Positioning fixture for comprehensive metal machining for differential gear blank of differential mechanism

A half-shaft gear and positioning fixture technology is applied in the field of gear metal processing to achieve the effects of improving product quality, simplifying processes, and solving geometric tolerance accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

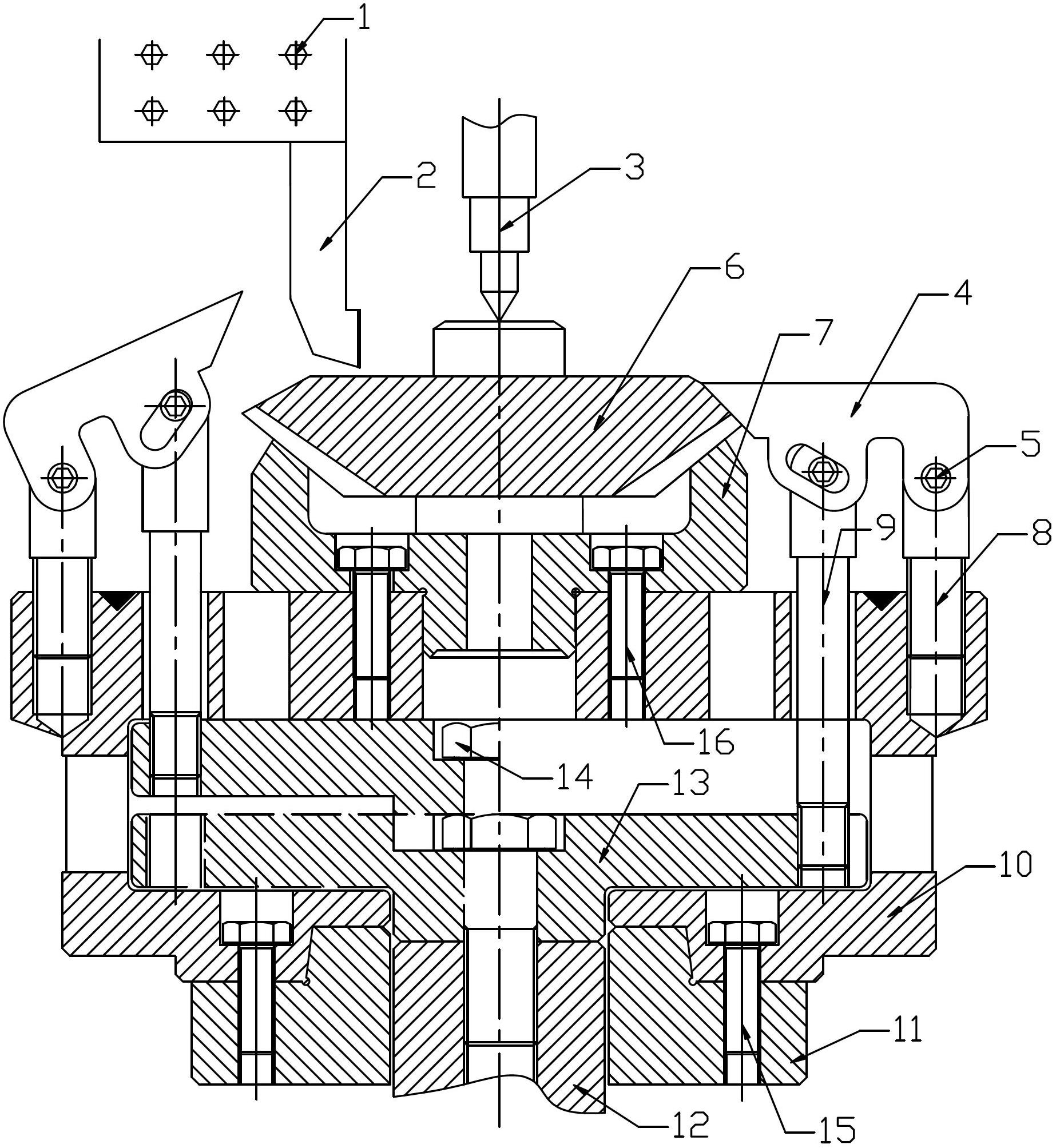

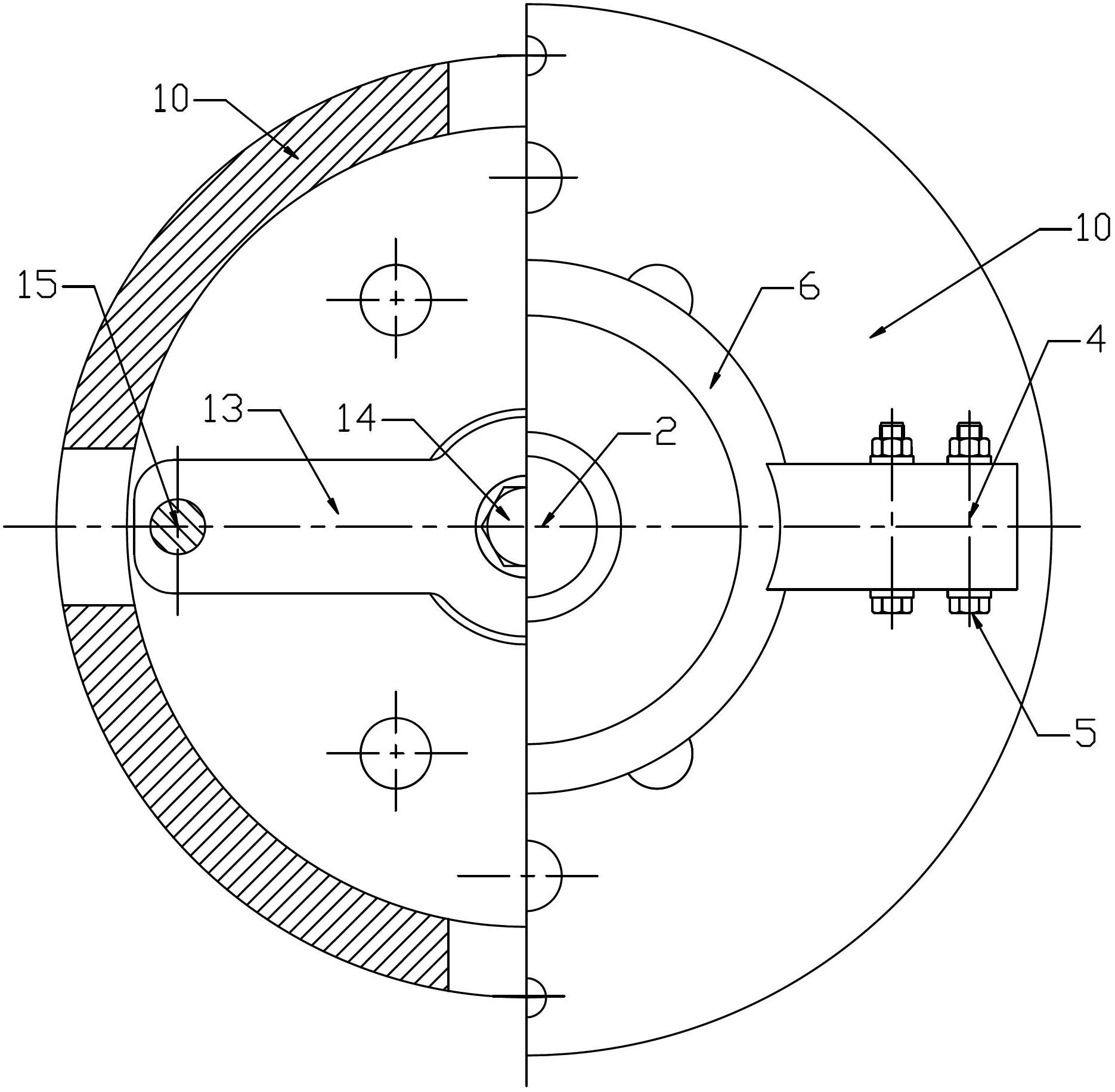

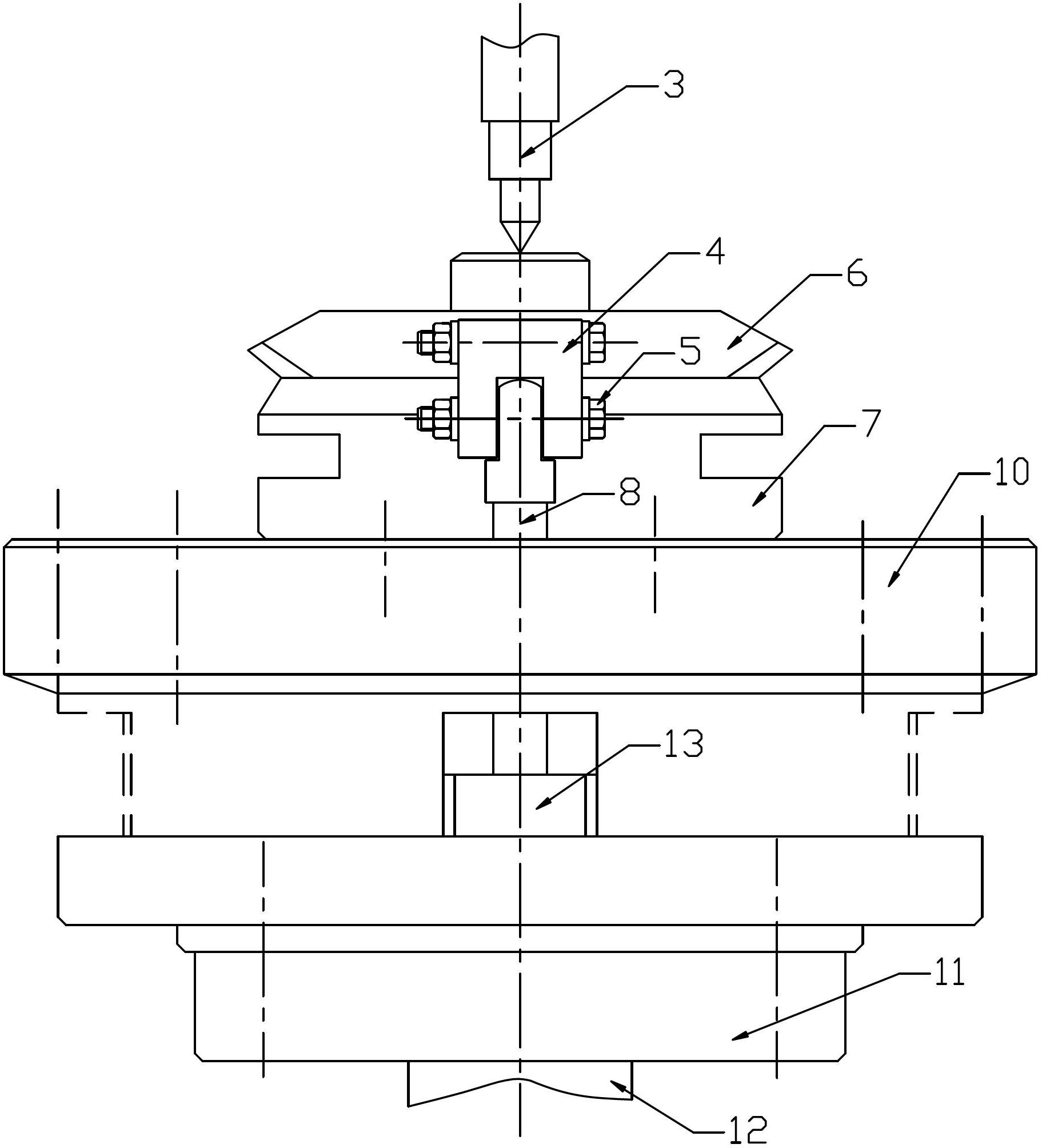

[0027] Such as Figure 1~3 As shown, a positioning fixture for comprehensive metal processing of differential half-shaft gear blanks. The positioning fixture includes a fixture seat 10 on which a positioning ring gear for supporting the half-shaft gear blank 6 is fixed. 7. The clamp base 10 is also provided with a clamping device that cooperates with the positioning ring gear 7 to fix the semi-shaft gear blank 6.

[0028] There are many implementation schemes for the positioning ring gear 7, as long as it can support the semi-shaft gear blank 6 well, as the preferred scheme of the present invention, such as figure 1 As shown, the upper end of the positioning ring gear 7 is provided with a positioning tooth groove that meshes with the tooth profile of the semi-shaft gear blank 6, and the lower end of the positioning ring gear 7 is provided with a positioning mandrel; the upper end of the clamp seat 10 is provided There is a positioning hole matched with the positioning mandrel of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap