Antistatic floor wax composition

A technology of anti-static floor and wax composition, which is applied in the direction of polishing composition, chemical instruments and methods, etc., can solve the problems affecting the anti-static function of the floor and the use time, and achieve long-lasting and efficient static dissipation function and excellent anti-static performance , to reduce the effect of functional degradation

Inactive Publication Date: 2012-10-17

SHENZHEN CAPCHEM TECH

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, any ground is not without wear and tear. The daily movement of people in the clean room and t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

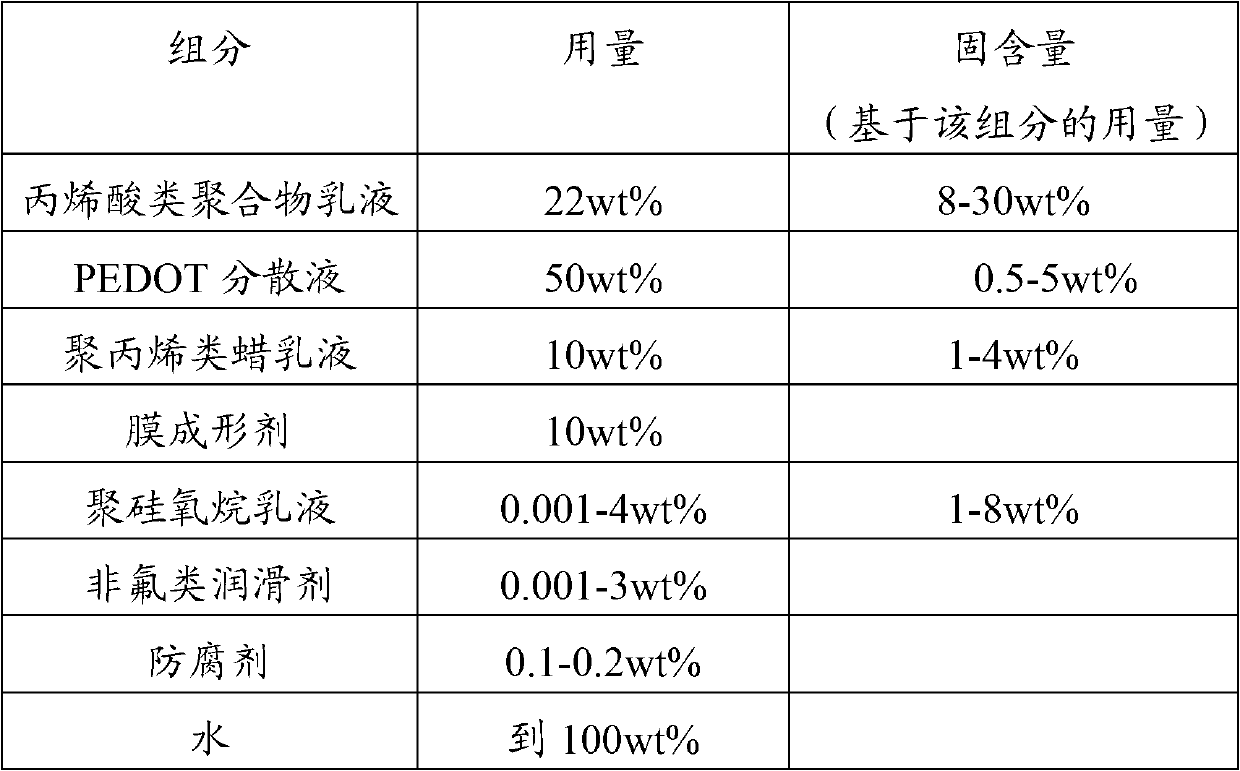

[0040] Example 1

[0041]

