve high efficiency, strong versatility of parts, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

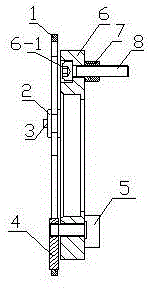

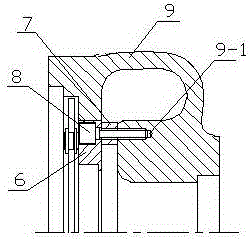

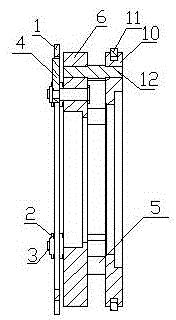

[0020] A variable nozzle ring positioning structure, which is to change the three countersunk screw mounting holes 6-1 on the blade seat 6 of the existing variable nozzle into three pin holes 6-2, and cancel the three countersunk screws 8 and three distance sleeves 7, then increase a disc-shaped back cover 10. The disc-shaped back cover 10 is provided with an annular groove 10-1 for installing a positioning retaining ring 11 on the radially outer circle, and the positioning retaining ring 11 is installed in the annular groove 10-1 on the outer circle of the disc-shaped rear cover 10, Three pin holes 10 - 2 are provided on the end surface of the disc-shaped rear cover 10 , and the three pin holes 10 - 2 are evenly distributed on the end surface of the disc-shaped rear cover 10 . The blade base 6 is connected with the disc-shaped back cover 10 through three step pins 12, one end of the step pin 12 and the pin hole 6-2 on the blade base 6 adopt an interference fit, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com