Three degree-of-freedom parallel mechanism tea screening machine

A technology of screening machine and degree of freedom, which is applied in the direction of screening, solid separation, grid, etc., can solve the problems of shortening the screening time and insufficient vibration freedom, and achieve shortening screening time, convenient control and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

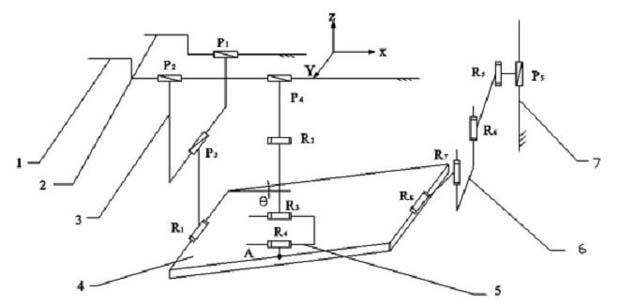

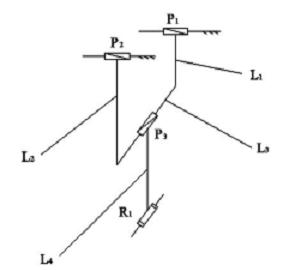

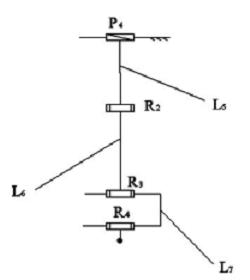

[0014] Such as figure 1 As shown, a three-degree-of-freedom parallel mechanism tea sieving machine consists of a horizontal slide rail 1, a horizontal slide rail 2, a Y-direction vibrating chain 3, a screen frame 4, an X-direction vibrating chain 5, a vibrating chain 6 rotating around the X axis, and a It consists of 7 vertical slide rails. Among them: one end of the Y-direction vibration chain 3 is installed on the horizontal slide rail 1 and the horizontal slide rail 2, and the other end is connected with the screen frame 4; one end of the X-direction vibration chain 5 is installed on the horizontal slide rail 1, and the other end is fixed to the screen frame 4; One end of the vibrating chain that rotates around the X axis is installed on the vertical slide rail 7 and the other end is fixed on the screen frame 4; the vibrating mechanism is composed of thr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap