Hinge fixing structure, hidden hinge and container

A fixed structure and hidden technology, applied in the field of containers, can solve the problems of strength impact and achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to more clearly understand the objects, features and advantages of the present invention. It should be understood that the embodiments shown in the accompanying drawings are not intended to limit the scope of the present invention, but are only intended to illustrate the essential spirit of the technical solutions of the present invention. It should be noted that in this specification, up, down, left, right, front and rear refer to the directions of each component and the specific structure of each component in the drawings, and are not intended to limit the direction in practical application.

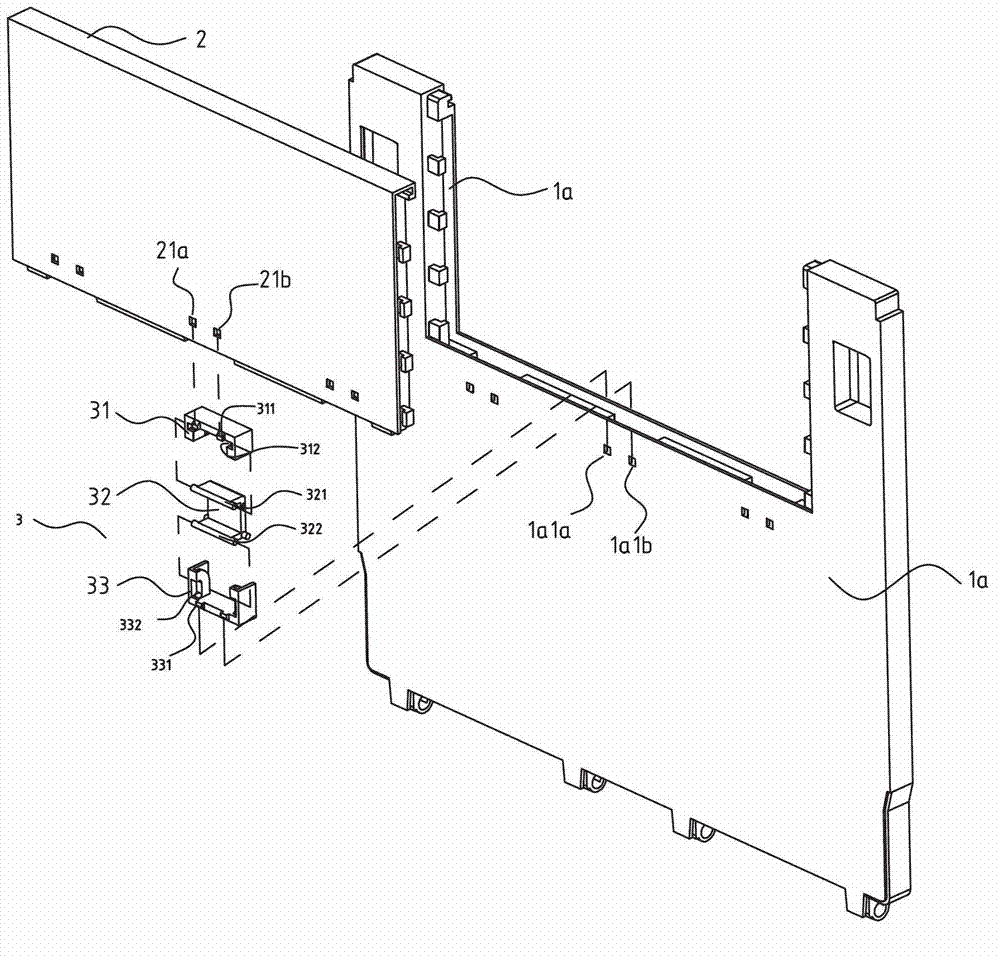

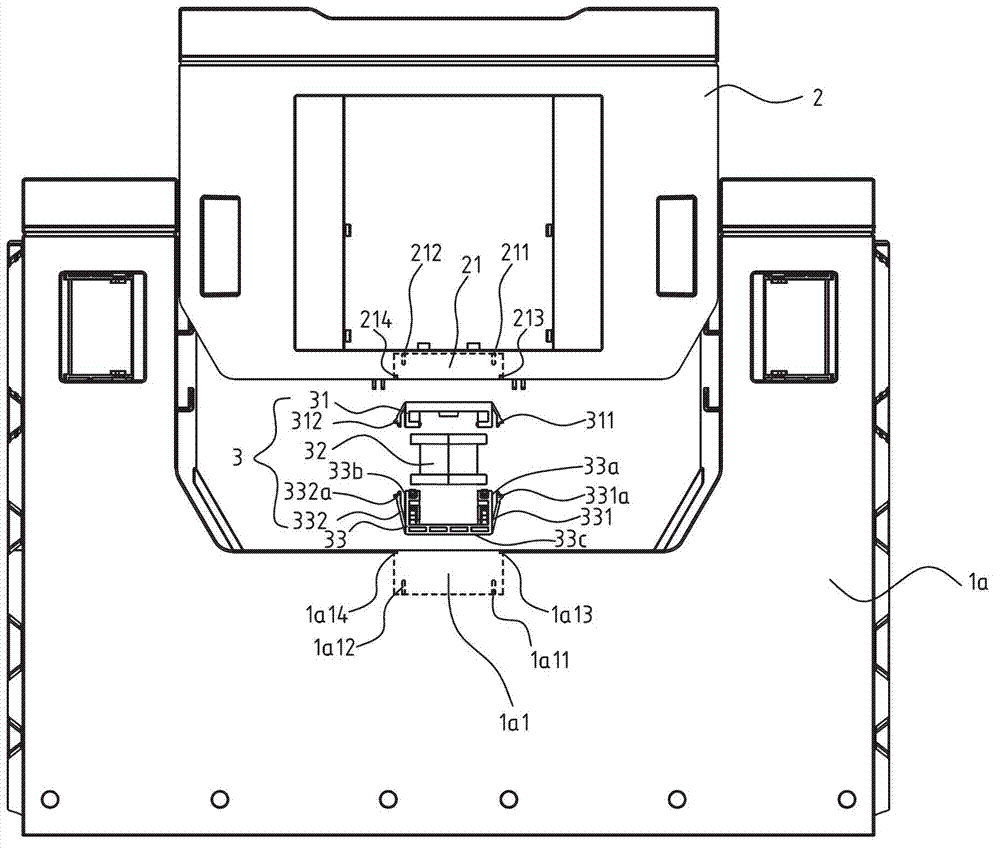

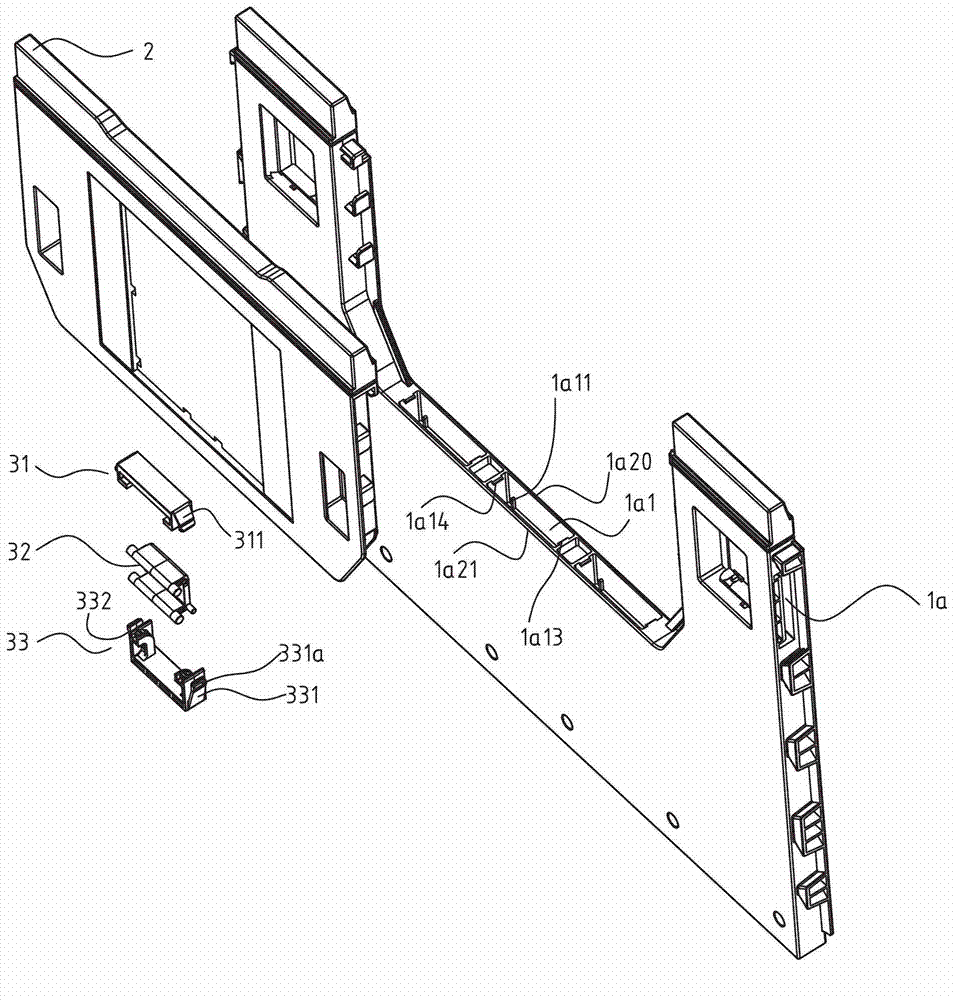

[0042] figure 1 A schematic diagram showing a hidden hinge in the prior art and its installation on a door and a side panel. like figure 1 As shown, the hinge assembly 3 includes a hinge body 32, an upper hinge base 31 and a lower hinge base 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap