High-tightness buttress thread sleeve joint

A threaded casing and connecting joint technology, which is applied in the field of oil well pipe threaded joints, can solve the problems of weak torque resistance, low connection strength, poor sealing performance, etc., and achieve the effect of increasing the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

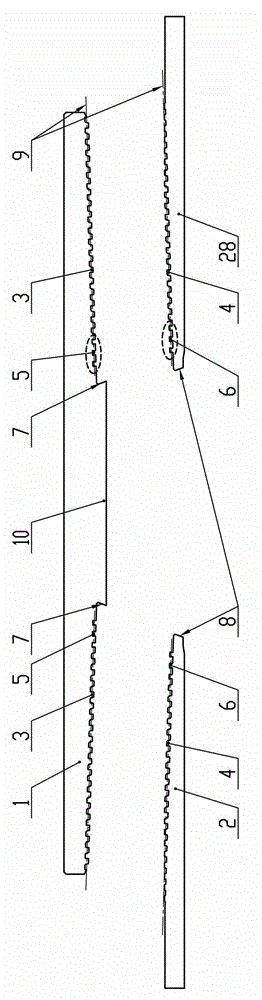

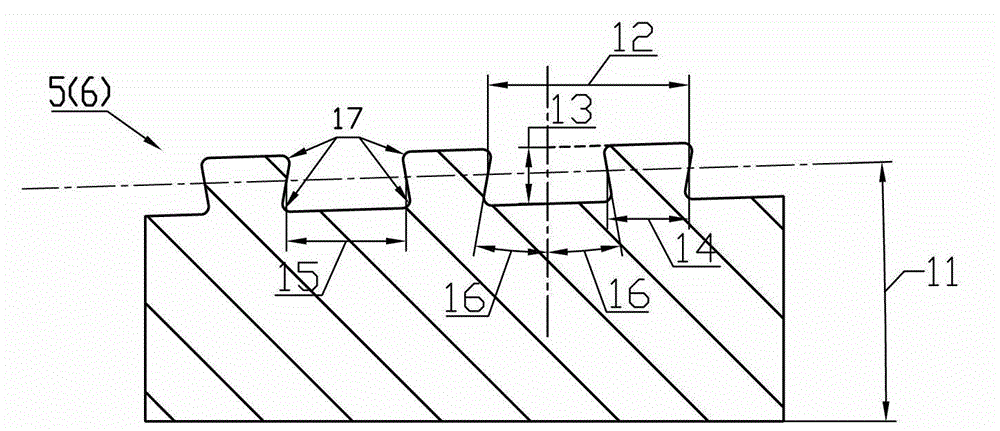

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Figure 1~Figure 5 Among them, including coupling 1, pipe body 2, partial trapezoidal internal thread 3, partial trapezoidal external thread 4, wedge-shaped internal thread 5, wedge-shaped external thread 6, inner sealing structure 7, outer sealing structure 8, middle diameter line 9, inner platform Shoulder cylinder surface 10, taper 11, pitch 12, tooth height 13, tooth width 14, tooth groove width 15, flank angle 16, tooth arc 17, inner conical surface 18, outer conical surface 19, inner platform Shoulder thickness 20, outer shoulder thickness 21, inner shoulder chamfer 22, outer shoulder chamfer 23, inner vertex arc 24, outer vertex arc 25, inner cylindrical surface 26, transition cone surface 27, pipe body 28, etc. .

[0020] Such as figure 1 , figure 2 As shown, the present invention is a high-tight trapezoidal thread casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com