Welding rod for wet underwater welding of low alloy steel

A technology of underwater welding and low alloy steel, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high price, low strength, lack of suitable welding materials, etc., and achieve low cost and production process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

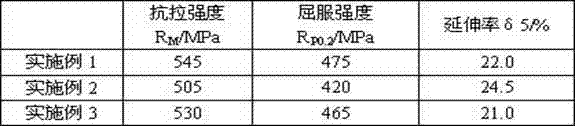

Examples

Example Embodiment

[0022] Below in conjunction with embodiment this patent is further explained and illustrated. But the scope of protection of this patent is not limited to the specific implementation. In each embodiment, H08E steel wire is used as the welding core; ordinary water glass with a solid content of 25% is used as the binder, and the ordinary welding rod is used to press-coat the welding rod; finally, the waterproof insulating varnish is coated on the surface of the coating. The raw materials of the drug skin meet the requirements of the technical scheme. High carbon ferromanganese: Mn is 79%.

[0023] Table 1 Composition of drug skins in Examples 1-3.

[0024] Raw material name rutile marble Potassium feldspar microcrystalline cellulose Titanium dioxide High carbon ferromanganese iron powder total Example 1 42% 8% 16% 6% 10% 12% 6% 100% Example 2 40% 7% 15% 10% 7% 9% 12% 100% Example 3 48% 5% 20% 5% 6% 8% 8% 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap