Composition for treating polyethylene (PE) film surface and PE film label

A surface treatment, polyethylene film technology, applied in the direction of synthetic resin layered products, coatings, instruments, etc., can solve the problem of ink falling off and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

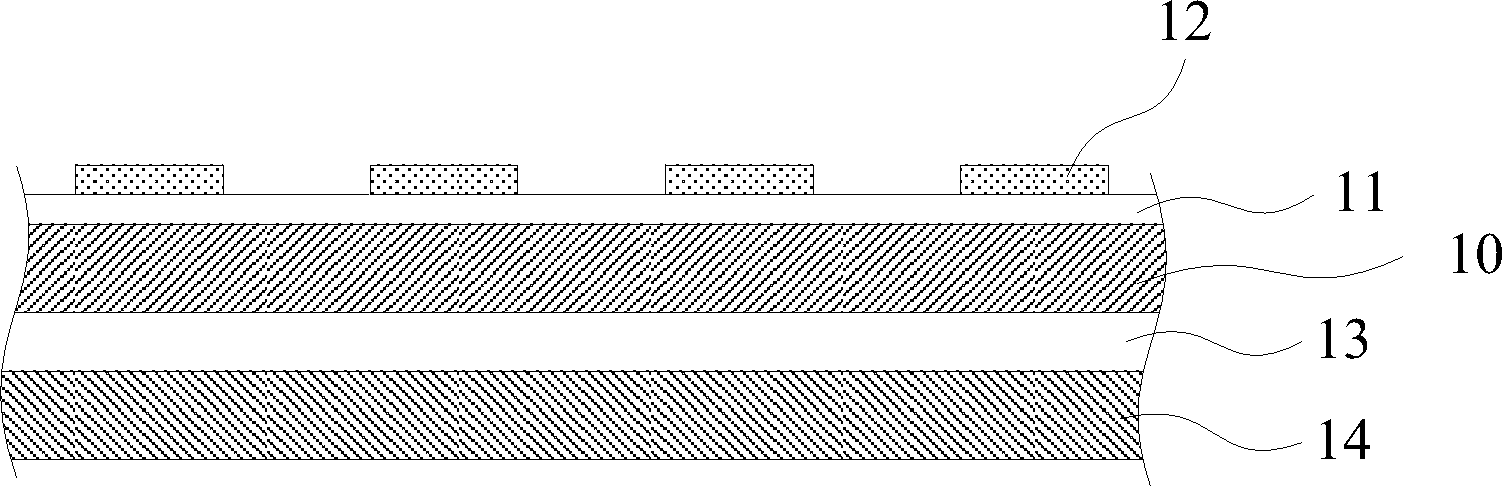

Image

Examples

preparation example Construction

[0064] The preparation of high acid value acrylic polymer A of the present invention:

[0065] (1) After cleaning the glass reaction tank, reflux condenser and feeding pipe respectively, install the reaction system.

[0066] (2) Add 90 grams of methyl methacrylate, 72 grams of n-butyl acrylate, 12 grams of acrylic acid, and 4 grams of hydroxyethyl methacrylate into the reaction tank respectively, and dissolve 0.4 grams of dibenzoyl peroxide in a beaker After adding 20 grams of toluene to the reaction tank, 50 grams of toluene and 200 grams of ethyl acetate were added to the reaction tank.

[0067] (3) The rotation speed of the stirrer is set to 100 rpm to start stirring, and the temperature of the constant temperature water bath is set to 90° C. to start heating.

[0068] (4) After the reflux of the condenser tube occurs, start timing for 1 hour.

[0069] (5) Add 30 grams of methyl methacrylate, 24 grams of n-butyl acrylate, 4 grams of acrylic acid, and 2 grams of hydroxyeth...

