Composite proton exchange membrane for high-temperature fuel cell and preparation method of composite proton exchange membrane

A high-temperature fuel cell and proton exchange membrane technology, which is applied to fuel cells, fuel cell parts, battery pack parts, etc., can solve the problems of unbalanced effect and unsatisfactory battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

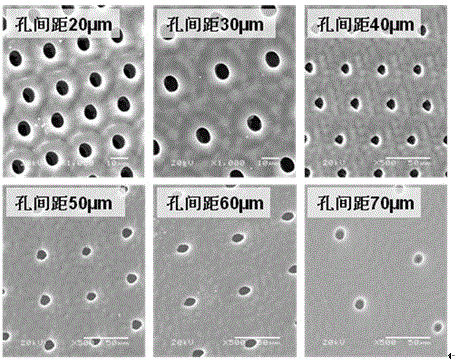

[0024] Take a polyimide film with a thickness of 20 μm, and use a UV laser to etch ordered straight-through holes with a diameter of 5-10 μm on the surface, with a hole spacing of 20-70 μm, and use the above acid-base (1M potassium hydroxide and 1M hydrochloric acid) method for surface treatment to obtain hydrophilic properties. Place the hydrophilic polyimide matrix film in a 5% perfluorosulfonic acid resin solution (Nafion DE520, EW value 1000, solvent is isopropanol and water at a mass ratio of 10:9) for 10 minutes , then take it out and hang it to dry at room temperature, then put it in a vacuum drying oven, adjust the temperature to 150°C, heat treatment for 60 seconds, repeat the above dipping treatment steps until the thickness of the composite film reaches 25±2μm; dip the prepared composite film in Remove surface activity in isopropanol solution for 5 minutes, soak in 80°C deionized water for 10 minutes, then take it out and put it in a vacuum drying oven for heat trea...

Embodiment 2

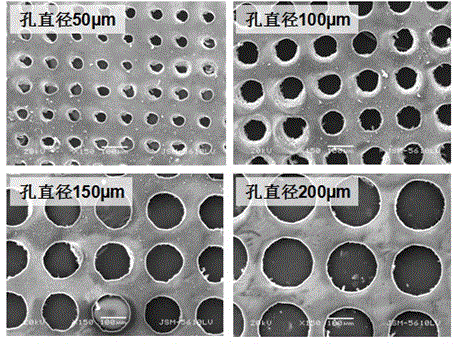

[0027] Take a polyimide film with a thickness of 20 μm, and use a UV laser to etch through holes with a diameter of 50-200 μm on the surface, keeping the hole spacing unchanged, and use the above acid-base (1M potassium hydroxide and 1M hydrochloric acid) method for surface treatment to obtain Hydrophilic properties. Place the hydrophilic polyimide matrix film in a 5% perfluorosulfonic acid resin solution (Nafion DE520, EW value 1000, solvent is isopropanol and water at a mass ratio of 10:9) for 10 minutes , then take it out and hang it to dry at room temperature, then put it in a vacuum drying oven, adjust the temperature to 150°C, heat treatment for 60 seconds, repeat the above dipping treatment steps until the thickness of the composite film reaches 25±2μm; dip the prepared composite film in Remove surface activity in isopropanol solution for 5 minutes, soak in 80°C deionized water for 10 minutes, then take it out and put it in a vacuum drying oven for heat treatment at 120...

Embodiment 3

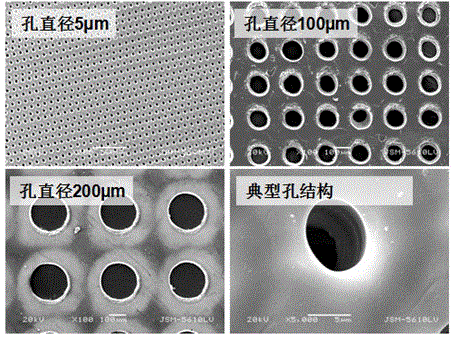

[0030] Take a polyimide film with a thickness of 20 μm, and use a UV laser to etch a straight-through hole with a diameter of 5-200 μm on the surface, and use the above acid-base (1M potassium hydroxide and 1M hydrochloric acid) method for surface treatment to obtain hydrophilic properties. Place the hydrophilic polyimide matrix film in a 5% perfluorosulfonic acid resin solution (Nafion DE520, EW value 1000, solvent is isopropanol and water at a mass ratio of 10:9) for 10 minutes , then take it out and hang it to dry at room temperature, then put it in a vacuum drying oven, adjust the temperature to 150°C, heat treatment for 60 seconds, repeat the above dipping treatment steps until the thickness of the composite film reaches 25±2μm; dip the prepared composite film in Remove surface activity in isopropanol solution for 5 minutes, soak in 80°C deionized water for 10 minutes, then take it out and put it in a vacuum drying oven for heat treatment at 120°C for 40 seconds to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com