Touch sensing element and conductive electrode structure

A technology of conductive electrodes and inductive elements, which is applied in the direction of electrical digital data processing, instruments, and input/output processes of data processing, etc., and can solve problems such as open circuit, inability to actuate, and large impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

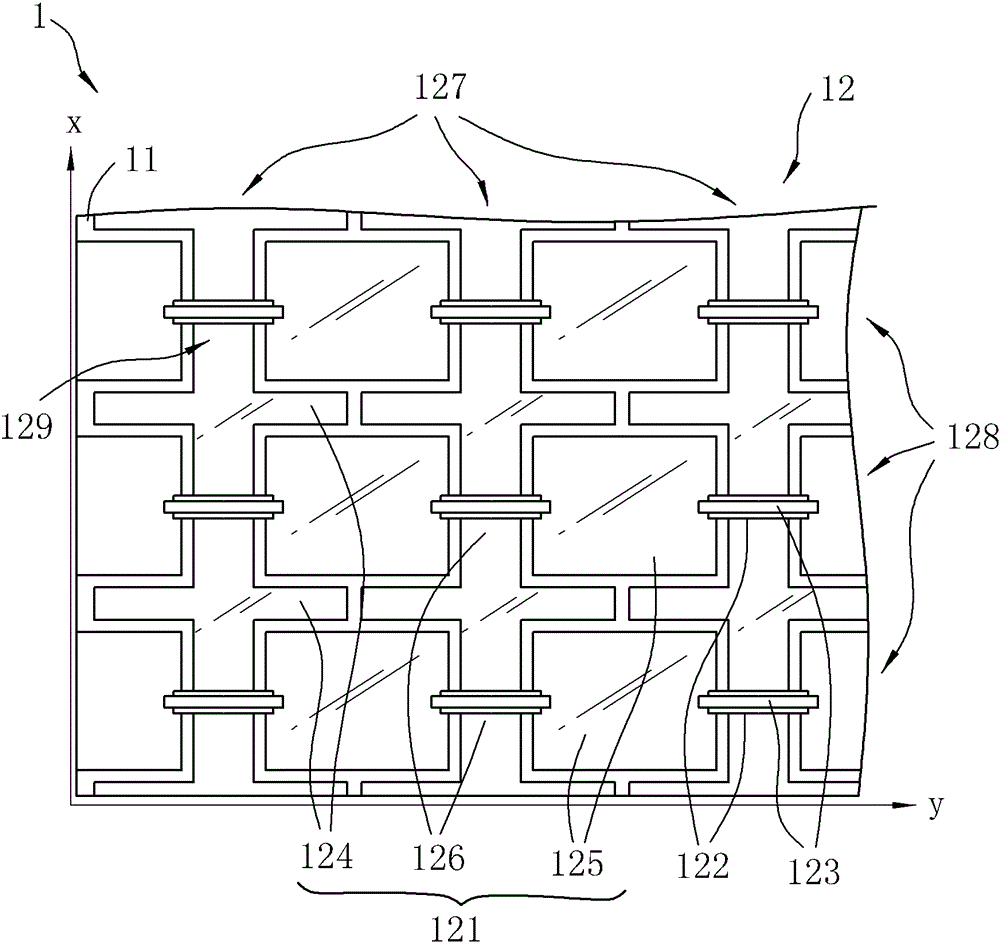

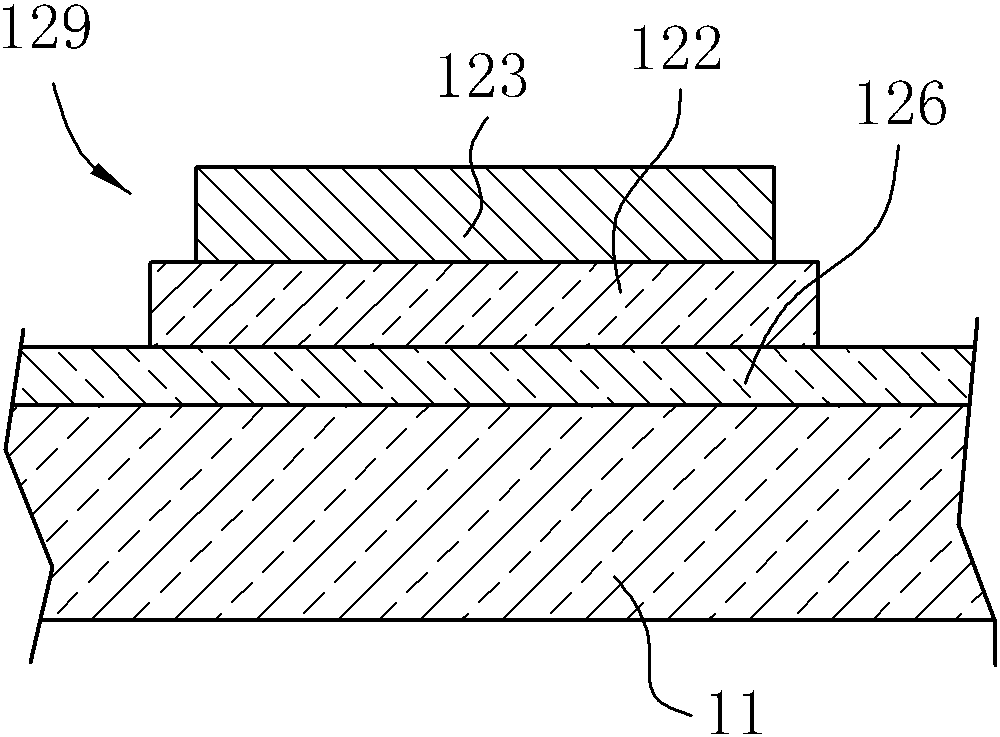

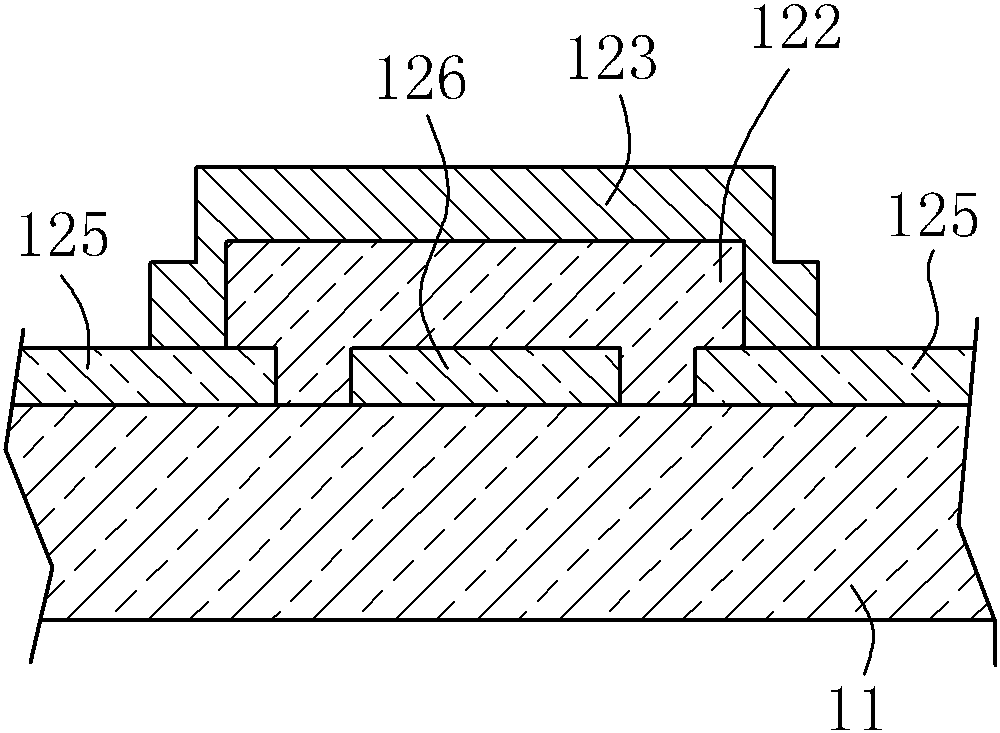

[0048] refer to Figure 4 , refer to Figure 5 , the first preferred embodiment of the present invention is illustrated by taking a capacitive touch sensing element 2 as an example, which includes a substrate 21 and a touch sensing circuit 22 disposed on the substrate 21 . The touch sensing circuit 22 includes a conductive block structure 221 , a conductive electrode structure 222 , and a plurality of dielectric films 223 .

[0049] The substrate 21 can be made of acrylic, polycarbonate, polyethylene, plastic, glass, and a combination thereof.

[0050] The conductive block structure 221 is made of conductive material and disposed on the substrate 21, and includes a plurality of first conductive blocks 224 arranged in an array and spaced apart from each other, and a plurality of second conductive blocks arranged in an array and spaced apart from each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com