Matching fiber grating acoustic emission sensing system with temperature compensation function

A temperature compensation, fiber Bragg grating technology, which is used in material analysis using acoustic wave emission technology, using wave/particle radiation, and measuring ultrasonic/sonic/infrasonic waves, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

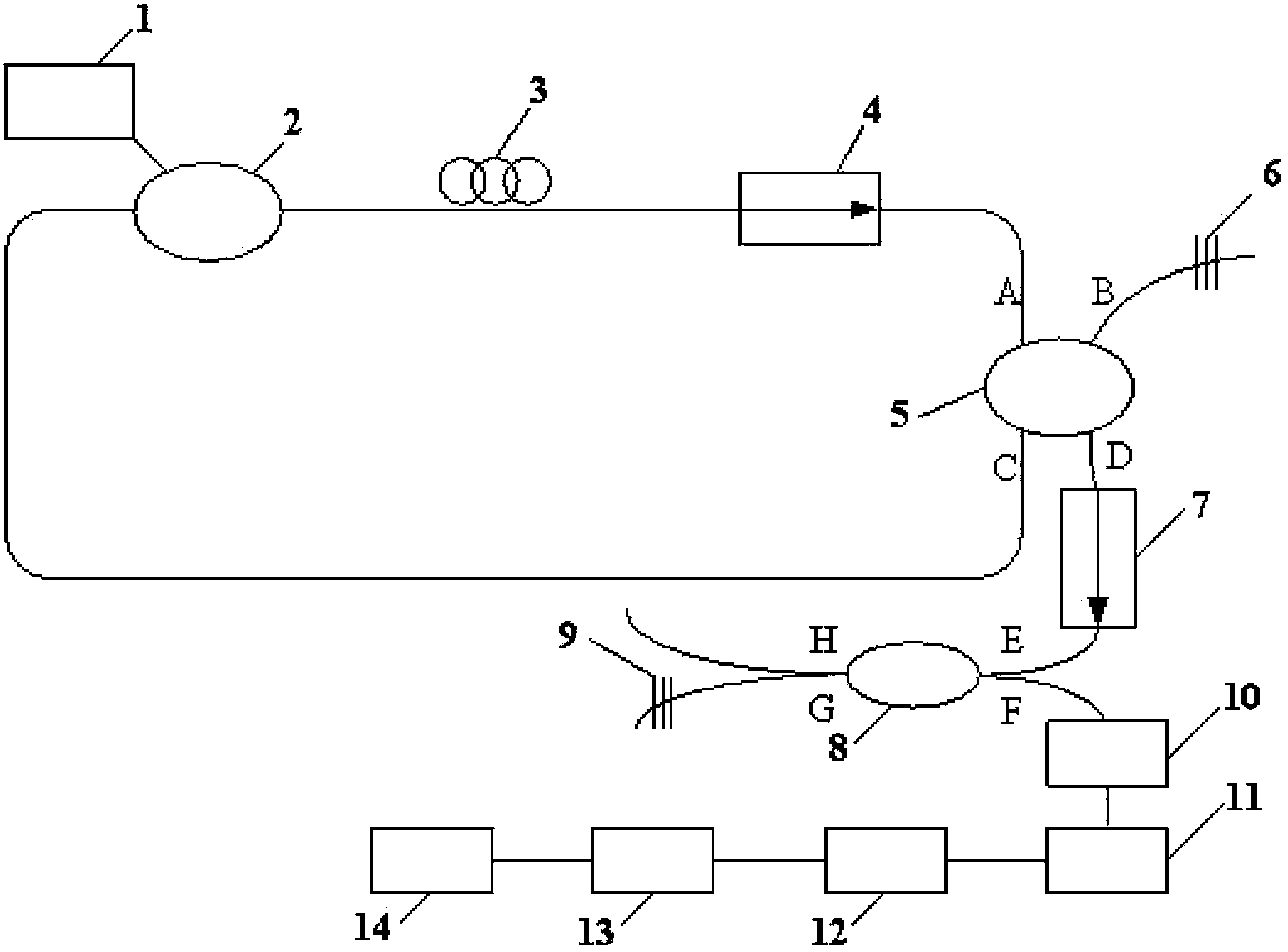

[0017] Such as figure 1 As shown, the matching fiber grating acoustic emission sensing system with temperature compensation of the present invention includes: a pump source 1, an optical wavelength division multiplexer 2, an erbium-doped optical fiber 3, a first optical isolator 4, a first Fiber coupler 5, first fiber Bragg grating 6, second optical isolator 7, second fiber coupler 8, second fiber Bragg grating 9, photodetection circuit 10, preamplification circuit 11, analog-to-digital conversion circuit 12, FPGA13, computer 14; Wherein, the A port of the first optical fiber coupler 5 is connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com