Structure-controllable cellulose graft copolymer and montmorillonite composite and preparation method thereof

A technology of cellulose grafting and composite materials, applied in the field of polymer nanocomposite new materials, to achieve the effects of easy operation, mild reaction conditions, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

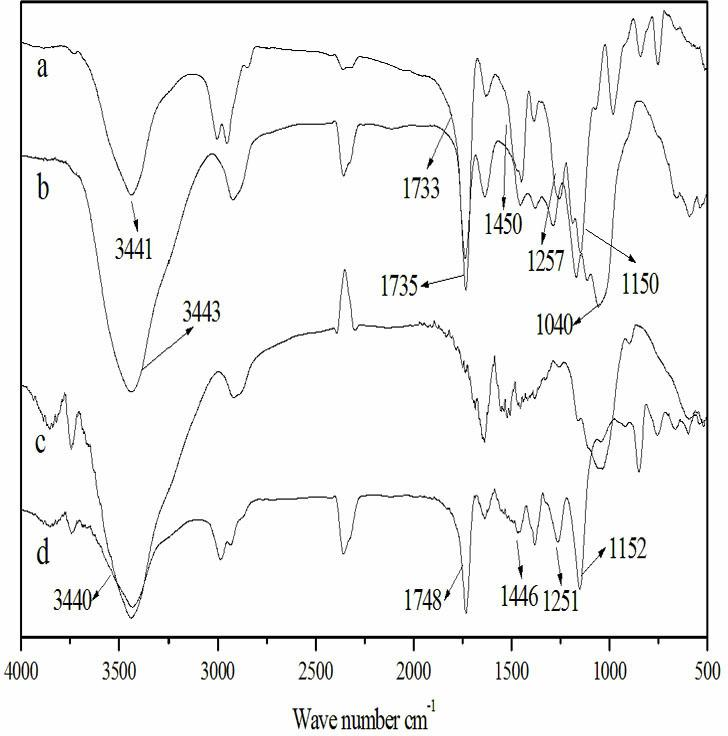

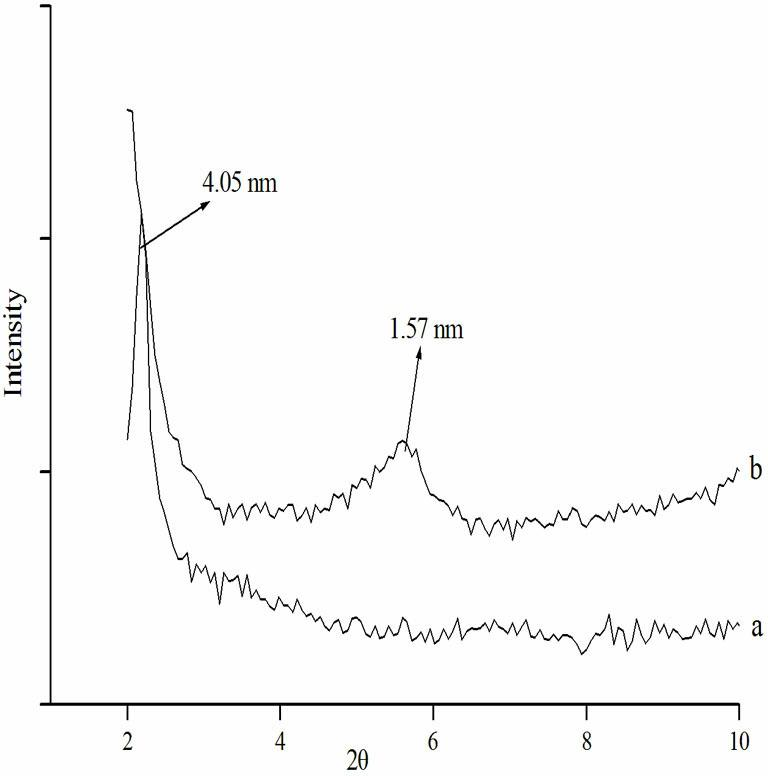

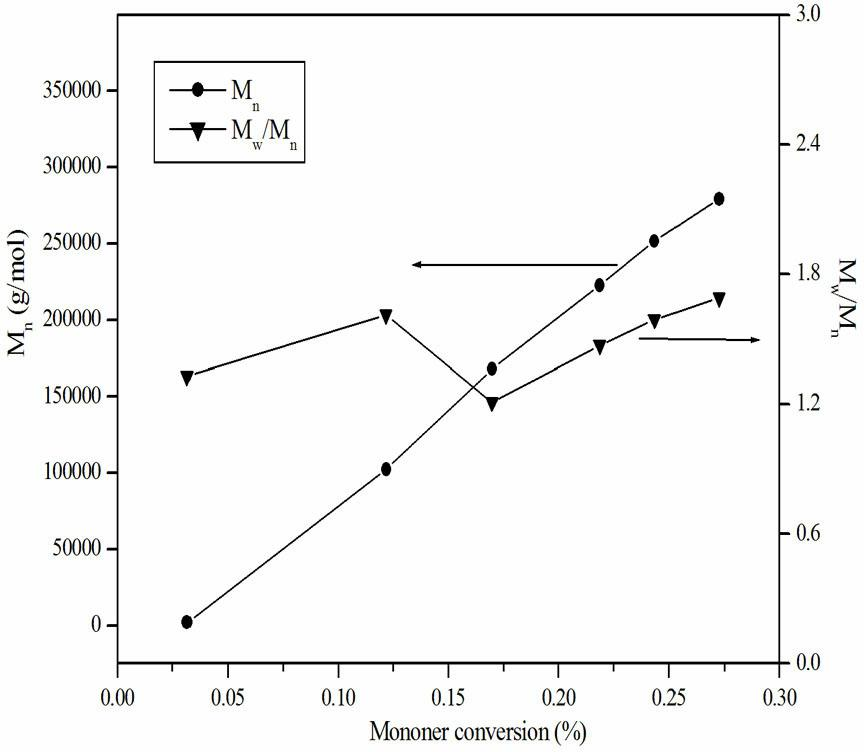

[0035]0.2 g of bamboo fiber was dissolved in 10.0 g of 1-allyl-3-methylimidazolium chloride ionic liquid to obtain a cellulose ionic liquid solution with a concentration of 2%, and 1.7 g of 2-chloroacetyl chloride was added dropwise. After stirring for 10 h, a cellulose macroinitiator with a degree of substitution of 2.4 was prepared. Take 0.4 g of the above-mentioned cellulose macromolecular initiator and dissolve it in tetrahydrofuran, add 14.8 g of methyl methacrylate containing 1.4% by weight of montmorillonite, and 2.8 g of N,N-bipyridine successively under the protection of nitrogen. Under the bath, carry out 3 times of vacuum-filling nitrogen cycle, under N 2 Add 0.85 g molar ratio of CuBr under protection, then perform 3 times vacuum-nitrogen cycle, and then react in 80 °C oil bath for 0.5 h to obtain cellulose graft copolymer / montmorillonite composite material, macromolecular initiator The molar ratio of catalyst, ligand and polymerizable monomer is 1:1:8:50. The gr...

Embodiment 2

[0037] 1 g cotton fiber was dissolved in 10.0 g 1-butyl-3-methylimidazolium chloride ionic liquid to obtain a cellulose ionic liquid solution with a concentration of 10%, and 6.7 g of 2-bromopropionyl bromide was added dropwise, at 70°C The reaction was stirred for 2 h to prepare a