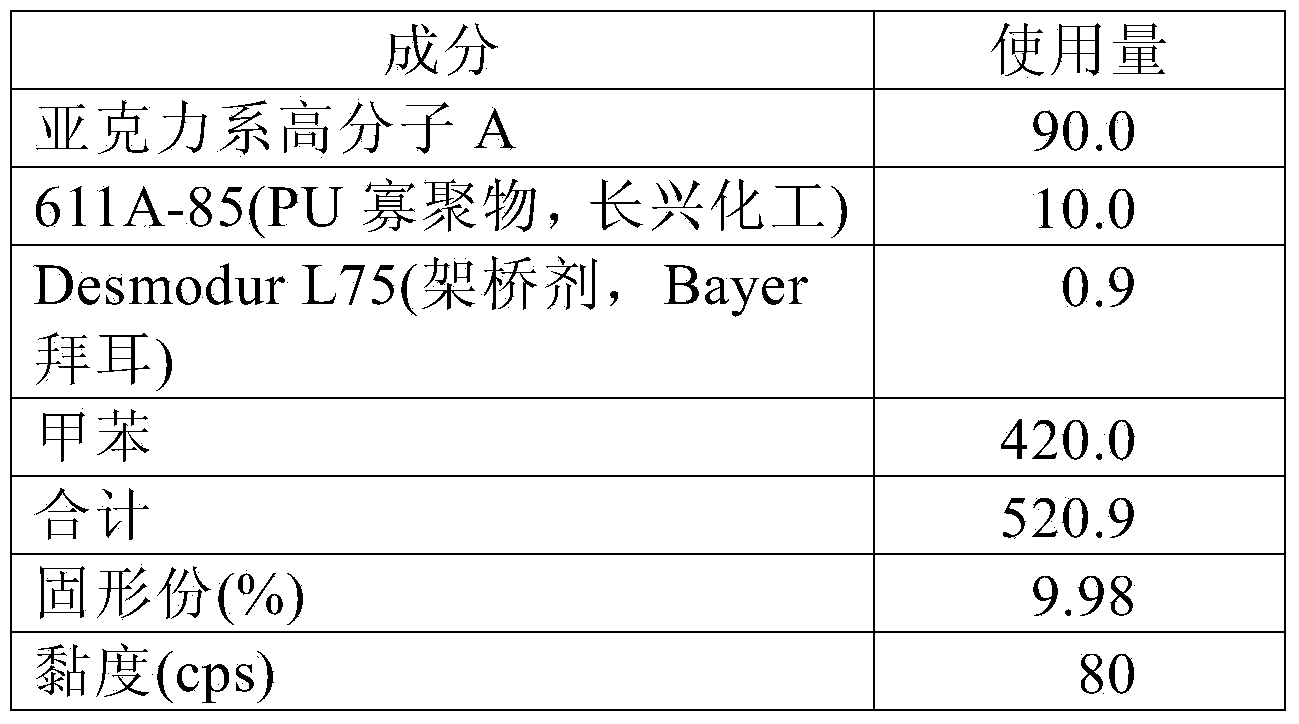

Embodiment 1

[0086] (1) Treatment agent test formula 1:

[0087] Table I:

[0088]

[0089] 611A-85: Polyurethane oligomer, Changxing Chemical Products.

[0090] Desmodur L75: Polyfunctional isocyanate oligomer, product of Bayer.

[0091] (2) Coating of treatment agent test formula 1:

[0092] (2-1) Apply treatment agent test formula 1 on the corona-treated front side of 85 μm low-density polyethylene (LDPE) film sample 1 with a #1 wire-wound rod to form a chemically treated surface layer.

[0093] (2-2) Put sample sheet 1 into an oven with a temperature of 60°C, and take it out after 5 minutes.

[0094] (2-3) Place sample sheet 1 under constant temperature and humidity conditions (23° C., 50% RH relative humidity) for 168 hours before proceeding to the next step.

[0095] (3) UV curable ink coating of sample sheet 1:

[0096] (3-1) Take the #1 wire-wound rod and hand-paint the yellow UV curable ink on the chemically treated surface layer of the PE film sample 1 to form an ink patt...

