Sand-preventive sealing device of submersible electric pump

A technology of submersible electric pumps and sealing devices, which is applied to parts of pumping devices for elastic fluids, pump elements, variable capacity pump parts, etc., to achieve the effects of protecting safe operation, protecting normal operation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

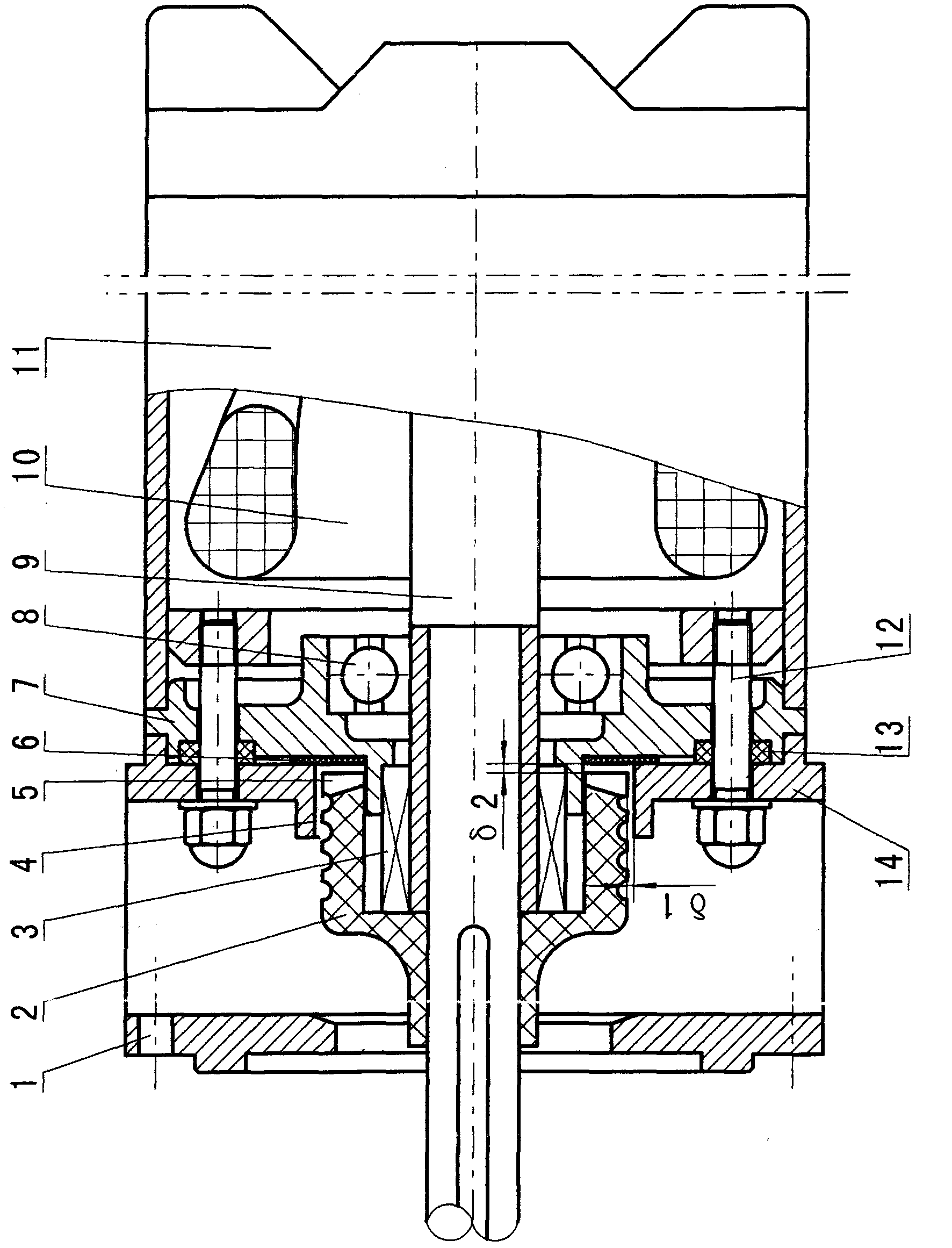

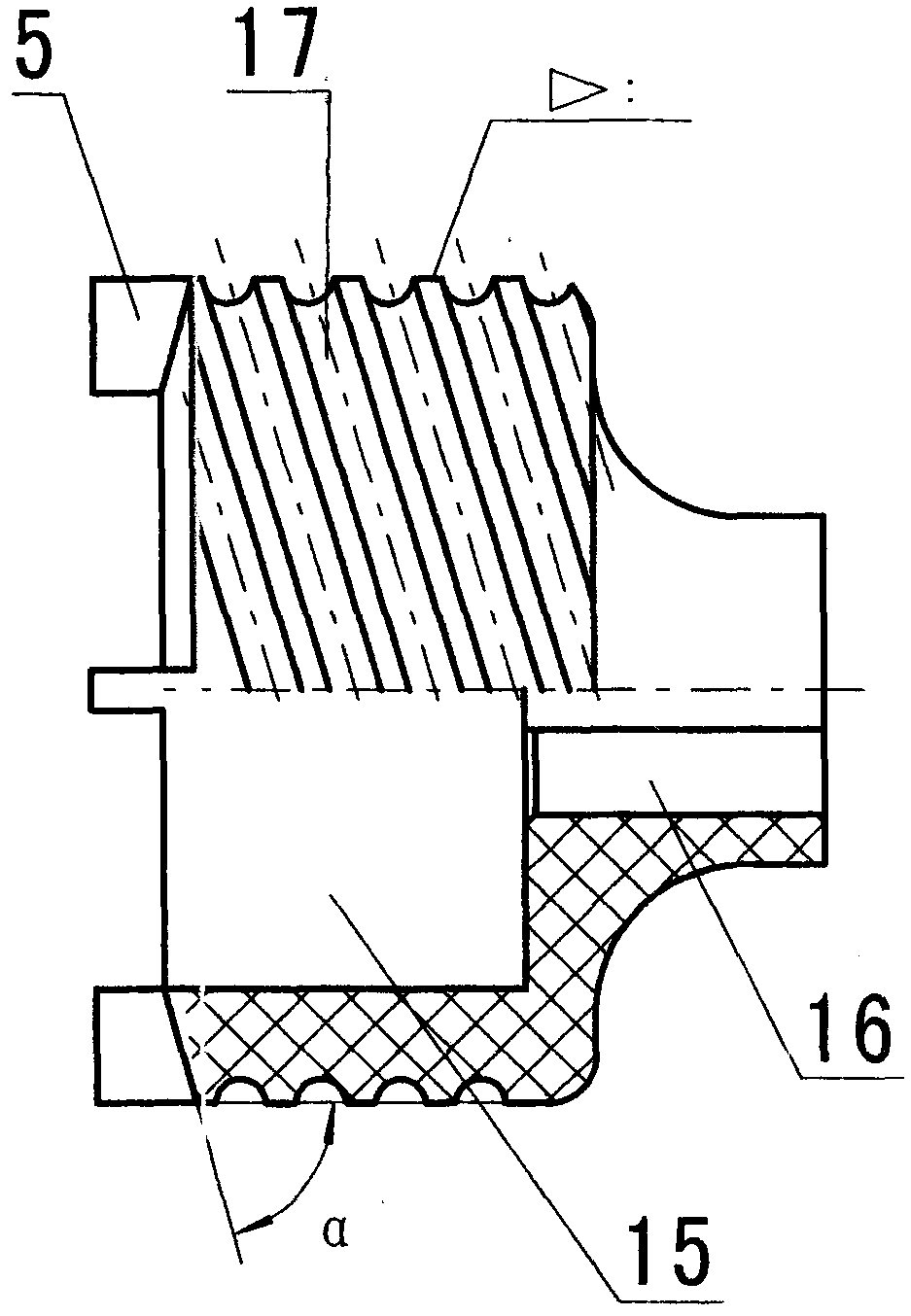

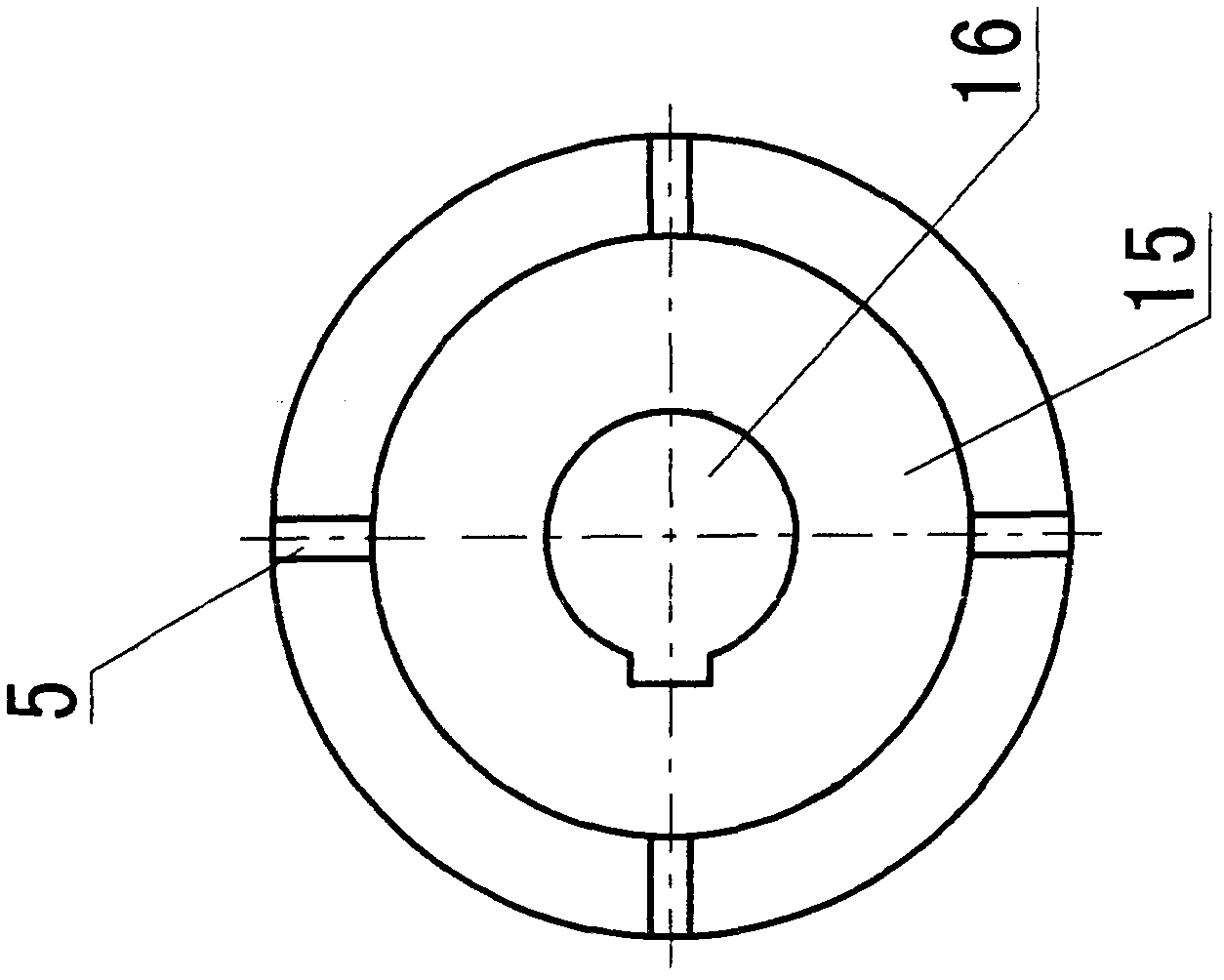

[0019] see figure 1 , a submersible electric pump sand prevention sealing device, consisting of a spiral sand throwing ring 2, a mechanical seal 3, a sand discharge ring 4, a sand throwing blade 5, a rubber pad 6, a bearing seat 7, a bearing 8, a motor rotor shaft 9, and a motor sealing chamber 10. The motor casing 11, the connecting screw 12, the connecting screw sealing ring 13 and the connecting flange 14 are composed. The spiral sand throwing ring 2 is set on the motor rotor shaft 9 through a key, and the mechanical seal 3 is set on the motor rotor shaft 9 through a bushing. , the mechanical seal 3 is located in the mechanical seal installation cavity 15 of the spiral sand throwing ring 2 and on the side of the stop of the bearing seat 7, and a rubber pad 6 is sandwiched between the connecting flange 14 and the bearing seat 7, and the connecting flange 14 The sand discharge ring 4 is connected to the inner ring, and the connecting screw 12 connects the connecting flange 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com