Physical vapor deposition equipment

A technology of physical vapor deposition and equipment, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as dropping and long process time, and reduce sticking problems and root-like protrusions The effect of reducing defects and process problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

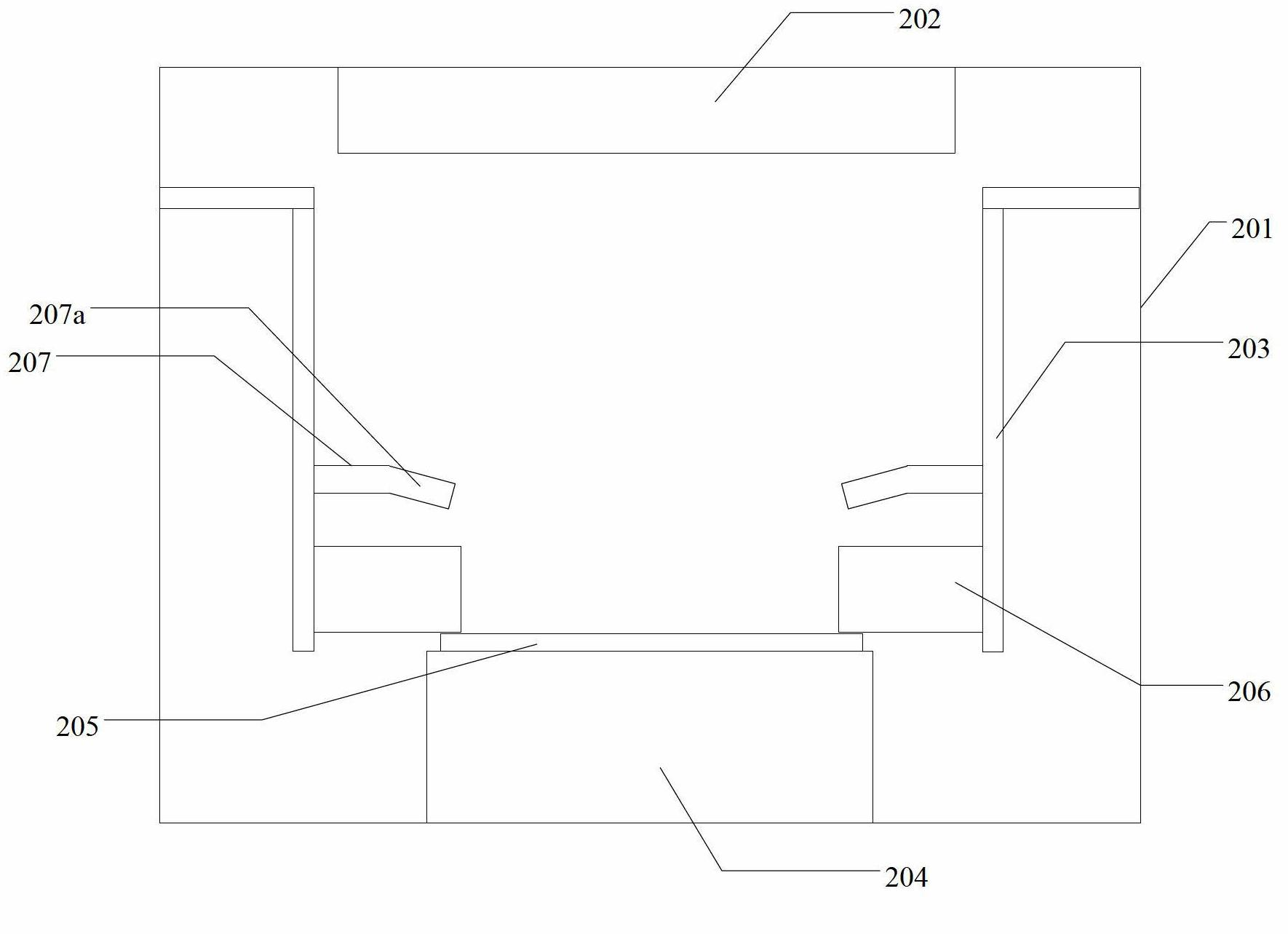

[0026] In order to better understand the physical vapor deposition equipment of the present invention, the structure of physical vapor deposition equipment in the prior art is described first.