Example Embodiment

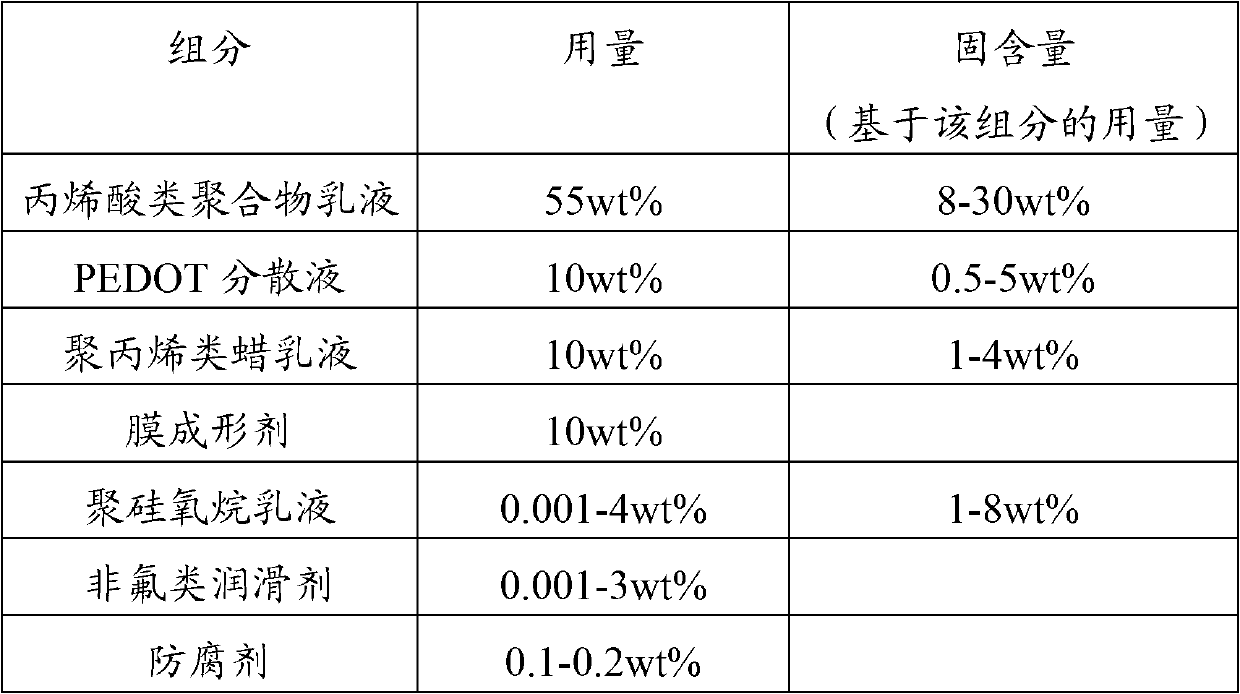

[0042] Example 2

[0043]

[0044]

Example Embodiment

[0045] Example 3

[0046]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses an antistatic floor wax composition which comprises the following components: 22 to 55 wt% of acrylic polymer emulsion, with solid content being in a range of 8 to 30 wt%; 10 to 50 wt% of PEDOT dispersion liquid, with solid content being in a range of 0.5 to 5 wt%; 2 to 15 wt% of polypropylene wax emulsion, with solid content being in a range of 1 to 4 wt%; 2 to 15 wt% of a film forming agent; 0.001 to 4 wt% of polysiloxane emulsion, with solid content being in a range of 1 to 8 wt%; 0.001 to 3 wt% of a non-fluorinated lubricant; 0. 1 to 0.2 wt% of an antiseptic; and the balance being water. PEDOT is a conductive polymer, and the technology of using a conductive polymer in floor wax liquid enables a lasting and highly efficient electrostatic dissipation function to be obtained, accumulation of static to be eliminated, surface static to be released, function degeneration, failure or scraping of electronic components used under electrostatic discharge environment to be reduced and a beautiful, clean, transparent and shiny appearance effect to be maintained.

Description

technical field [0001] The invention relates to the field of floor wax, in particular to a floor wax composition with antistatic function. Background technique [0002] With the development of international trade and the R&D and production of cutting-edge technology products, more and more precision electronics industries have become the mainstream and pillar industries of our country. Due to the influence of geographical environment, transportation environment, climate environment and many other factors, more than 80% of the production bases of most precision electronic equipment and semiconductor products are concentrated in the Pearl River Delta and Yangtze River Delta. Most of the production plants of this type of precision electronics are dust-free purification workshops, which must be constructed in accordance with international standards. The entire purification workshop is equipped with equipment from the floor to the wall, including the tools used in the workshop an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C08L33/00C08L25/08C08L75/04C08L65/00C09G1/16

Inventor 赵大成李付亚

Owner SHENZHEN CAPCHEM TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap