Metal mould rotary injection molding machine and rotation method of rotating table thereof

A technology of a rotary table and an injection molding machine, which is applied in the field of rotation of a metal mold rotary injection molding machine and its rotary table, can solve the problem that the rotation of the rotary table cannot be stabilized, the sleeve and the bearing are partially worn or damaged, and Problems such as high friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

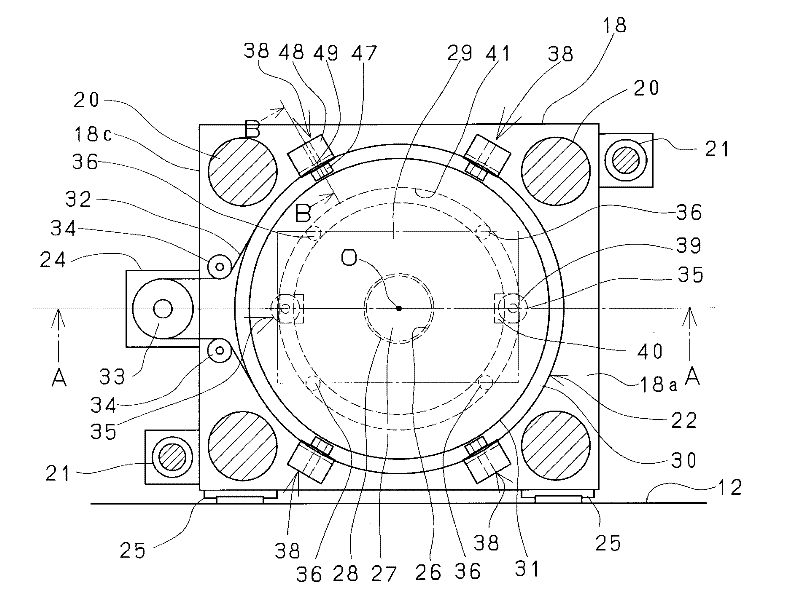

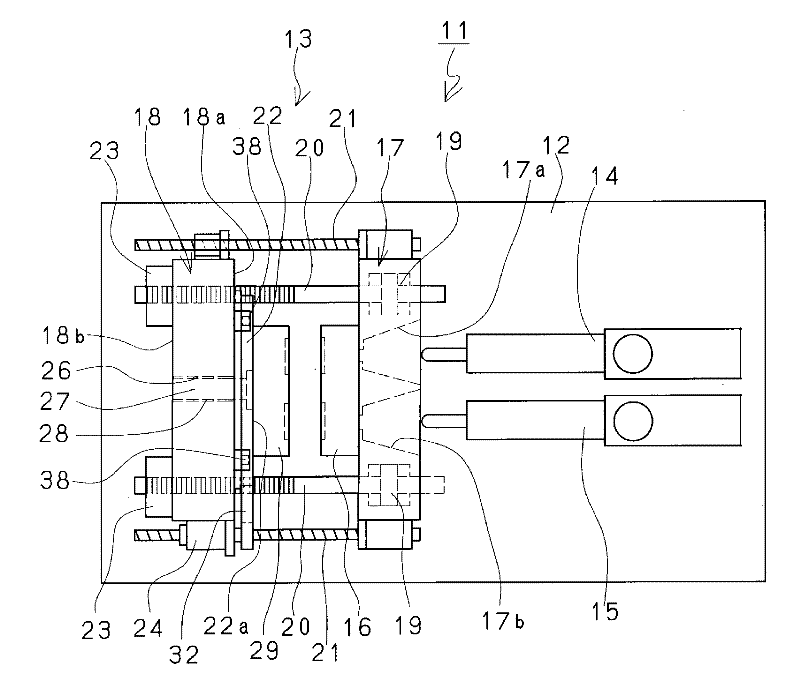

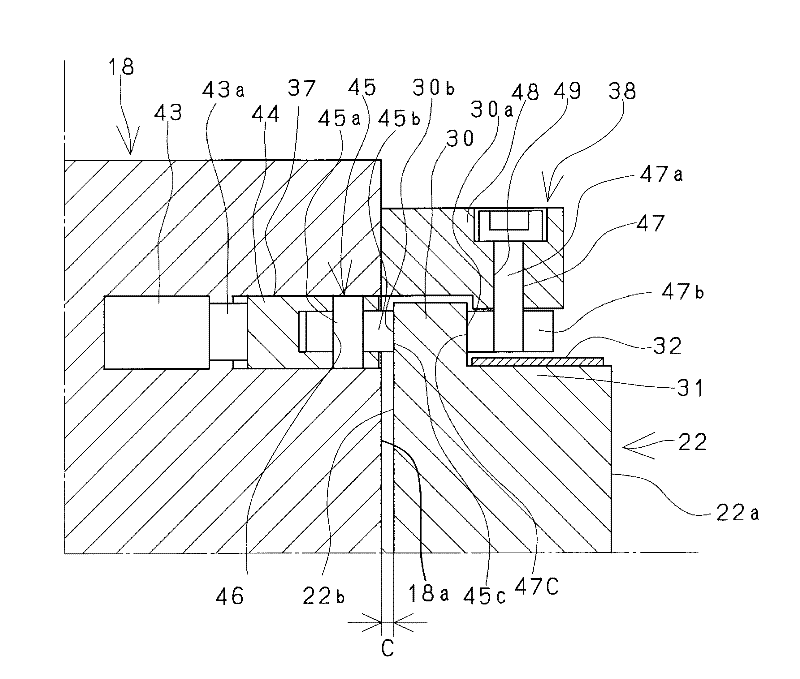

[0026] refer to figure 1 The outline of the mold rotary injection molding machine according to the embodiment of the present invention will be described. The mold rotary injection molding machine 11 basically includes a mold clamping device 13 provided on one side of a base 12 and injection devices 14 and 15 provided on the other side. The injection devices 14 and 15 are well known, and two injection devices are provided side by side for the purpose of injecting different materials, respectively. In addition, the configuration of the injection device is not limited to figure 1 In the illustrated structure, one injection device may be provided next to the mold clamping device, or a structure may have three or more injection devices.

[0027] In the description of the horizontal mold clamping device 13 , the fixed plate 17 on which the metal mold 16 is mounted is fixedly disposed on the base 12 . Furthermore, a movable platen 18 is disposed on the base 12 on the side (anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com