Automatic material taking and feeding mechanical hand for multi-station transmission die stamping

A technology of stamping processing and transfer die, which is applied in the field of manipulators, can solve problems such as high input cost, insufficient production efficiency, and hidden dangers of work-related injuries, and achieve the effects of reducing input costs, improving production efficiency, and avoiding work-related accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] detailed description

[0015] The present invention will be further described below in conjunction with the drawings and embodiments.

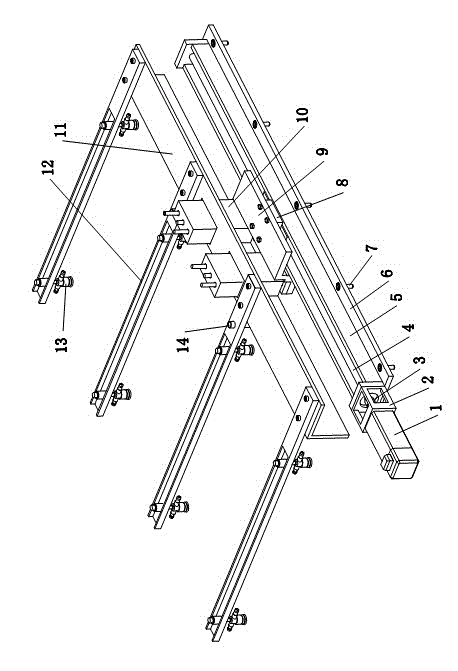

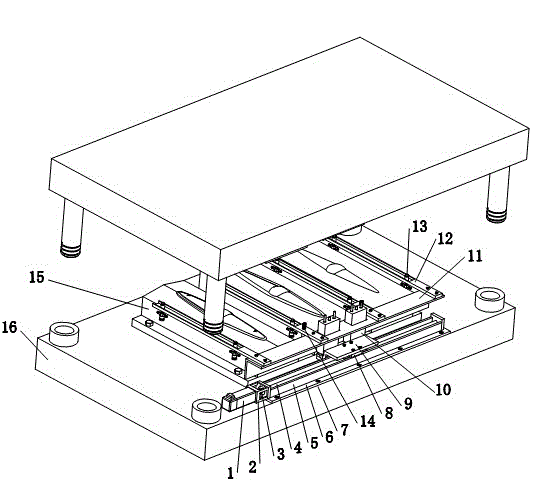

[0016] Such as Figure 1 to 2 As shown, a multi-station transfer die stamping process automatic feeding and feeding manipulator includes a fixed plate 6 installed on the lower template 16. The feature of the present invention is that it also includes a transverse feeding device, a vertical feeding and unwinding device, a beam 11, and two The above cantilevers 12 and four or more vacuum suction cups 13 are provided with four cantilever arms 12 and eight vacuum suction cups 13 in this embodiment. The number of cantilevers 12 and vacuum suction cups 13 can also be set according to actual needs; The feeding device is installed on the fixed plate 6. The vertical picking and unloading device cooperates with the transverse feeding device and can be driven by the transverse feeding device to move horizontally; the beam 11 is installed on the verti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap