Method for producing lithium iron phosphate

A technology of lithium iron phosphate and manufacturing method, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of stable and difficult bivalent iron, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

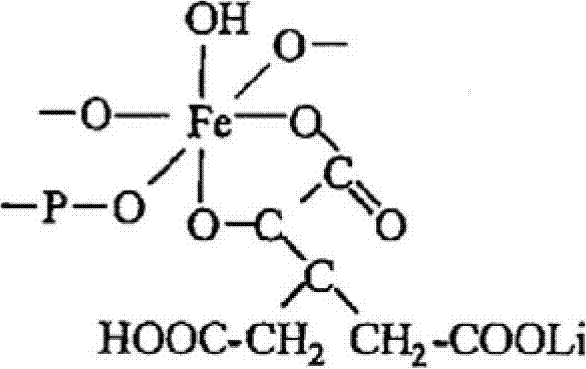

Method used

Image

Examples

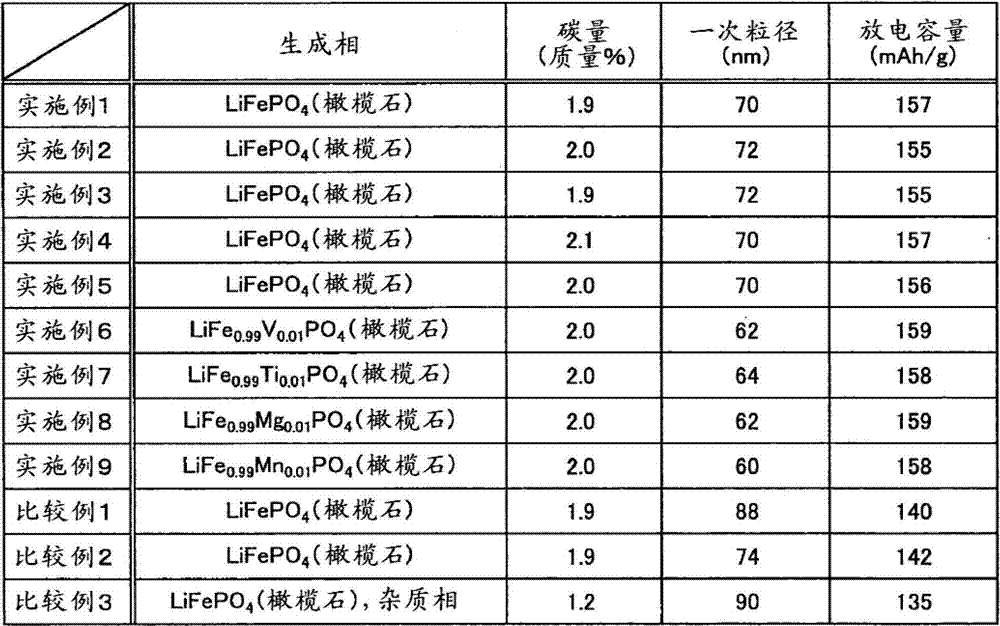

Embodiment 1)

[0083] Dissolve 10 mol of 85% by mass phosphoric acid, 2 mol of citric acid monohydrate, and 5 mol of lithium carbonate in 2000 g of distilled water, and add 10 mol of iron powder (manufactured by JFE Steel Co., Ltd., with an oxygen content of 0.68 mass) to the mixed solution. %, the average particle size is 80μm, and the apparent density is 3.18g / cm 3 ), at a liquid temperature of 25 to 30° C., and reacted for 1 day while stirring under an air atmosphere. The reaction liquid was dried at an inlet temperature of 200° C. using a spray dryer (FOC16, manufactured by Okawara Chemical Industry Co., Ltd.), and a dry powder having an average particle diameter of about 30 μm observed by SEM was obtained. The dry powder was subjected to primary calcination at 400° C.×5 h in a nitrogen flow, and 40 g of ascorbic acid was added to the total amount of the primary calcination as a carbon source, and wet pulverization and mixing were performed by a ball mill. After the obtained mixture was...

Embodiment 1

[0087] In Example 1, except that 2 mol of malic acid was used instead of citric acid monohydrate, lithium iron phosphate was prepared by the same method as in Example 1.

Embodiment 3)

[0089] In Example 1, lithium iron phosphate was prepared by the same method as in Example 1 except that 2 mol of tartaric acid was used instead of citric acid monohydrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com