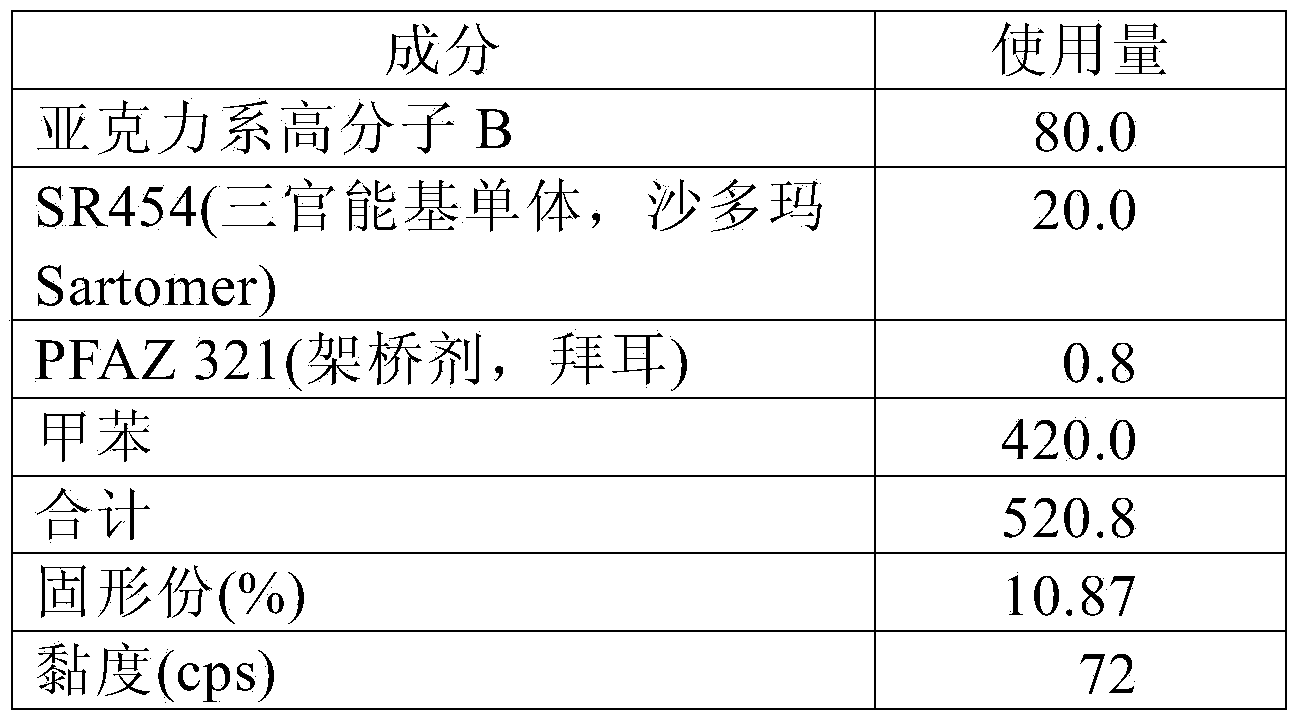

Embodiment 2

[0104] (1) Treatment agent test formula 2:

[0105] Table II:

[0106]

[0107] SR454: Ethoxytrimethylolpropane triacrylate (EOTMPTA), a product of Sartomer

[0108] PFAZ321: Multifunctional ethyleneimine bridging agent, Bayer product.

[0109] (2) Coating of treatment agent test formula 2:

[0110] (2-1) Apply the treatment agent test formula 2 on the corona-treated front side of the 85 μm low-density polyethylene (LDPE) film sample 2 with a #1 wire-wound rod to form a chemically treated surface layer.

[0111] (2-2) Put sample sheet 2 into an oven at 60°C and take it out after 5 minutes.

[0112] (2-3) Place the sample sheet 2 under constant temperature and humidity conditions (23°C, 50%RH) for 24 hours before proceeding to the next step.

[0113] (3) UV curing ink coating of sample sheet 2:

[0114] (3-1) Hand-paint yellow UV curable ink on the chemically treated surface layer of Low Density Polyethylene (LDPE) film sample 2 with #1 wire-wound rod to form an ink pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com