Method for rapidly detecting leadless copper alloy die casting surface defects

A lead-copper alloy, detection method technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of inability to correctly distinguish die castings, waste of resources, low electroplating yield rate, etc., to improve electroplating yield rate, reduce resource waste, The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

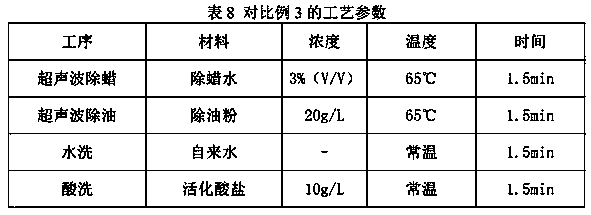

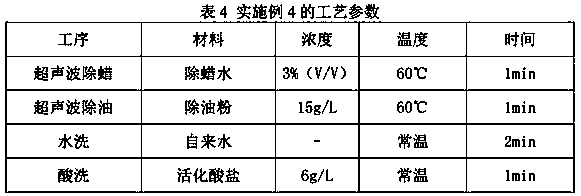

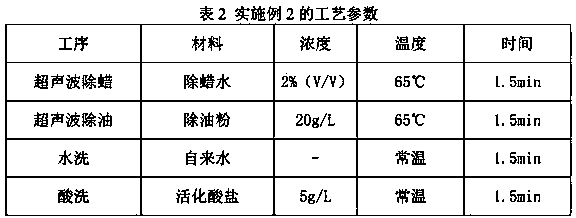

[0028] A rapid detection method for surface defects of lead-free copper alloy die castings, comprising the following steps:

[0029] 1) Ultrasonic wax removal: immerse the lead-free copper alloy die casting in wax removal water, and use ultrasonic cleaning;

[0030] 2) Ultrasonic degreasing: Dissolve the degreasing powder in water to make a degreasing liquid, then immerse the lead-free copper alloy die-casting parts in the degreasing liquid, and use ultrasonic cleaning;

[0031] 3) washing with water;

[0032] 4) Pickling: dissolving the activated salt in water to prepare an activated salt solution, and washing the lead-free copper alloy die casting with the activated salt solution.

[0033] The lead-free copper alloy die-casting parts to be inspected are subjected to the above-mentioned ultrasonic wax removal, ultrasonic degreasing, water washing, and pickling in sequence. After the whole process is completed, the surface defects of the product are judged according to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com