A kind of acyl-containing complexing surfactant and its synthesis method

A technique for surfactants and synthetic methods, which is applied in chemical instruments and methods, preparation of carboxylic acid amides, preparation of organic compounds, etc., can solve problems such as high safety requirements, and achieve simple synthesis methods, low irritation, and equipment requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

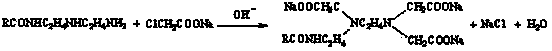

Method used

Image

Examples

Embodiment 1

[0024] Add 38.15g of diethylenetriamine and 1.285g of sodium methoxide into a four-necked round-bottomed flask, raise the temperature to 120°C while stirring, add 20.0g of methyl laurate dropwise, start vacuuming, maintain the temperature at 120°C, and the vacuum degree at 0.06MPa , after stirring and reacting for 5 hours, wash with water until pH=7~8 of the lotion, and dry the intermediate.

[0025] Add 10.0g of isopropanol to the above-mentioned four-necked round-bottomed flask, then add 10.05g of N-acyldiethylenetriamine, stir and raise the temperature to 80°C, and add dropwise a solution of 12.24g of sodium chloroacetate dissolved in 20.0g of water, the reaction process Maintain the pH of the solution at 8.5, and obtain a pale yellow product.

Embodiment 2

[0027] Add 48.13g of diethylenetriamine and 1.285g of sodium methoxide into a four-necked round-bottomed flask, raise the temperature to 120°C while stirring, add 20.00g of methyl laurate dropwise, start vacuuming, maintain the temperature at 120°C, and the vacuum degree at 0.06MPa , After stirring and reacting for 5 hours, the excess diethylenetriamine was distilled off with a decompression device to obtain the intermediate N-acyl diethylenetriamine.

[0028] Add 10.0 g of isopropanol to the above-mentioned four-necked round-bottomed flask, then add 10.05 g of N-acyl diethylenetriamine, stir and raise the temperature to 75 ° C, and dropwise add a solution of 12.27 g of sodium chloroacetate dissolved in 20.0 g of water, the reaction process Maintain the pH of the solution at 8.5, and react for 8 hours to obtain a light yellow product.

Embodiment 3

[0030] Add 77.76g of diethylenetriamine and 1.35g of sodium methoxide into a four-necked round-bottomed flask, raise the temperature to 120°C while stirring, add 20.00g of methyl laurate dropwise, start vacuuming, maintain the temperature at 122°C, and the vacuum degree at 0.05MPa , After stirring and reacting for 5 hours, the excess diethylenetriamine was distilled off with a vacuum distillation device to obtain an intermediate.

[0031] Add 10.0g of isopropanol to the above-mentioned four-necked round-bottomed flask, then add 10.01g of N-acyldiethylenetriamine, stir and raise the temperature to 75°C, add dropwise a solution of 12.24g of sodium chloroacetate dissolved in 20.0g of water, the reaction process Maintain the pH of the solution at 8.5, and react for 8 hours to obtain a light yellow product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com