High-temperature carbide furnace capable of producing carbon fibers in large scale

A high-temperature carbonization furnace and carbon fiber technology, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of poor airtightness of the furnace body, poor thermal insulation performance of the furnace type, and can not meet the requirements, and achieves long life, high heating temperature and high performance. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

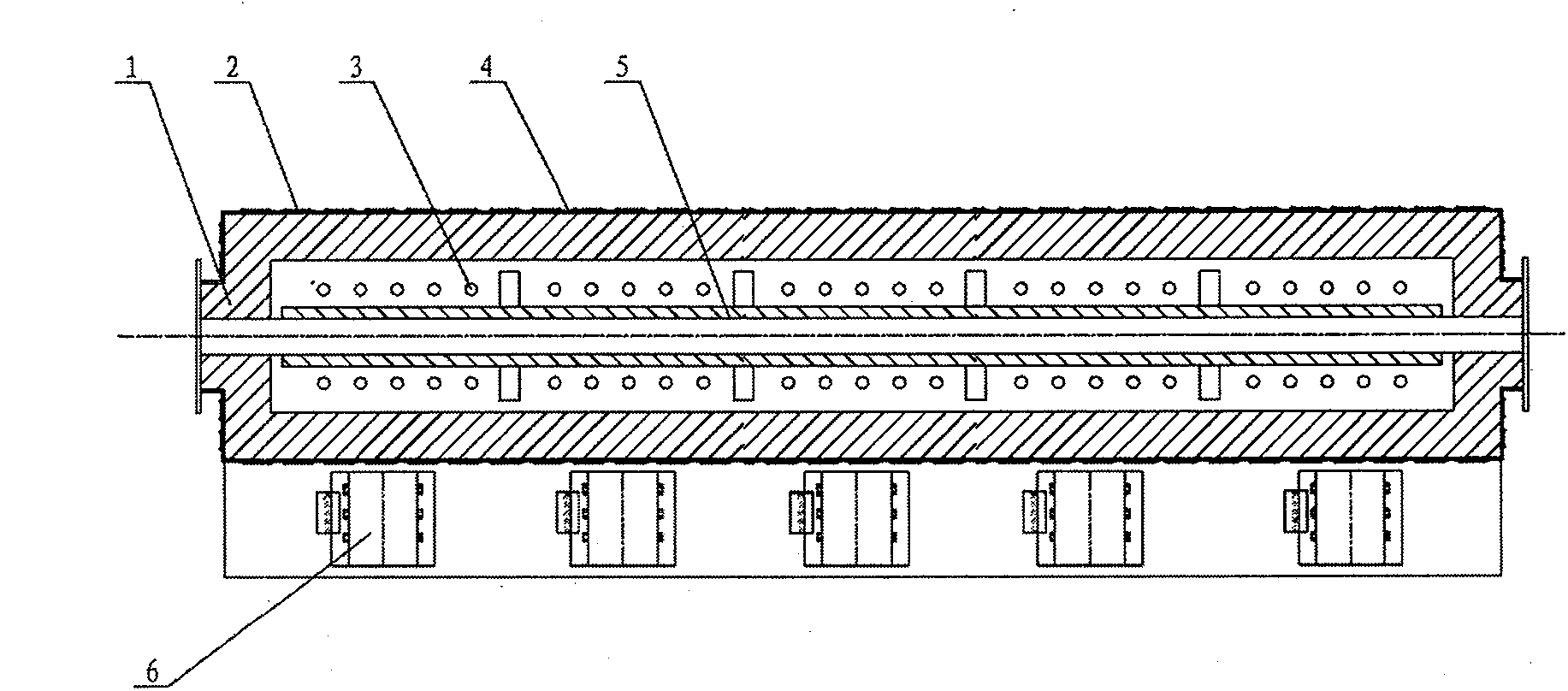

[0012] The present invention is a high-temperature carbonization furnace for large-scale production of carbon fibers, such as figure 1 shown. When the furnace is working, the heating element (3) is energized and heated, so that the temperature of the graphite furnace cavity (5) is raised to 1000-1600°C. The carbon fibers are carbonized in 2-7 temperature zones in the graphite furnace cavity (5). The heat preservation system (1) is located between the heating element (3) and the furnace shell (4), and is composed of 200-400mm thick graphite hard felt and other materials. Most of the heat preservation materials are plate-shaped, and the plates are overlapped. The transformer with taps (6) controls and adjusts the graphite heating element (3) due to the progress of oxidation and the aging of the cross-sectional surface, and the voltage change caused by the increase of heating resistance and the increase of graphite resistance increases to maintain the stability of the heating vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com