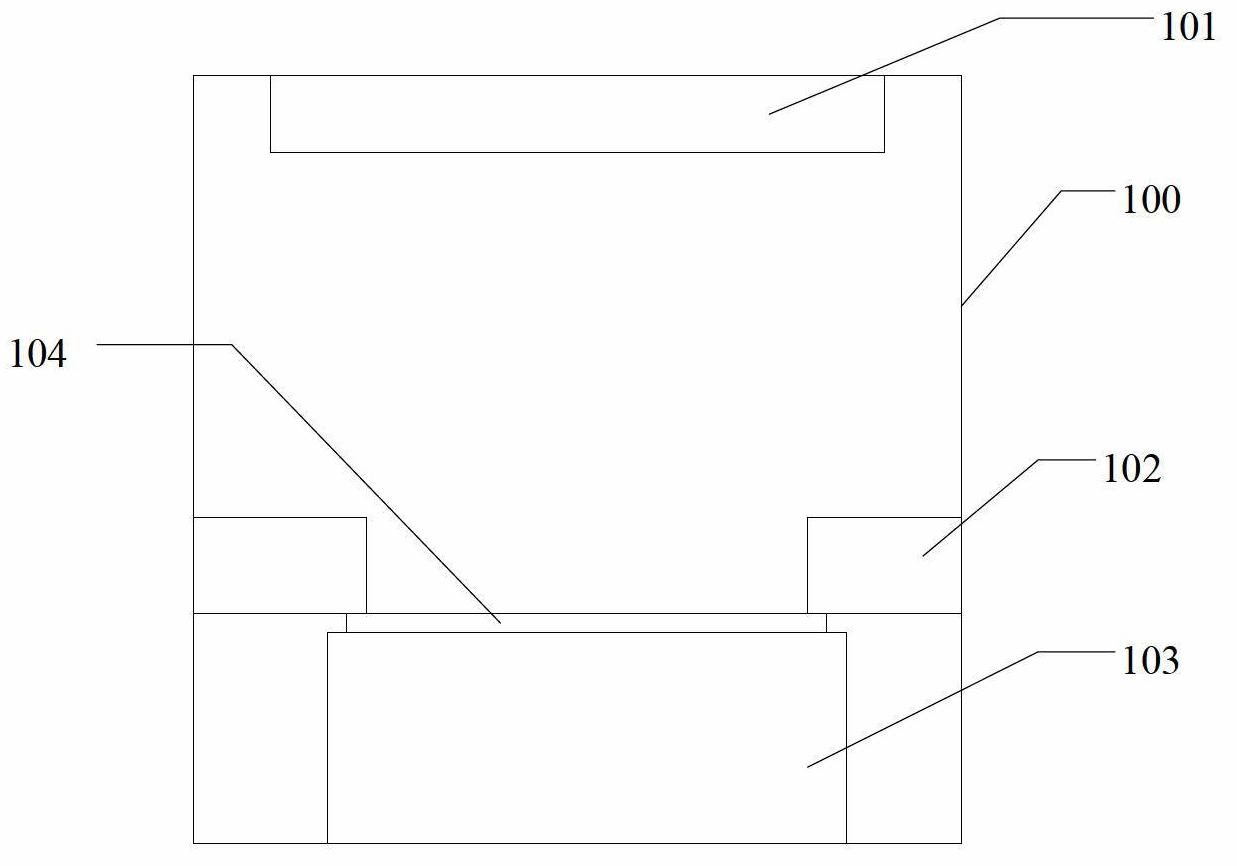

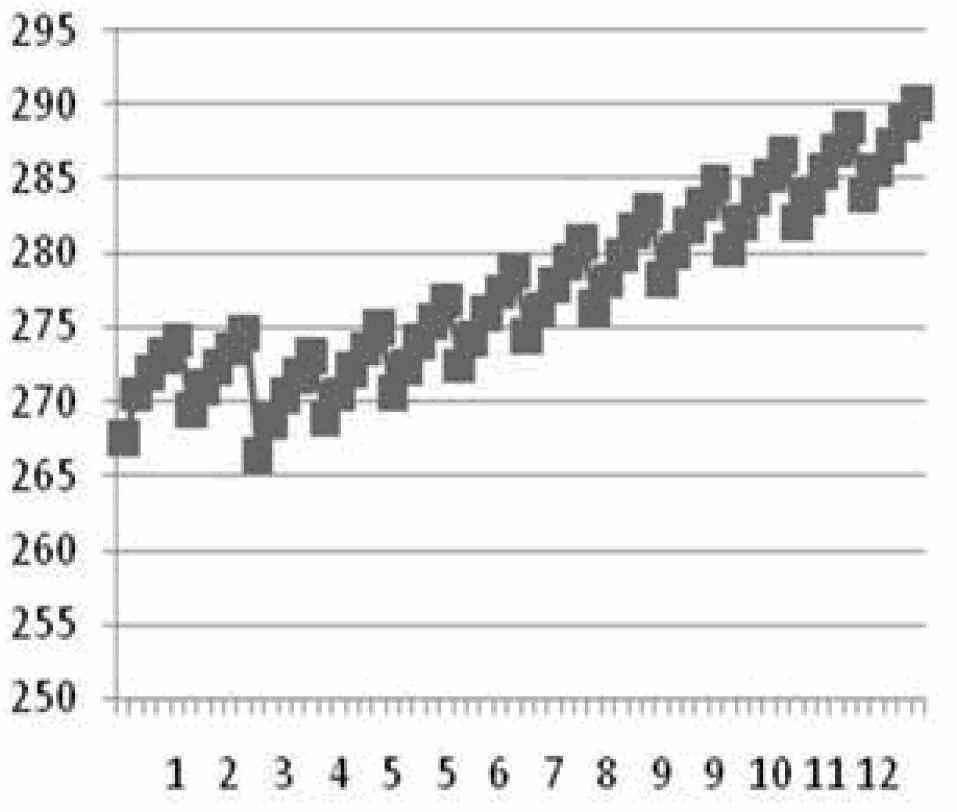

[0027] figure 1 It is a cross-sectional view of a physical vapor deposition equipment process chamber in the prior art. figure 2 yes figure 1 The temperature change diagram of the wafer support base when the physical vapor deposition equipment deposits a 40,000 angstrom aluminum metal layer.

[0028] Please refer to figure 1 , the top of the process chamber 100 is provided with a target 101, the bottom of the process chamber 100 is provided with a wafer carrying base 103, a wafer 104 is placed on the wafer carrying base 103, and the wafer 104 is fixed in the process chamber The wafer fixing ring 102 on the side wall of the body 100 is fixed on the wafer supporting base 103 . When the physical vapor deposition equipment starts to deposit, the plasma (not shown in the figure) bombar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com