Test chuck for water pressure of free body of dry powder bottle cylinder body

A hydrostatic test and chuck technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as non-conformance, and achieve the effects of high test quality, high test efficiency and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

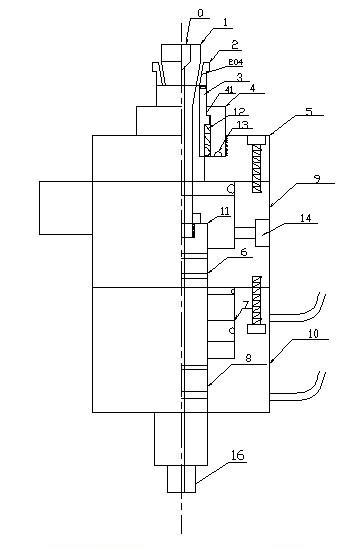

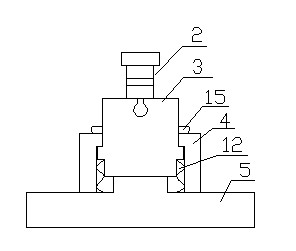

[0022] Examples:

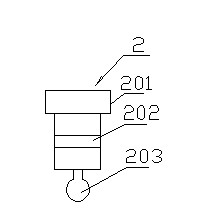

[0023] Such as figure 1 , 2 The free-body hydraulic test chuck for the dry powder bottle cylinder is provided with a clamp, a water drain box, and an oil cylinder; the clamp includes a chuck pull rod 1 with a through hole in the middle, a locking sleeve 3 outside the chuck pull rod, and a locking sleeve 3 A locking guide sleeve 4 is sheathed on the outside, and three locking pieces 2 are movably connected to the locking sleeve. The cylinder includes a cylinder body 10, in which a piston 7 and a cylinder shaft 11 with a through hole in the middle are installed. Equipped with a sealing ring and a dust ring 8 for sealing. The water discharge block 9 is provided with water inlet and outlet holes 14 with two layers of sealing rings 6 inside; the water discharge block 9 is equipped with a cover head 5, and a connecting hole is arranged in the middle of the cover head. The locking guide sleeve 4 is used for passing through the connection hole. The screw thread is con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap