Gas adsorption and concentration device

A concentration device and gas adsorption technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of insufficient sealing effect and insufficient rubber elasticity, so as to ensure air tightness and high degree of freedom , little effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

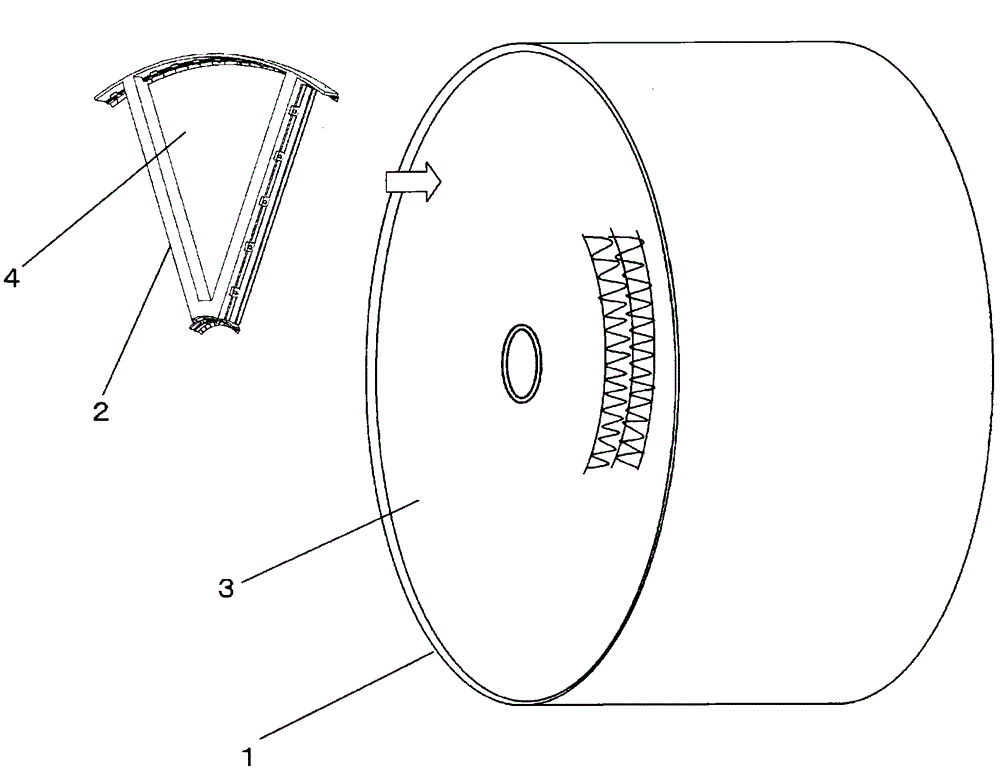

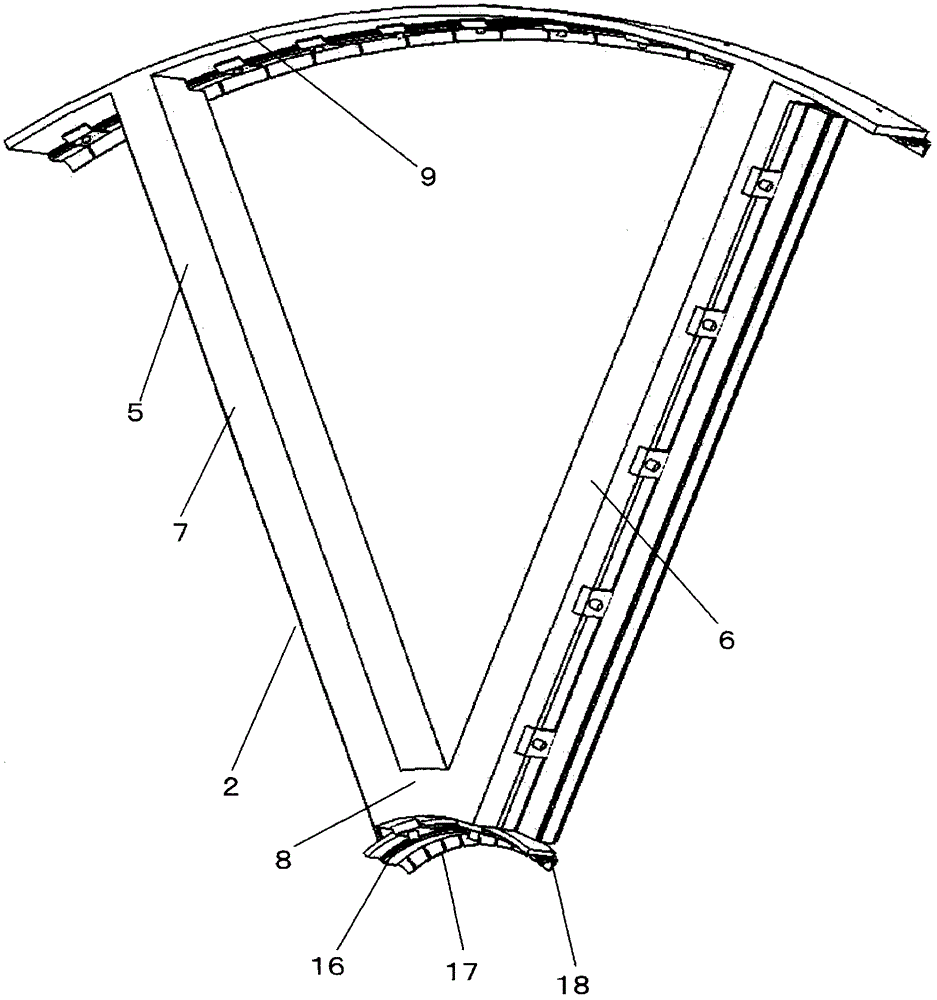

[0041] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a perspective view of the disassembled state of the organic solvent adsorption concentration device. 1 is a honeycomb runner, and an organic solvent adsorbent such as a hydrophobic zeolite is supported on a nonflammable cloth made of ceramics. 