cellulose macroinitiator with a degree of substitution of 1.5. Take 0.2 g of the above-mentioned cellulose macromolecular initiator and dissolve it in DMF, add 24.1 g of hydroxyethyl methacrylate containing 1% by weight of montmorillonite and 0.21 g of tetramethylethylenediamine successively under the protection of nitrogen. Under the bath, carry out 3 times of vacuum-filling nitrogen cycle, under N 2 Under protection, 0.18 g molar ratio of CuCl was added for 3 times of vacuum-filling nitrogen cycle, and then reacted in an oil bath at 60°C for 8 h to obtain a cellulose graft copolymer / montmorillonite composite material, a macromolecular initiator, and a catalyst The molar ratio of , ligand and poly...

Embodiment 3

[0039] 3 g of wood pulp fibers were dissolved in 10.0 g of 1-allyl-3-methylimidazolium chloride ionic liquid to obtain a 30% cellulose ionic liquid solution, and 2.4 g of 2-chloropropionyl chloride was added dropwise at 25°C Stirring and reacting for 96 h, a cellulose macroinitiator with a degree of substitution of 1.2 was prepared. Take 0.1 g of the above-mentioned cellulose macromolecular initiator and dissolve it in DMSO, and add 9.5 g of tert-butyl acrylate containing 1.8% by weight of montmorillonite and 0.93 g of N,N-bipyridine successively under nitrogen protection. Carry out 3 times of vacuum-filling nitrogen cycle under N 2 Under protection, 0.21 g molar ratio of CuBr was added for 3 times of vacuum-nitrogen cycle, and then reacted in an oil bath at 90°C for 6 h to obtain a cellulose graft copolymer / montmorillonite composite material, a macromolecular initiator, and a catalyst The molar ratio of , ligand and polymerizable monomer is 1:2:8:100. The grafting rate of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com