2 is the seal of the desorption zone 4 , thereby dividing the honeycomb runner 1 into the adsorption zone 3 and the desorption zone 4 .

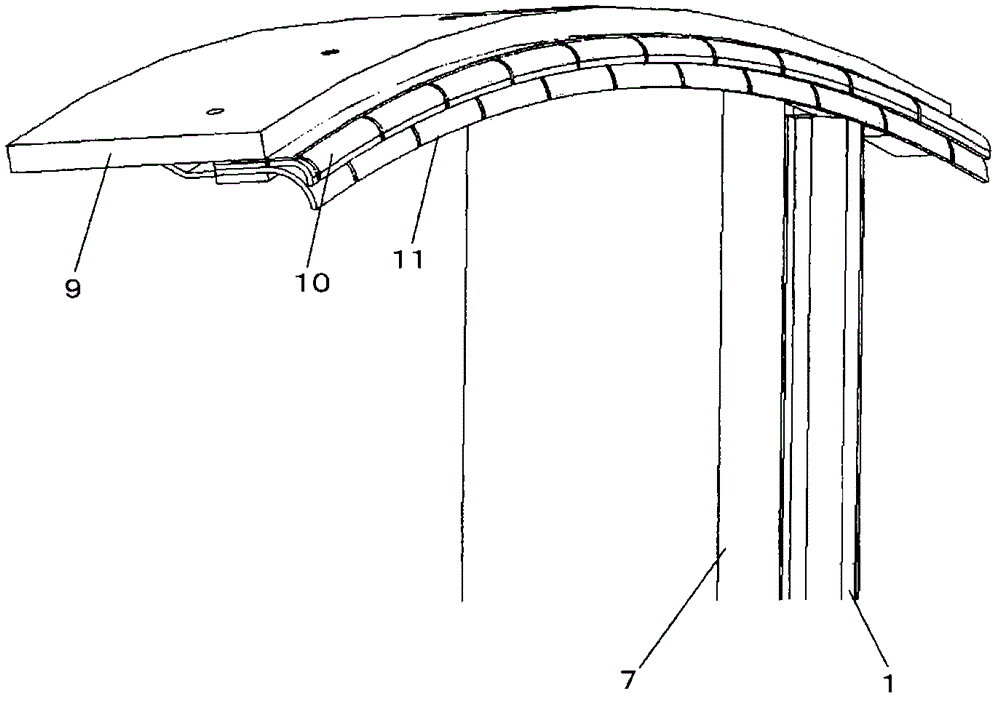

[0042] The sealing member 2 is roughly fan-shaped, and 5 is a sealing body, which is made of a combination of a square tube such as stainless steel and a plate. In detail, the sealing body 5 includes: a pair of radial seals 6, 7 formed of a square tube; an inner peripheral seal 8; an outer peripheral seal 9 formed in an arc shape and formed of a plate.

[0043] Two outer peripheral seal sheets 10 , 11 are attached to the outer peripheral seal 9 in an overlapping state. exist Figure 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com